FEATURE

L

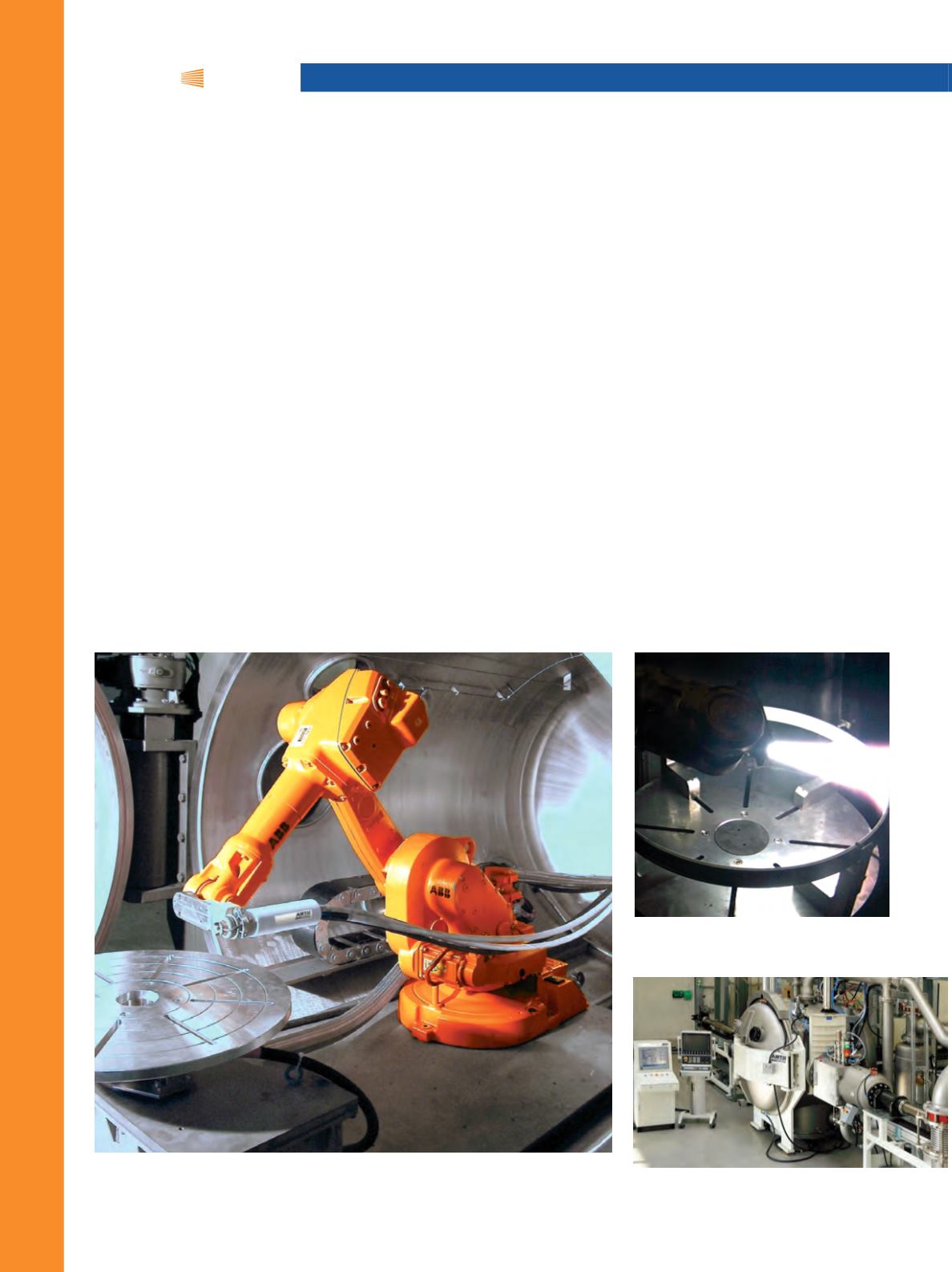

ow pressure and vacuum plasma spray technologies are

making headway in many emerging industries, along

with their primary use in commercial and military aero-

space gas turbine engine applications. Vacuum plasma has

also been implemented in biomedical and electronics appli-

cations. Figures 1 and 2 show a vacuum plasma system, while

Figs. 3 and 4 show a low pressure coating system (LPCS) man-

ufactured by AMT AG.

Both systems pump down the atmosphere to <0.1 torr

and backfill to processing pressure in a short time. Stable at-

mospheric pressure regulation and reliable part handling are

critical for proper coating quality. Therefore, state-of-the-art

control software and hardware is used aswell as a new robotic

and computer numerical control (CNC) technique.

Low pressure and vacuum plasma spray

coating properties

Low pressure and vacuum plasma spray produce coat-

ings with better performance properties than those made

by traditional air plasma spray (APS). By carefully controlling

the processing environment, exceptional coating properties

with regard to microstructure (porosity, oxide content, den-

sity), phase composition, and mechanical attributes may be

achieved. It is also possible to hold oxide content to less than

1% and reach coating densities near 99%.

Plasma coatings of NiCrAlY, shown in Fig. 5, are produced

in a low pressure plasma spray atmosphere. These coatings

exhibit enhanced oxidation protection and increased resis-

tance to spallation in gas turbine engines.

Low Pressure and Vacuum Plasma

Spray Build Better Coatings for Engine

Applications

Ludwig Guggenheim, Ralph Herber, and Silvano Keller, AMT AG, Dottingen, Switzerland

Robert Gansert*, Advanced Materials & Technology Services Inc., Simi Valley, Calif.

*Member of ASM International and ASM Thermal Spray Society

Fig. 1

— Vacuum plasma spray system.

Fig. 2

— Vacuum plasma spray in

operation.

Fig. 3

— Low pressure coating system

(LPCS).

iTSSe

|

TSS

i T S S e

| a d v a n c e d m a t e r i a l s & p r o c e s s e s | F E B R U A R Y 2 0 1 5

8