above the Earth’s surface. This generated a re-entry velocity

exceeding 20,000 mph. For extra strength and stiffness, the

heat shield features a titanium backbone structure enabling

Orion to withstand landing loads of 300,000-400,000 lb. The

December flight tested all of Orion’s re-entry systems—in-

cluding testing the heat shield, jettisoning the forward bay

cover, and deploying parachutes—and gauged the effective-

ness of the software driving numerous functions across mul-

tiple systems.

Data collected from Exploration Flight Test-1 provides

engineers with information about fluctuations between the

temperatures and pressures across the heat shield during

re-entry, Avcoat performance, and accelerations and strain

during splashdown.

Even with deployment of 11 parachutes to help slow the

spacecraft to a safe splashdown, the heat shield must protect

the crew and capsule from landing loads and turbulent sea

conditions, which could vary significantly during different mis-

sions. Comprehensive test flight data, including information

about the heat shield, will guide design decisions most critical

to crew safety, ultimately lowering risks and costs for future

space missions.

For more information:

Allison Rakes is Orion public

relations officer, Lockheed Martin Space Systems Co., 6801

Rockledge Dr., Bethesda, MD 20817-1803, 303.977.7135,

allison.m.rakes@lmco.com,

lockheedmartin.com.

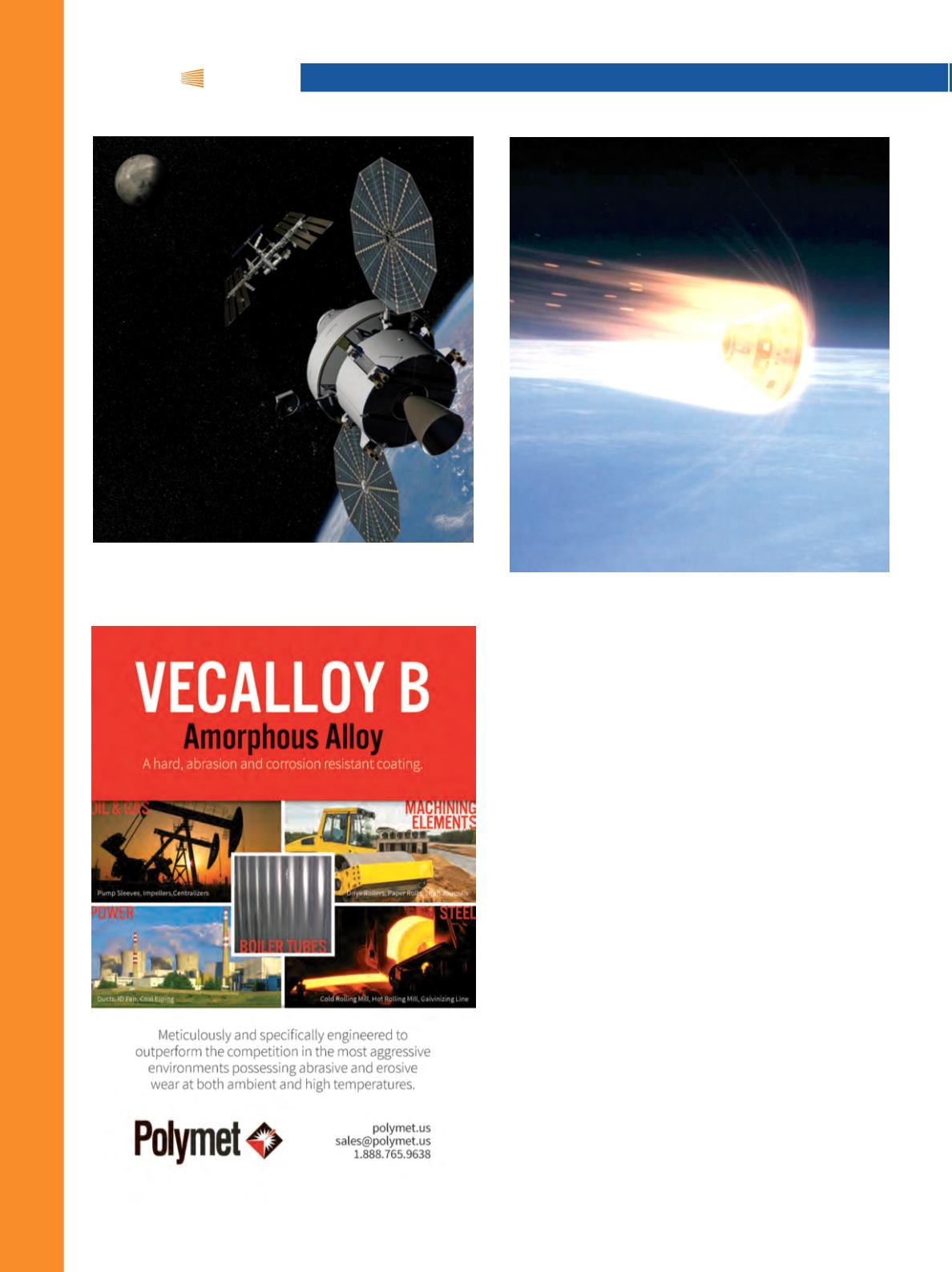

Fig. 3

—The OrionMulti-Purpose CrewVehicle is intended to carry

a crew of up to four astronauts to destinations at or beyond low

Earth orbit.

Fig. 4

— During re-entry into Earth’s atmosphere, the Orion heat

shieldprotected the vehicle fromexternal temperatures of 4000°F.

i T S S e

| a d v a n c e d m a t e r i a l s & p r o c e s s e s | F E B R U A R Y 2 0 1 5

1 2

iTSSe

|

TSS