with DCPD, potential drop is measured continuously or

periodically from the specimen, so a real-time crack size

measurement is available. The

J-Integral

calculation is

performed in the same manner as EUC or normalization

to yield the J-R curve.

Once the original J-R curve from DCPD is ob-

tained, adjustments are needed to differentiate po-

tential drop due to stable crack growth from material

deformation

[7, 13]

. Although difficulties still exist in

adjusting DCPD data to yield valid J-R curve results,

new methodology

[14]

shows improved results over

previous DCPD adjustment methods

[15]

with prom-

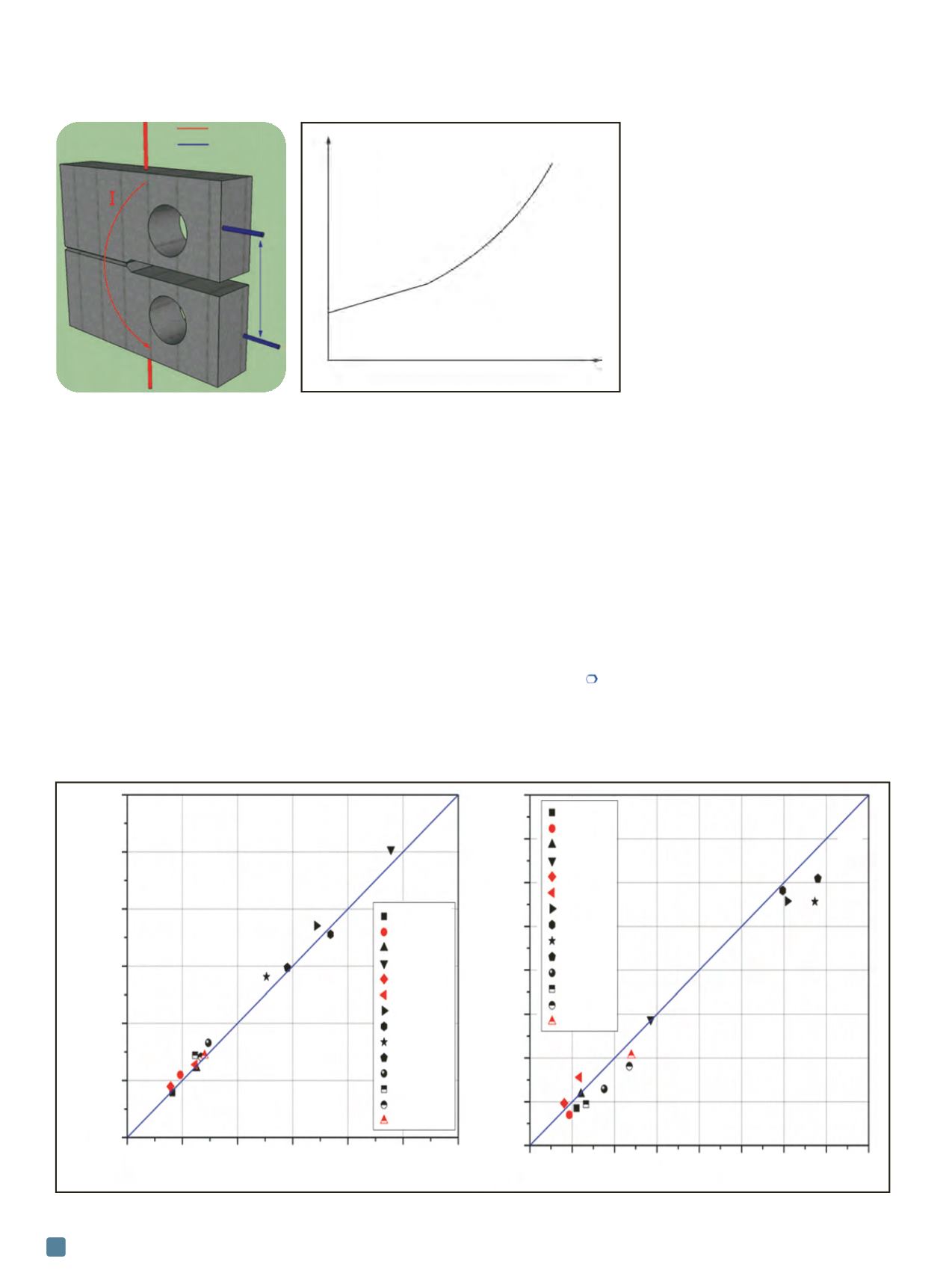

ising J-R curve results. As shown in Fig. 8, after in-

corporating the new adjustment procedure, ductile

fracture toughness near the initiation of stable crack

growth ( Jq) from DCPD is in excellent agreement

with results from EUC and normalization, whereas

only small deviations are observed

in tearing modulus (T R ) results.

Summary

This article presents the experi-

mental setup and three different

techniques—EUC, normalization,

and DCPD—for evaluating ductile

fracture toughness in metals using

the J-R curve. The

J-Integral

calcula-

tion is the same in all three methods,

with differences primarily involving

crack size measurements. EUC relies

on material compliance to derive the

real-time crack size, while for the

normalization method, initial and

final crack lengths are measured and

intermediate crack sizes are determined based on the

normalization function. For DCPD, the correlation be-

tween potential drop and crack size is exploited to as-

sess crack size. All three methods are applicable for

testing in the normal temperature range. However, for

elevated temperature tests, the material relaxation be-

havior and increased friction between the loading cle-

vises and pins degrade the accuracy of the elastic

compliance measurements for the EUC method, so

normalization or DCPD should be used. In addition,

the original J-R curve based on DCPD requires adjust-

ment to account for the deformation-induced poten-

tial drop.

Acknowledgment

The authors are grateful to Chunghao Shih for his technical

review of this article.

ADVANCED MATERIALS & PROCESSES •

APRIL 2014

22

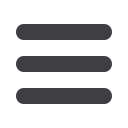

Fig. 7 —

Schematic for (a) direct current potential drop measurement and

(b) crack-growth-induced increase in potential drop.

Fig. 8

—

Comparison of post-adjustment DCPD J-R curve results with EUC (black symbols) or normalization (red symbols)

[14]

.

Current probe

Potential probe

U

(a) (b)

Potential drop U

Crack length a

y=x

y=x

0 200 400 600 800

1000 1200

Compliance or Normalization Jq

(kJ/m

2

)

1200

1000

800

600

400

200

0

DCPD Jq (kJ/m

2

)

0 100 200 300 400 500 600 700 800

Compliance or Normalization tearing modulus

800

700

600

500

400

300

200

100

0

DCPD tearing modulus

MatA 150

o

C

MatA 371

o

C

MatA 421

o

C

MatB 371

o

C

MatB 538

o

C

MatB 593

o

C

MatC 24

o

C

MatC 100

o

C

MatC 250

o

C

MatC 500

o

C

MatD 24

o

C

MatD 400

o

C

MatD 500

o

C

MatD 600

o

C

MatA 150

o

C

MatA 371

o

C

MatA 421

o

C

MatB 371

o

C

MatB 538

o

C

MatB 593

o

C

MatC 24

o

C

MatC 100

o

C

MatC 250

o

C

MatC 500

o

C

MatD 24

o

C

MatD 400

o

C

MatD 500

o

C

MatD 600

o

C