ADVANCED MATERIALS & PROCESSES •

JUNE 2014

47

HTPRO

11

Rotameter types

The glass or plastic rotameter (Fig. 3a),

is the most widely used because of its

low cost, low pressure drop, relatively

wide range, linear visual flow indica-

tion, and simplicity of operation. To

pass through the tapered tube, fluid

flow must raise the float. The greater

the flow rate, the higher the float is

lifted. In liquid service, the float rises

due to a combination of the liquid’s

buoyancy and its velocity. With gases,

buoyancy is negligible, so the float re-

sponds mostly to velocity.

The float moves up and down in pro-

portion to the fluid flow rate and the

annular area between the float and the

tube wall. As the float rises, the size of

the annular opening increases. As the

area increases, the differential pressure

across the float decreases. The float

reaches a stable position when the up-

ward force exerted by the flowing fluid

equals the weight of the float. Thus,

every float position corresponds to a

specific flow rate for a particular fluid’s

density and viscosity.

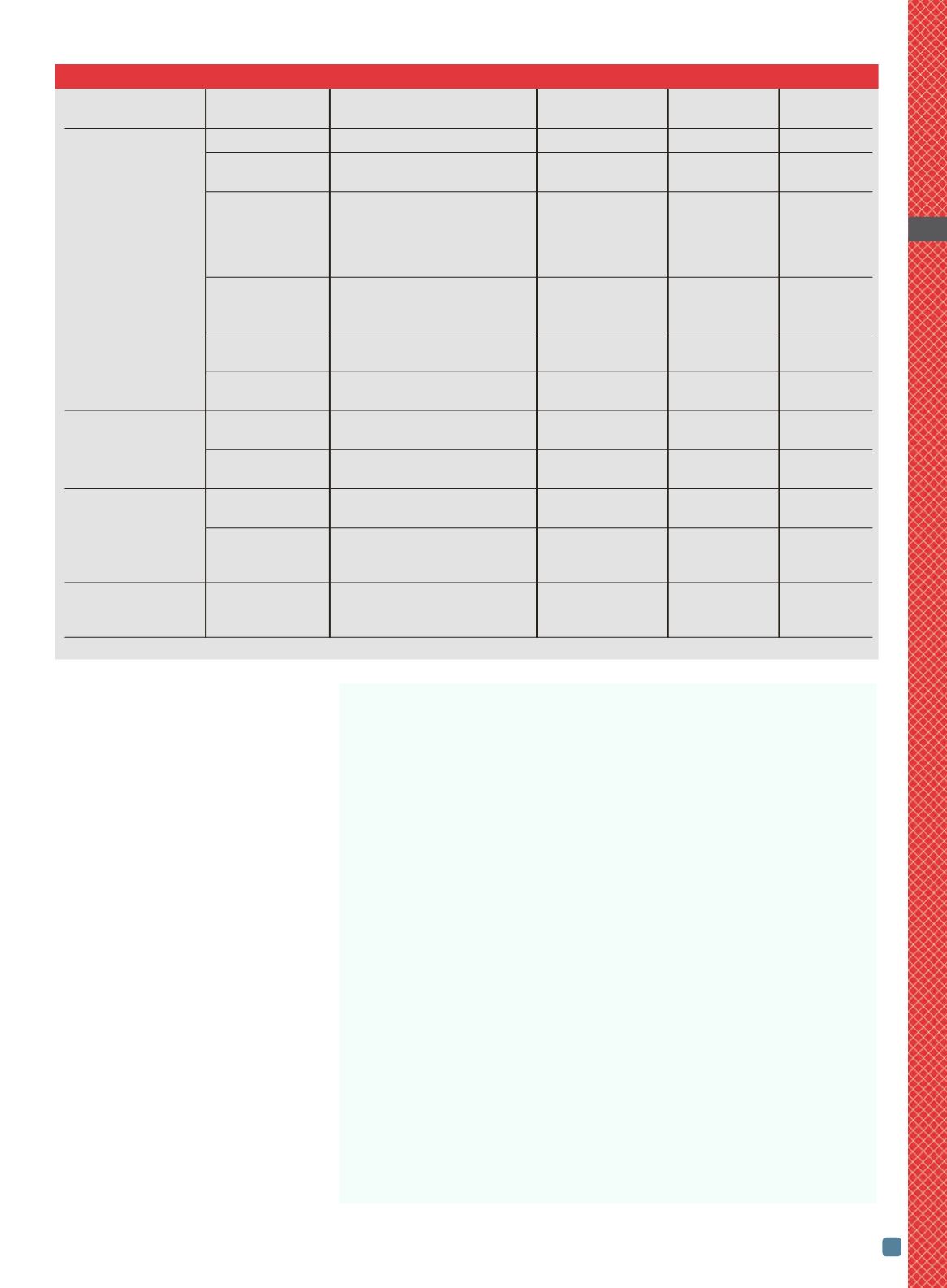

TABLE 1 — COMMONLY USED FLOW MEASUREMENT INSTRUMENTS BY TYPE

Industrial

Disassembly

Sensitivity to

Robust

flowmeter type

Style

Manufacturer (a)

without repiping dirty fluids spare parts

Variable area,

Metal tube

Waukee Engineering Co. Inc.

Yes

Moderate

Delicate

including rotameters

Metal cylinder

Meter Equipment Mfg. Inc.

Yes

Low

Moderate

tube

Glass or plastic

Fisher-Porter

No

Sensitive

Moderate

tube

Brooks Instrument

King Instrument Co.

Dwyer Instruments Inc.

Key Instruments

Vane type

Universal Flow Monitors Inc.

No

Moderate

Moderate

Erdco Engineering Corp.

Orange Research Inc.

Moving orifice

Hedland, Div.

No

Moderate

Robust

Racine Federated Inc.

Piston

Insite (Universal Flow

No

Moderate

Delicate

(with spring)

Monitors Inc.)

Differential pressure/

Orifice

Lambda Square Inc.

No

Moderate

Robust

Orifice

Flowell Corp.

Venturi

Flowell Corp.

No

Moderate

Robust

Fox Valve Development Corp.

Turbine/Impeller

Rotary impeller

Roots (BNC Industrial Co. Ltd.)

No

Sensitive

Moderate

TokicoTechno Ltd.

Turbine

Hoffer Flow Controls Inc.

No

Sensitive

Delicate

Sponsler Inc.

Great Plains Industries Inc.

Thermal mass

Thermal mass

Sierra Instruments Inc.

No

Sensitive

Delicate

MKS Instruments

Brooks Instrument

(a) Not all-inclusive

Features and advantages

Advantages of variable-area flowmeters include:

• Mechanical flow measurement with just a single moving part,

ensuring measurement reliability

• Application versatility and availability of a variety of construction

materials, inlet and outlet sizes, and types

• Easy installation with generally no straight pipe requirements

• Low pressure drops

• Linear scales, allowing easy flow measurement interpretation

• Electronic output availability, preserving the mechanical flow

measurement

Advantages of tapered-tube rotameters include:

• Low instrument cost (when glass or plastic metering tube is used)

• Can be used for very low flow rates

Advantages of slotted-cylinder flowmeters include:

• Flow measurement accuracy determined by the precision of the slot

manufacturing operation; good flow range of 25:1 results

• Instrument specifications can be changed by field replacement of the

slotted tube and float without having to re-pipe the flowmeter vessel

• Ability to handle high flows and pressures

• Improved immunity to pulsating flows, with no minimum backpressure

Limitations common to both tapered-tube and slotted-cylinder variable-area

flowmeters include the requirement of vertical mounting aand the fact that they

contain moving parts.