FEATURE

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 5

4 4

10

T CHNICAL SPOTLIGHT

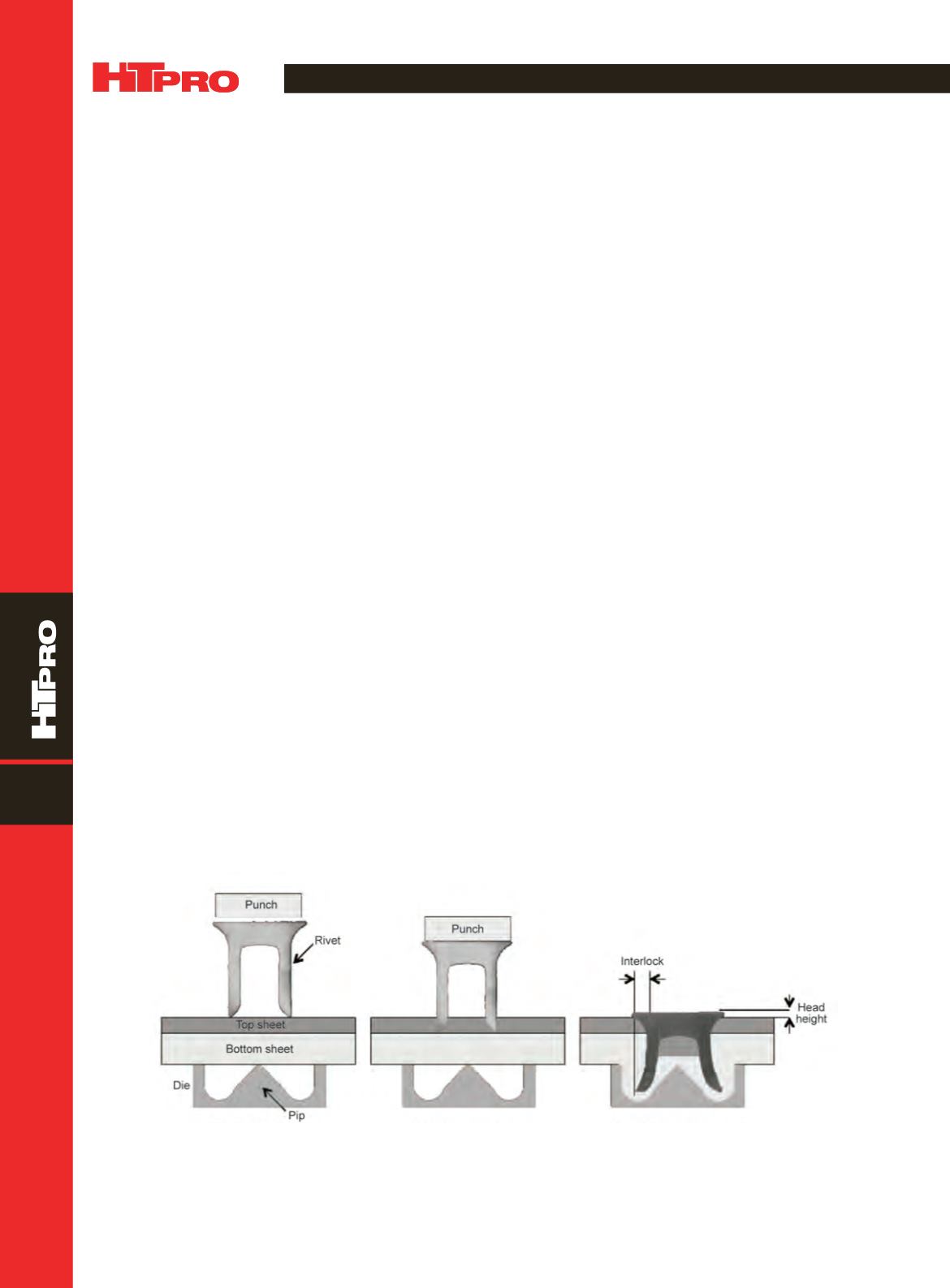

by forcing (piercing) a semi or fully tubular rivet through top

sheet(s) using a robotically actuated C-frame containing

a servoelectric punch and opposing die. The die forces the

rivet to flare into the bottom sheet without perforating the

sheet, producing a significant interlock that provides joint

strength. The potential for corrosion isminimal because pre-

viously applied coatings are preserved in the process.

Joining steel and aluminum using SPR is well estab-

lished and widely used in the automotive industry. Increas-

ing interest in using very high-strength steel alloys for vehicle

construction offers an opportunity to extend the use of cur-

rent SPRby further developing rivetmaterial. SPR technology

can be applied to a wide range of materials using rivets with

different hardness levels depending on the application. For

example, rivets with low and medium hardness are used to

join soft materials, providing a large degree of flare, which

creates a largemechanical interlock (more than 0.4mm) that

resists rivet pull through and produces a strong joint. For join-

ing high-strength steels, only 0.2 mm of rivet flare is required

to resist rivet pull through and produce a strong joint.

RIVET MATERIAL DEVELOPMENT

Joining very high-strength steels requires using rivets

at the top end of the rivet-hardness scale and with improved

mechanical properties, which enable producing these chal-

lenging joints. Rivet development is of particular interest for

A

utomotive manufacturers are increasing their use of

high-strength steel with lightweight aluminum body

components to achieve stringent Corporate Average

Fuel Economy (CAFE) standards through weight reduction,

without compromising passenger safety and vehicle dura-

bility

[1]

. Joining aluminum to different materials by welding

presents challenges due to the formation of oxides and dif-

ferent material melting points

[2]

. However, it is possible to

produce joints with adequate strength and durability using

mechanical spot-joining methods, which enables using dif-

ferent material combinations in vehicle design.

SELF-PIERCE RIVETING

One mechanical spot joining technique of particular

interest is self-pierce riveting (SPR), which is used in the con-

struction of the 2015 Ford F-150 pickup truck

[3]

. SPR provides

a robust joint, which often outperforms clinching and spot

welding under both static and fatigue conditions, while pro-

viding fast cycle times, zero waste, and the ability to join dif-

ferent material combinations

[4]

.

Rivets used in automotive applications are cold forged

from a range of steel wire alloys. AISI 10B37 is one of the

most widely used grades (Table 1). Rivets are heat treated to

achieve a fully martensitic microstructure, which provides

the high strength required for a successful joint. A schematic

of the joining process is shown in Fig. 1. The joint is formed

ADVANCINGSELF-PIERCERIVET TECHNOLOGY

THROUGHALLOYDEVELOPMENT

Stephen Van Hall and Kip Findley,*

Colorado School of Mines, Golden

*Member of ASM International

Fig. 1 —

Schematic showing the SPR process of joining two sheet materials: (a) Setting stack up, (b) piercing the top sheet, and (c) flaring

into bottom sheet. Joint strength is provided by the mechanical interlock between the rivet and top sheet.

(a)

(b)

(c)