ADVANCED MATERIALS & PROCESSES •

JUNE 2014

43

HTPRO

7

temperature rise of 5°C (10°F) with a

maximum temperature of 45°C (110°F).

For polymer quenchants, it is somewhat

more difficult. The maximum tempera-

ture for polyalkylene glycol (PAG) quen-

chants cannot exceed the cloud point

temperature. This is between 60° and

75°C (135° and 170°F) for most PAG

quenchants, depending on the molecular

weight of the polymer. It is also recom-

mended that the maximum bulk temper-

ature rise be at most 10°C (20°F) below

the cloud point temperature. Polymer

quenchants, besides being sensitive to ag-

itation, are strongly affected by tempera-

ture. The cooling rate decreases

significantly with increasing temperature.

Small temperature rises during quench-

ing reduce variations in cooling rate and

quench rate effectiveness. This also re-

duces drag-out, produces more uniform

quenching, and prolongs the life of the

quenchant. Limiting the temperature rise

greatly increases the quench tank size.

For PVP-type quenchants, there is no

cloud point temperature. However, the

maximum peak temperature is generally

limited to 65°C (150°F) or lower to pre-

vent destructive oxidation of the quen-

chant. This also reduces the amount of

drag-out and chemical consumption in

the system.

As an example, consider the design of a

quench tank containing Aqua-Quench

3699, a hybrid polymer quenchant that

does not have a cloud point. Steel parts

will be quenched from 1095° to 205°C

(2000° to 400°F), with a maximum load

weight of 2270 kg (5000 lb). The quench

tank operates at 45°C (110°F) nominally.

What volume of quenchant is required

in gallons?

To solve this, the maximum allowable

temperature rise must first be deter-

mined. For this quenchant, the maximum

temperature is 65°C (150°F). Because the

quench tank is operating at 150°F, the

temperature rise of the quenchant (Δ

T

q

)

is 40°F (i.e., 150°–110°F). From the equa-

tion above, and rearranging to determine

the mass of water required:

M

m

Cp

m

D

T

m

=

M

q

Cp

q

D

T

q

or

M

q

=

M

m

Cp

m

D

T

m

/

Cp

q

D

T

q

therefore

M

q

= 5000 lb (0.17 Btu/lb/F)

(1600)/0.95 Btu/lb/F (40F)

M

q

= 35,800 lb (16,270 kg)

polymer quenchant

A gallon of water weighs 8.33 lb/gal

(1 kg/liter), so the number of gallons re-

quired to quench 5000 lb of steel is 4296

gal (16,260 liters). Temperature rise for

polymer and oil quenchants are shown

in Figs. 1 and 2.

System temperature control

Maintaining the temperature of the

quench bath is as important as the size

of the quench tank, which requires a

means of temperature control.

Quenchant heating

is achieved using sev-

eral methods, including electrical resist-

ance heating elements, gas- and oil-fired

radiant tubes, and waste heat from the

furnace exhausts. In some systems, the

quenchant is heated by quenching a

“dummy” hot load of parts. The energy

density of radiant tubes and electrical

heating elements should not exceed 1.5

W/cm

2

(10W/in.

2

). This prevents heaters

from preferentially oxidizing the oil and

depleting the oxidation additive package.

This energy density guideline should also

be followed for polymer quenchants, with

the additional provision that maximum

heater temperature should be about 70°C

(160°F) to prevent exceeding the cloud

point of the material. Heaters should also

be interlocked with the agitation system

so they shut off if the agitation system is

shut off or fails. The system should also

be designed to make it impossible to turn

on the heating system without the agita-

tion operating.

Quenchant cooling

. Various methods are

available to cool quenchants including:

• Submerged water-cooling pipes

• Cooling jackets

• External water-cooled heat

exchangers

• Forced air-cooled radiators

• Refrigeration systems

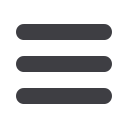

Fig. 1 —

Relationship of volume of oil quenchant and weight of quenched workload to

prevent specific temperature rise of quench bath when quenched from 1600° to 140°F

(870° to 60°C).

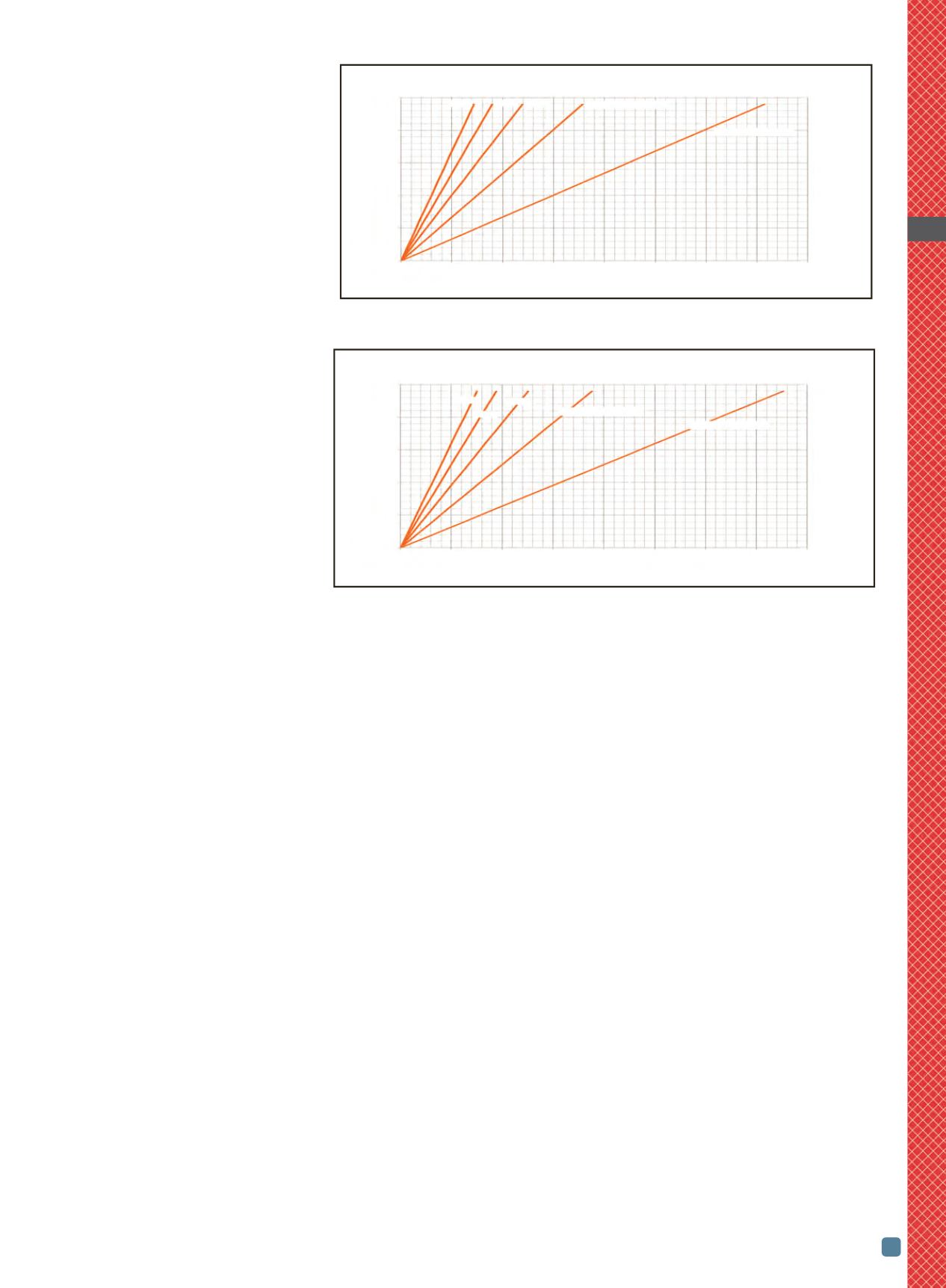

Fig. 2 —

Relationship of volume of polymer quenchant and weight of quenched workload to

prevent specific temperature rise of quench bath when quenched from 1600° to 140°F

(870° to 60°C).

2500

2000

1500

1000

500

0

2500

2000

1500

1000

500

0

Weight of batch load

quenched, lb

Weight of batch load

quenched, lb

0 1000 2000 3000 4000 5000 6000 7000 8000

Oil required in tank to limit bath temperature rise, gal

0 1000 2000 3000 4000 5000 6000 7000 8000

Polymer required in tank to limit bath temperature rise, gal

1135

910

680

455

230

0

1135

910

680

455

230

0

Oil required in tank to limit bath temperature rise, liters

0 3785 7570 11,355 15,140 18,925 22,710 26,495 30,280

Polymer required in tank to limit bath temperature rise, liters

0 3785 7570 11,355 15,140 18,925 22,710 26,495 30,280

Weight of batch load

quenched, kg

Weight of batch load

quenched, kg

100°F 80°F 60°F 40°F Temperature rise

(55°C) (45°C) (35°C) (20°C)

20°F (10°C)

50°F (25°C) 30°F (15°C)

40°F (20°C) 20°F (10°C) Temperature rise

10°F (5°C)