plasma gun is enabled with the use of 2000 amperage pow-

er supplies in contrast to the type of gun typically used in a

vacuum plasma spray process.

Conclusions

Vacuum plasma and low pressure plasma spray tech-

nologies each provide unique solutions for achieving supe-

rior properties in metallic coatings that require low oxide

content and high density. Applications include various tur-

bine engine components, as well as biomedical and elec-

tronics components.

For more information:

Robert Gansert is president of Ad-

vanced Materials & Technology Services Inc., 67 W. Easy St.,

Simi Valley, CA 93065, 805.581.6045,

rgansert@adv-mts.com,

www.adv-mts.com.

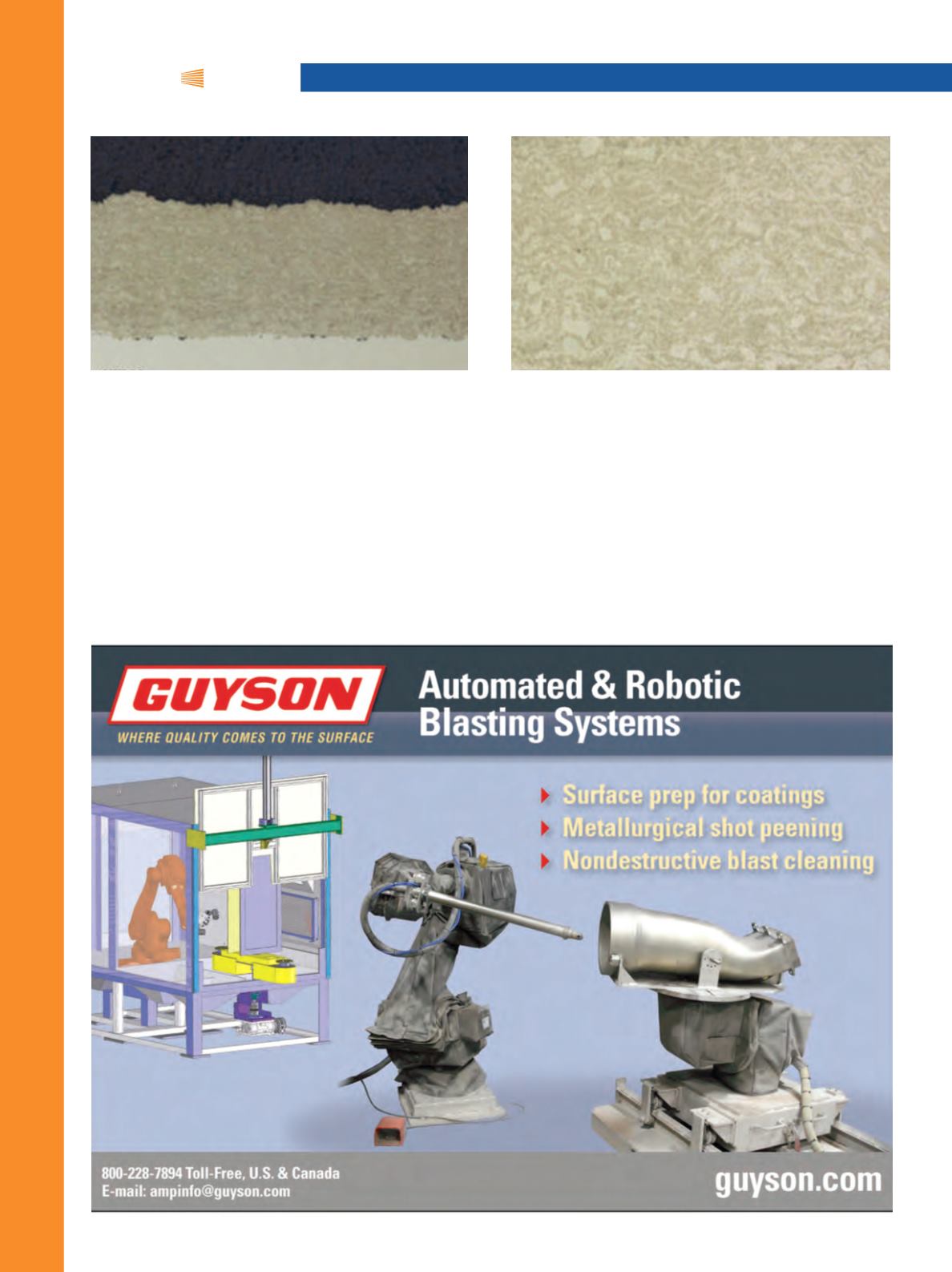

Fig. 5a

— NiCrAlY, 200x.

Fig. 5b

— NiCrAlY, 500x.

iTSSe

|

TSS

i T S S e

| a d v a n c e d m a t e r i a l s & p r o c e s s e s | F E B R U A R Y 2 0 1 5

1 0