lic lightweight (aluminum) and composite seals, RF ceramics for

microwave compatibility and absorbers, dissimilar bonded struc-

tures, and high temperature components for rocket motors.

Other potential applications include reactive fragments, war-

head parts, shaped charge liners, military ammunitions/projec-

tiles/penetrators, advanced armor, high performance magnets

(both soft and permanent magnets), heat-resistant tiles, engine

parts, leading edge components, heat shields, igniter compo-

nents, x-ray targets and tubes, and automotive/aerospace piston

rings, valve seats, and gears.

Acknowledgments:

The authors would like to thank several CDC

project sponsors from the defense, energy, and space programs

(MDA, OSD/ONR, U.S. Army-ARDEC-Picatinny, NAVY, DARPA,

and NASA), through SBIR/STTR programs and commercial indus-

tries through production programs.

For more information:

Karthik Nagarathnam is senior materials

scientist/manager, Materials Research, Utron Kinetics LLC, 9441

Innovation Dr., Manassas, VA 20110, 703.369.5552 ext. 111,

karthikn@utronkinetics.com,

utronkinetics.com.

References:

1.

ASM Metals Handbook,

Second Ed., ASM Intl., p 1-1521, 1998.

2. G.S. Upadhyaya,

Sintered Metallic and Ceramic Materials,

John

Wiley & Sons Ltd., p 1-670, 2000.

3. L.F. Pease and W.G. West,

Fundamentals of Powder Metallurgy,

MPIF Publication, ISBN 1-87895-486-5, p 1-452, 2002.

4. Utron Patent: Dynamic Consolidation of Powders Using a Pulsed

Energy Source, Patent 6,767, 505.

5. K. Nagarathnam, D. Massey, and M. Opeka, Properties of Refrac-

tory Metals and Alloys Fabricated by Combustion-Driven High-

Pressure Powder Compaction,

Int. J. Powder Metall.,

Vol 47, No. 5,

2011.

6. K. Nagarathnam, et al., Utron Kinetics, patents pending, 12, 383,

948 Near Net Shape Fabrication of High Temperature Components

Using High Pressure Combustion Driven Compaction Process; 13,

114, 716 Magnet Construction by Combustion Driven Compaction;

and 13, 195, 779 Combustion Driven Higher Pressure Near Net

Shape Powder Consolidation of Advanced High Strength Steels and

Materials Behavior.

7. K. Nagarathnam, et al., Combustion Driven Higher Pressure Pow-

der Compaction of Tantalum and Tantalum Based Refractory Ma-

terials and Properties, PowderMet 2013 Conference

Presentation/APMI Publication in

Adv. Pm. Part.,

paper 2013-01-

0169, Chicago, 2013.

ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

31

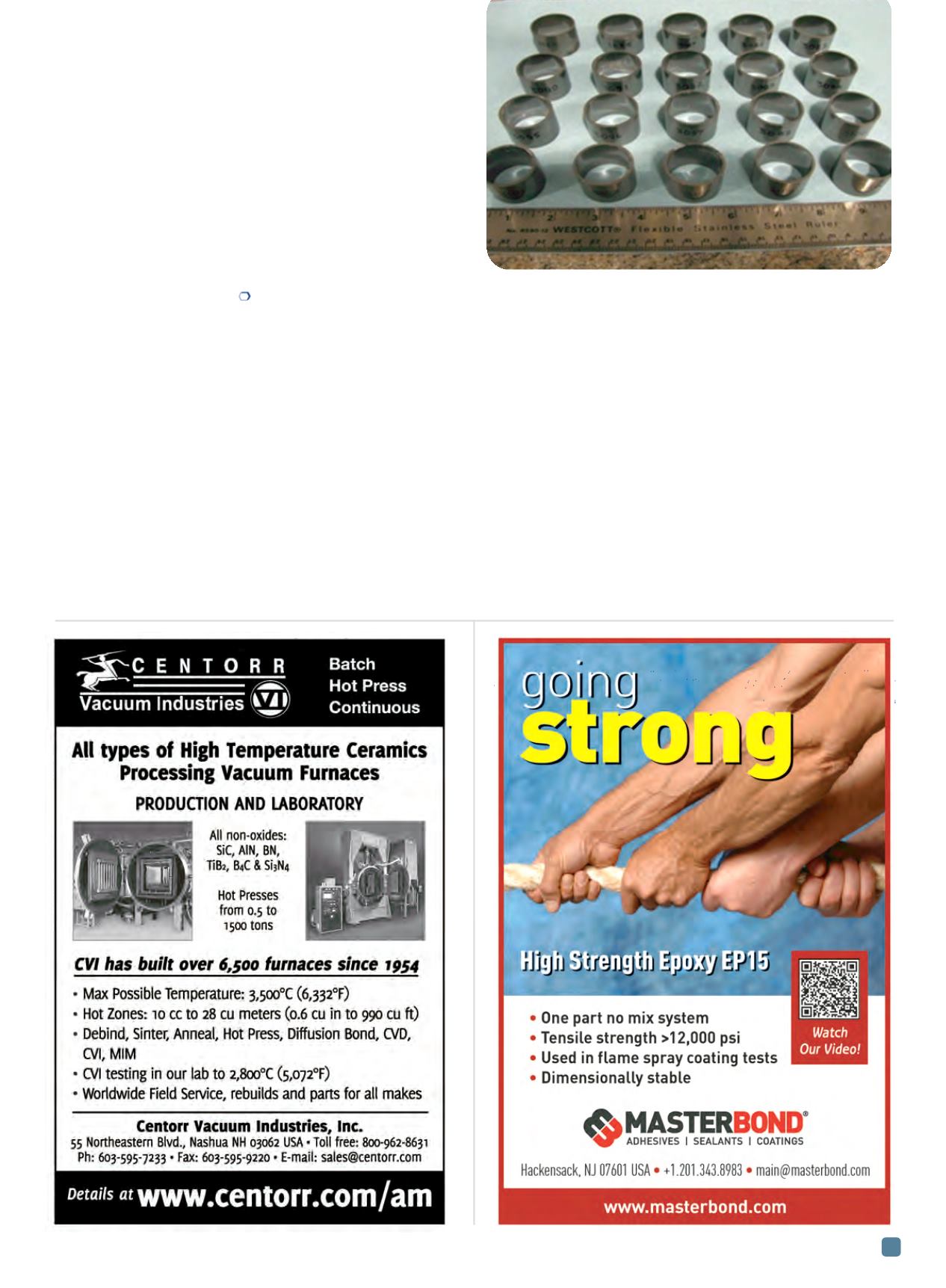

Fig. 7 —

Thin-walled (60 mil wall thickness) bonded Nd-Fe-B

magnets for automotive and other applications

[6]

.