CASE STUDY

ORION HEAT SHIELD HANDLES extreme temps

H

ave you ever imagined how hot it would be at the

Earth’s core? What about stepping on molten lava?

The Orion spacecraft built by Lockheed Martin endured

those temperatures (and higher) when re-entering the terres-

trial atmosphere late last year. Boosted to an altitude of 3604

miles, Orion fell back to Earth on December 5 at nearly 20,000

mph. During re-entry, Orion’s heat shield protected the vehicle

from external temperatures of 4000°F—nearly half the heat of

the sun’s surface.

The heat shield is the forebody or wind-facing side of an

aeroshell system. Due to its size, the aeroshell experiences

tremendous entry loads as a result of dynamic pressures from

the atmosphere and the high velocity of vehicle descent. Lock-

heed Martin constructed all eight of the aeroshells that have

protected NASA’s Mars-bound space-

craft—but Orion is unique.

At 16.5 ft in diameter, it is the

largest composite heat shield ever

made. Orion is also designed for

long-duration, human exploration

of deep space. That means the

shield will play a critical role in pro-

tecting future astronauts on their

return to Earth.

Not only is the new heat shield

the largest ever built, it also fea-

tures a unique resin system that can

withstand higher temperatures and

landing impact. After testing in ex-

treme environments and simulating

re-entry, engineers verified that the

thermal insulator on the outside of the composite material

could be thinner, making the spacecraft lighter and allowing

more payload to join the mission. The resin was developed

by the Lockheed Martin Orion thermal protection system

team in partnership with TenCate Advanced Composites,

Morgan Hill, Calif.

The heat shield is built around a titanium skeleton and

carbon-fiber skin that gives the shield its shape and provides

structural support for the crew module during descent and

splashdown. A fiberglass-phenolic honeycomb structure fits

over the skin, and each of its 320,000 cells is filled with a ma-

terial called Avcoat. The surface is designed to burn away, or

ablate, as thematerial heats up, rather than transfer heat back

into the crew module. At its thickest, the heat shield is 1.6-in.

thick, and about 20% of the Avcoat will erode as Orion travels

through Earth’s atmosphere.

Test parameters

During the high orbital test flight, Orion traveled a total

of 60,000 statute miles and as far out as 3600 statute miles

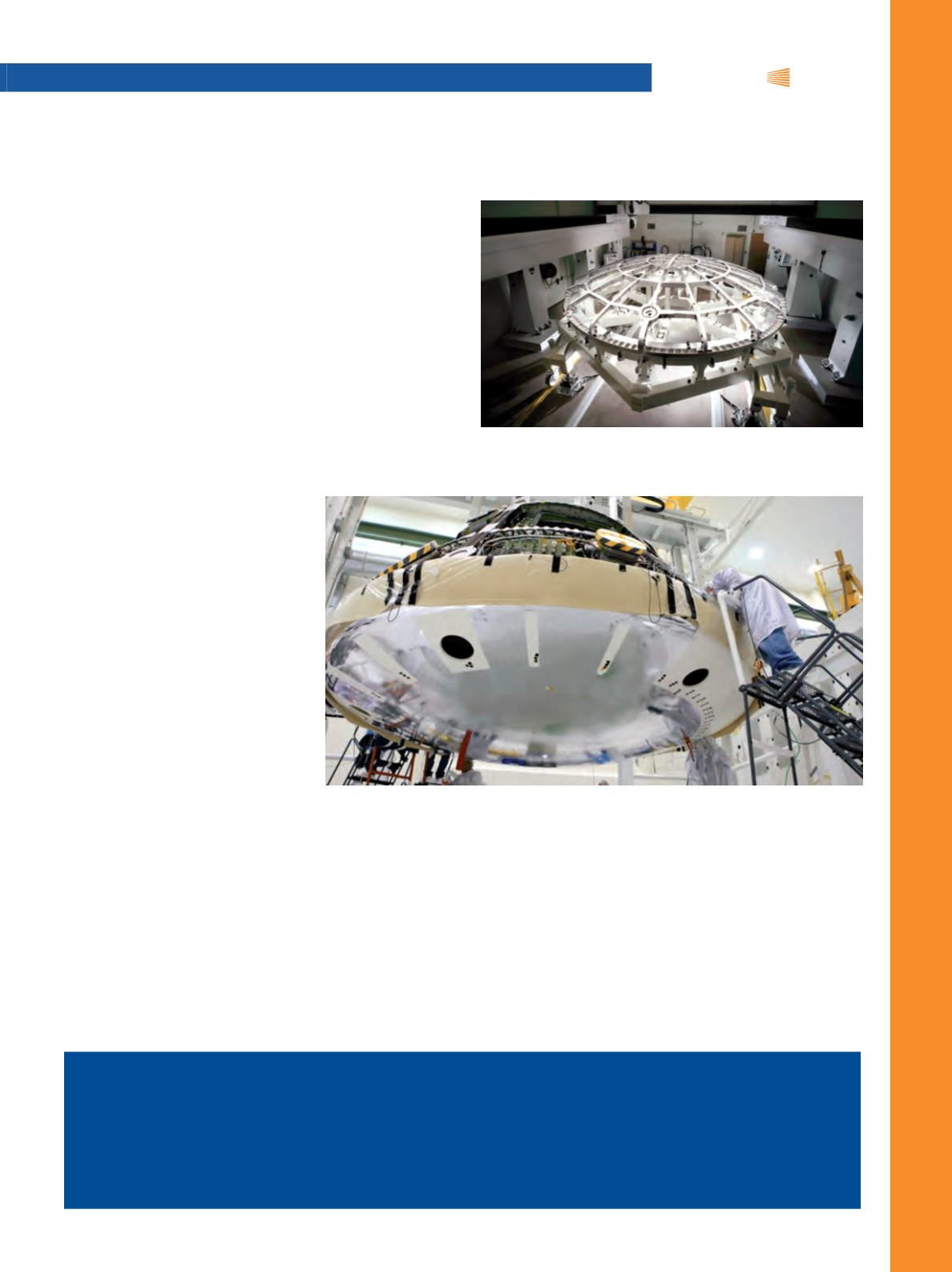

Fig. 1

— At 16.5 ft in diameter, the Orion heat shield is the largest

composite version ever made.

Orion heat shield details:

• The Orion heat shield is the largest ever made.

• The melting point for titanium is about 3000°F and the surface temperature of the sun is about 10,000°F.

Orion can handle temperatures around 5000°F.

• Orion must withstand landing loads of 300,000 to 400,000 lb, roughly equivalent to the mass of a school

bus crashing into the ocean at 20 mph.

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y 2 0 1 5 |

i T S S e

1 1

iTSSe

|

TSS

Fig. 2

— Engineers attach the heat shield to the Orion spacecraft.