TECHNICAL SPOTLIGHT

SURFACE COATINGS OFFER PROTECTION

IN HARSH ENVIRONMENTS

P

lasma spray coatings are increasingly used to solve a

range of engineering issues for military suppliers, in-

cluding heat, wear, electrical insulation, and the re-

placement of more harmful coatings. Plasma spray coatings

now offer the potential to solve electro-mechanical interfer-

ence on composites.

Novel surface technology derived from experience in the

nuclear industry is enabling engineers to solve many perfor-

mance issues in a range of harsh environments. Zircotec Ltd.,

UK, originally developed its technologies for use in nuclear

reactors. During the last decade, its coatings have been used

in several other applications, including orthopedic implants,

and the company has expanded into the defense sector with

a greater emphasis on heat protection. Anti-abrasive coatings,

electrically insulating formulas, and cadmium-free options are

also available.

Process capability

Plasma spray technology works by injecting powder

particles into a nitrogen or argon plasma with a flame tem-

perature of roughly 20,000K and a gas velocity of Mach 2-3.

Therefore, particles spend a short time in the flame while

spray parameters are adjusted, and an extensive range of

materials may be sprayed. These range from nylon at the

lower end of the temperature spectrum to beryllia at the

top. Provided the material does not sublime nor is transpar-

ent to UV, particles will melt and quench as splats onto the

substrate. Control of overall spray parameters to predefined

tolerances ensures that coatings are evenly built-up in mul-

tiple thin layers—a method that helps to reduce stress in the

final coating.

A range of plasma spray coatings is already being suc-

cessfully applied to metallic components, reducing metal

surface temperatures by more than 170°C in some applica-

tions such as automotive exhaust systems. Zirconia has a

thermal efficiency of less than 1.7 W/m K (compared with 4

W/m K for alumina), enabling coatings that are highly effec-

tive at inhibiting surface heat radiation. This coating is also a

suitable choice for thermal management.

The defense sector has adopted another technology—

a flexible ceramic supplied on an aluminum foil. ZircoFlex

solves heat issues without components needing to be re-

moved from service for spraying, making it easy to retrofit,

even during use. ZircoFlex is a flexible ceramic heat shield

material, offering superior thermal barrier performance at

minimal weight and thickness. Supplied in sheets, it can be

cut, folded, and bent to fit any shape and offers surface tem-

perature reductions of 64%. The newest derivative, ZircoFlex

FORM, will enable structural heat shields to be made from a

flexible and bendable sheet.

The material is produced as a thin aluminum or gold

backed foil that is easily bent and manipulated to suit dif-

ferent geometries, and can even be folded tightly through

180° without damaging the thermal barrier. It weighs only

0.46kg/m

2

(0.23kg/m

2

for ZircoFlex Gold). The material is ex-

tremely thin—at 0.25 mm overall, it requires only minimal

space for installation. In addition, the metal backing makes

it robust, easy to handle and cut, and simple to install by

hand or machine.

Enabling greater use of composites

Zircotec has pioneered the use of plasma spray coat-

ings on composite substrates to enable use in environments

where they would have previously failed due to delamina-

tion or heat damage. Formula One racing is an area where

these coatings are increasingly popular to prevent such

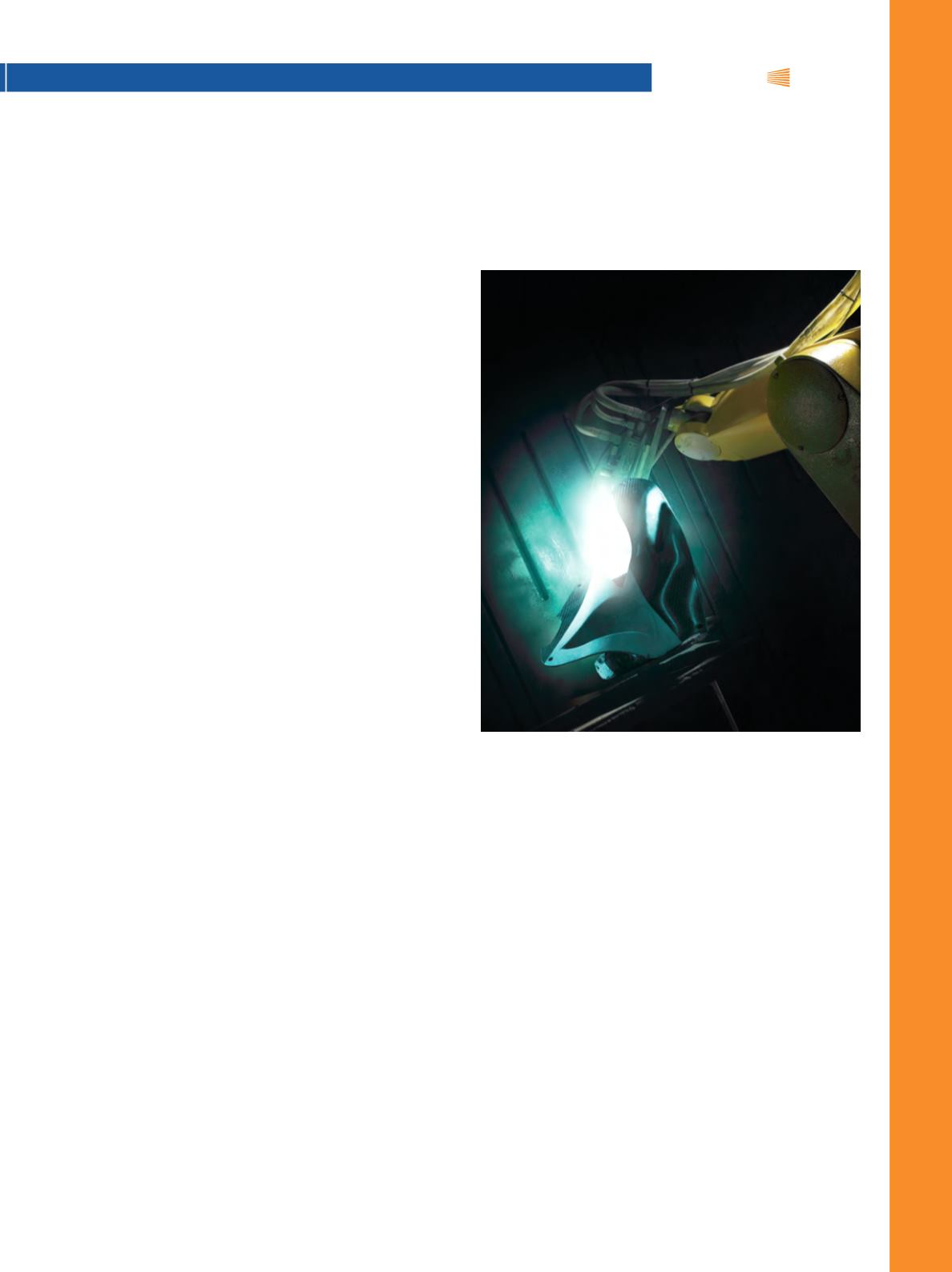

Fig. 1 —

Zircotec’s plasma spraying process safely coats

composites, enabling use in high temperature environments.

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y 2 0 1 5 |

i T S S e

1 3

iTSSe

|

TSS