JTST

HIGHLIGHTS

high temperatures in contrast to YSZ. Mg-Al-spinel deposition

by SPS results in columnar-structured coatings, which were

tested for their thermal cycling lifetime. The influence of

substrate cooling during the spray process on thermal cy-

cling behavior, phase composition, and stoichiometry of

Mg-Al-spinel was also investigated.

“Tailoring the Spray Conditions for Suspension Plasma

Spraying”

A. Joulia, W. Duarte, S. Goutier, M. Vardelle, A. Vardelle,

and S. Rossignol

Plasma spray using suspensions as liquid feedstock al-

lows deposition of finely structured coatings with improved

properties compared to that of coatings deposited by con-

ventional plasma spray techniques. The evaporation of the

solvent, acceleration, heating, and melting of fine solid par-

ticles within the plasma jet take place in a shorter time, as

the substrate is located closer to the plasma torch when a

mono-cathode mono-anode plasma torch is used, while

liquid material processing globally consumes more energy

than powder materials. In this study, a large range of plasma

spray conditions were used to achieve yttria-stabilized zir-

conia coatings by suspension plasma spray. The properties

of the plasma jet

(velocity, enthalpy,

and stability) as well

as those of droplets

(trajectories, num-

ber, and size) and

particles (velocity)

were measured and

correlated to the

coating microstruc-

ture. The operating

conditions

neces-

sary for obtaining

disk-shape

splats

and achieving ho-

mogeneous coatings are described including plasma jet

properties and substrate parameters.

“Interface Characterization and Bonding Mechanisms of Cold

Gas-Sprayed Al Coatings on Ceramic Substrates”

R. Drehmann, T. Grund, T. Lampke, B. Wielage, K. Manygoats,

T. Schucknecht, and D. Rafaja

Research aims to contribute to the understanding of

adhesion mechanisms, which take effect at the interface of

cold gas-sprayed metallic coatings on ceramic substrates.

Former investigations reveal the possibility to deposit

well-adhering metallic coatings on atomically smooth ce-

ramics, meaning that mechanical interlocking is not al-

ways a necessary precondition for bonding. A combination

of recrystallization processes induced by adiabatic shear

processes and heteroepitaxial growth might explain high

observed adhesion strengths. The present work examines

the interface area of cold gas-sprayed aluminum on various

ceramic substrates using SEM and HRTEM. Besides sintered

corundum plates, single-crystalline sapphire substrates

with defined lattice orientations were used as substrates for

coating deposition. In addition to Al2O3 substrates, alumi-

num coatings were also deposited on AlN, Si3N4, and SiC

to investigate whether different amounts of ionic bonds in

these substrate materials influence the substrate/coating

interface formation.

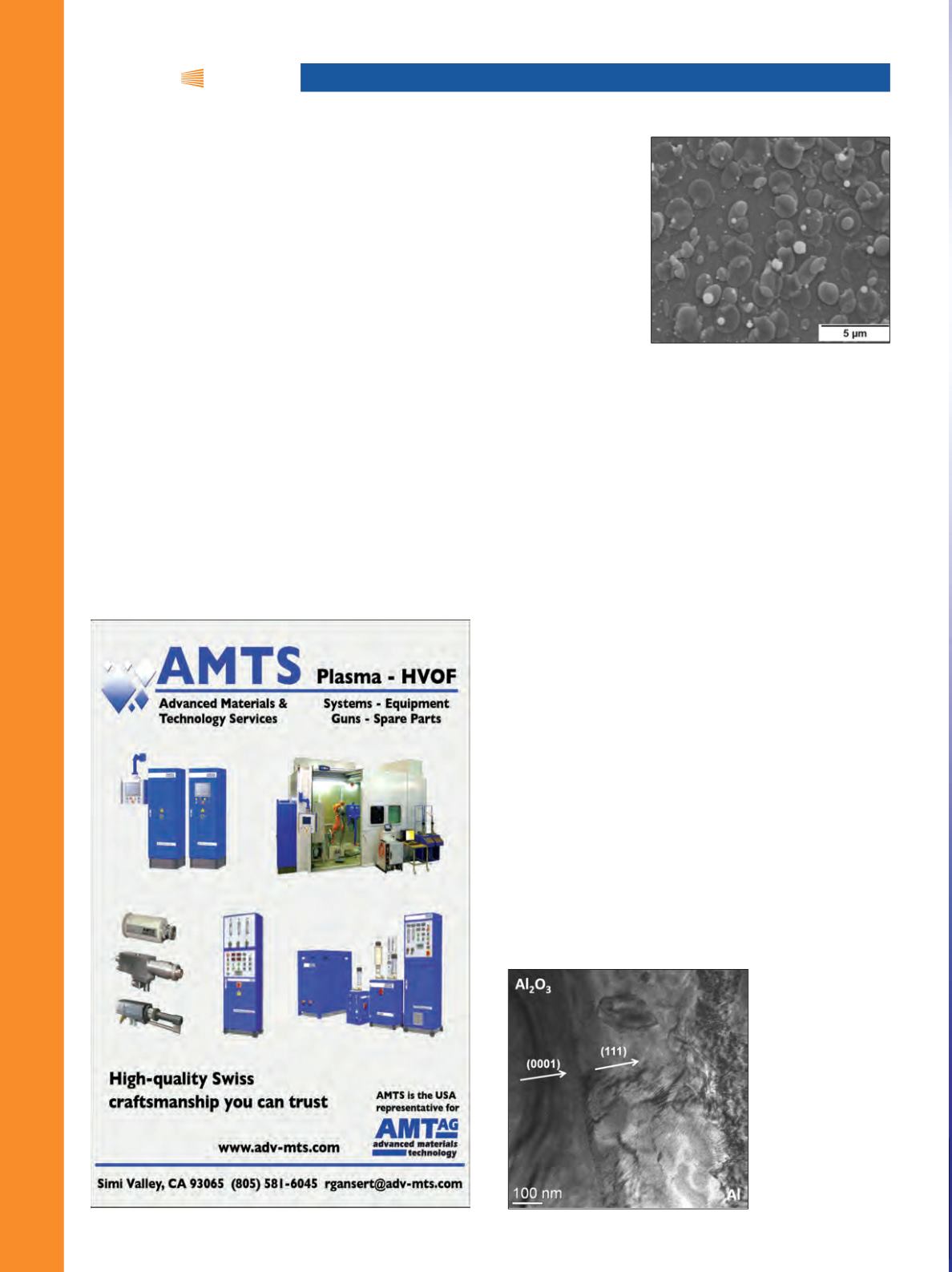

Interface of

(0001)-oriented

sapphire with

(111)-oriented PVD Al

coating (TEM image).

Directions normal

to the lattice planes

(determined by XRD

pole figures) are

indicated by arrows.

SEM micrograph of YSZ splats collected

at 30 mm from nozzle exit. Arc current:

600 A. Plasma gas composition: Ar

(77%)-He (33%). Substrate: 400°C.

i T S S e

| a d v a n c e d m a t e r i a l s & p r o c e s s e s | F E B R U A R Y 2 0 1 5

1 6

iTSSe

|

TSS