FEATURE

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 5

4 0

6

USINGWORKLOAD-EMISSIVITYFACTORSTOPROJECT

HEATINGRATES INAVACUUMFURNACE

Emissivity is a term used to define the ability of a surface to emit and absorb radiation.

At any given temperature, the emissivity of a body (or surface) equals its absorptivity.

Reàl J. Fradette and Trevor Jones,*

Solar Atmospheres Inc.

D

evelopment work on a vacuum carburizing process

revealed the need to better understand the effect of

workload surface emissivity and the proper use of

dummy thermocouple test blocks. The process involved car-

burizing areas of a partially copper-plated alloy steel part;

areas of the part that were not to be carburized were cop-

per plated. Because part configurationmade it impossible to

place a thermocouple inside, a dummy test block made of

carbon steel with approximately the same cross section as

the workpiece was used for the process thermocouple with-

out proper consideration (as determined subsequently) of

the test block surface.

Using the test block as the control, carburizing was

initiated when it reached the predetermined temperature.

Examination of the part at the end of the test showed that

the depth of carburized case was shallow in areas that were

not plated. This indicated that the carburizing cycle did not

hold the part at the correct temperature long enough before

carburizing. Thus, it was concluded that when using dummy

test blocks to control process times and temperatures, many

factors must be considered including surface emissivity. This

led to evaluating the effects of surface condition and work-

piece size on emissivity and time to heat to temperature.

PART SURFACE EMISSIVITY

In a vacuum furnace, heat is imparted to a workload

via radiation from the furnace heating elements. In practice,

most materials and surfaces are “gray bodies,” having an

emissivity factor less than 1.0. For practical purposes, it is

assumed that a good reflector is usually a poor absorber.

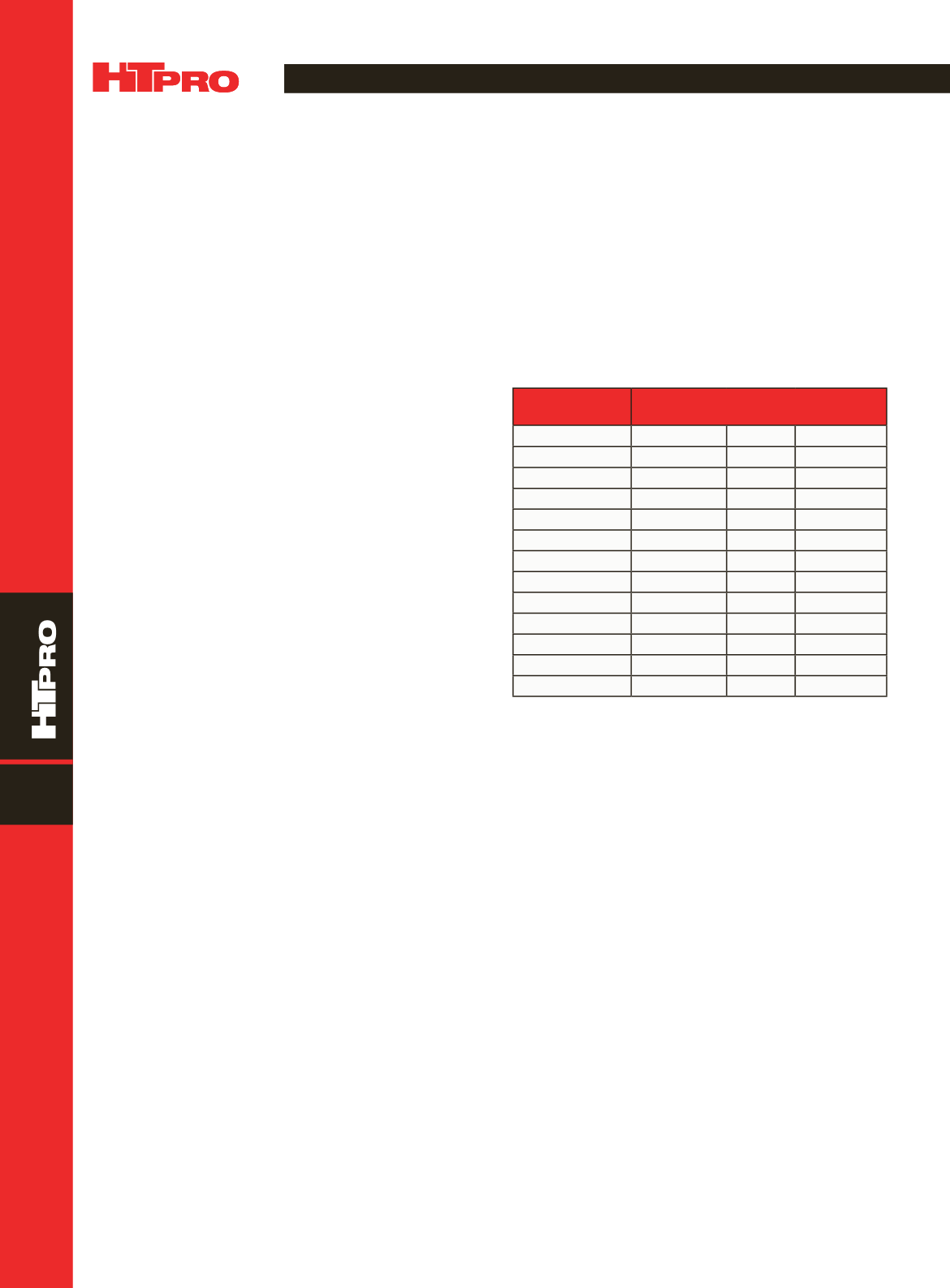

The surface condition of amaterial can greatly affect its

ability to absorb radiant energy. To heat the same material

with equal cross section and mass to final temperature can

take up to twice as long, depending on surface condition. Ta-

ble 1 shows the approximate emissivities of various metals

and surface conditions.

In vacuum furnace heating, several complex factors af-

fect the total time it takes for materials to reach uniformpro-

cess temperature, including load weight, part cross section,

and heating rate. As stated previously, emissivity is also an

important factor directly affecting the heat absorption capa-

bility of the material being processed.

Knowing the emissivity of a material is most critical

when using separate dummy thermocouple blocks to sim-

ulate actual workload temperature. The thermocouple

block must not only represent the average cross section of

parts, but also must represent the surface condition (color,

roughness, or amount of oxidation) of the material being

processed.

TEST PROCEDURE

To illustrate the importance of the emissivity factor in

load heating and dummy thermocouple blocks, six carbon

steel blocks with different surface conditions were prepared

for testing. Blocksmeasured 2.5

×

2.5

×

2.5 in., with a 0.093 in.

diameter hole drilled 1.25 in. deep at the center into which

a thermocouple was inserted. Block surface modifications

included oxidized, grit blasted, copper plated, nickel plated,

polished shiny, and chrome plated (Fig. 1).

Dummy blocks were loaded into a workbasket with

generous spacing between blocks and relatively equal dis-

tance from the heating elements. Thermocouples were

inserted into the blocks (Fig. 2), and the workbasket was

placed into the furnace. Process cycle steps were as follows:

TABLE 1 — EFFECT OF SURFACE CONDITION

ON EMISSIVITY OF SELECT METALS

Metal

Surface condition

Polished Rough Oxidized

Aluminum

0.04

0.055 0.11–0.19

Brass

0.03

0.06–0.2

0.60

Chromium

0.08

--

0.17

Copper

0.018–0.02

--

0.57

Gold

0.018–0.035

--

--

Steel

0.12–0.40

0.75

0.80–0.95

Stainless steel

0.11

0.57

0.80–0.95

Lead

0.057–0.075 0.28

0.63

Nickel

0.045–0.087

--

0.37–0.48

Silver

0.02–0.035

--

--

Tin

0.04–0.065

--

--

Zinc

0.045–0.053

--

0.11

Galvanized iron

0.228

--

0.276

*Member of ASM International and Heat Treating Society