displacement of the SE(B) specimen is measured from the

displacement of the specimen notch root by a LVDT sen-

sor. Alternatively, the CMOD of the SE(B) specimen is

measured by a displacement gage. For both C(T) and

SE(B) specimens, a load cell (not shown in Figs. 3 and 4)

measures specimen load.

Elastic unloading compliance (EUC)

Because a J-R curve consists of two parts,

J-Integral

and

crack growth, determining this curve naturally involves

calculating both aspects. In

elastic unloading compliance

(EUC), the

J-Integral

is calculated as:

(1)

where

J

el(i)

and

J

pl(i)

are the elastic and plastic components

of

J-Integral

, respectively. For

J

el(i)

:

(2)

where

ν

is Poisson’s ratio,

E

is Young’s modulus, and

K

(i)

is

the stress intensity factor.

K

(i)

depends on specimen config-

uration, load level, crack size, and other factors. The equa-

tion for calculating

J

pl(i)

follows:

(3)

where

a

(i)

is the current crack size,

b

(i)

is the unbroken lig-

ament size,

B

N

is the specimen net thickness,

A

pl(i)

is the

plastic area under the load versus load-line displacement

record for the specimen,

η

pl(i-1)

equals 1.9 for a SE(B) spec-

imen and (2+0.522b

(i-1)

/W) for a C(T) or DC(T) specimen,

and

γ

equals 0.9 for a SE(B) specimen and (1+0.76b

(i-1)

/W)

for a C(T) or DC(T) specimen. In order to obtain the real-

time crack growth value, EUC measures the material com-

pliance (the ratio of displacement increment to force

increment) by periodic unloading and reloading of the

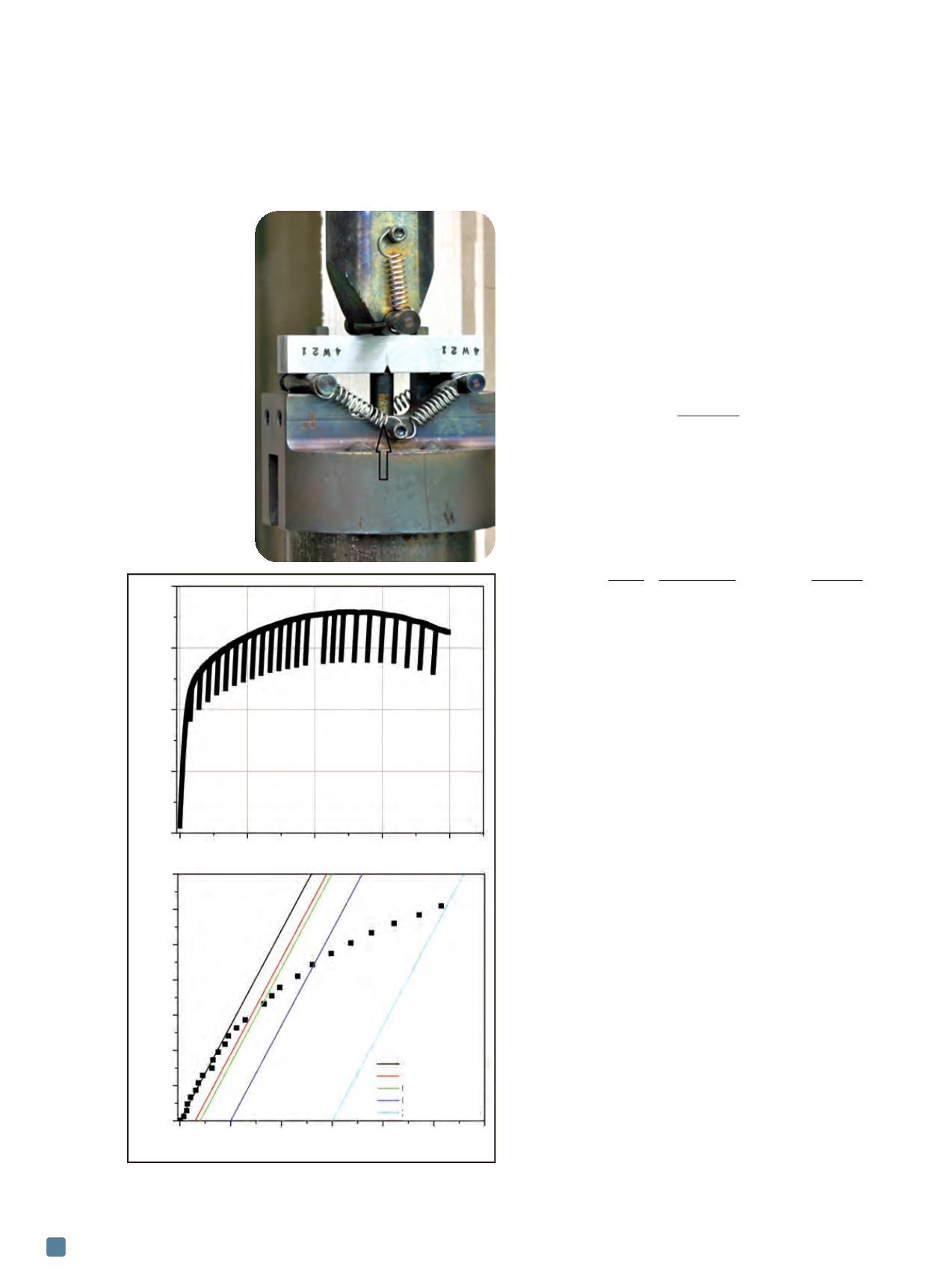

specimen. For instance, a typical load-displacement record

for a J-R curve test using EUC is shown in Fig. 5(a). Each

short straight line in Fig. 5(a) represents an unloading-re-

loading sequence. The rest of the curve resembles a load-

displacement curve in a tensile test, i.e., initial elastic

deformation followed by plastic deformation and load drop

after passing the maximum load level. Once the material

compliance value is obtained, equations in ASTM standard

E1820-11

[1]

can be applied to convert the compliance re-

sult to the estimated real-time crack size. Eventually, com-

bining the

J-Integral

and crack growth results yields the J-R

data as shown in Fig. 5(b).

Since its introduction, the EUC method has gained

wide popularity for the J-R curve test. However, EUC still

faces considerable challenges for testing in extreme envi-

ronments. For example, in elevated temperature testing

(above 500°C), the compliance measurement in EUC is af-

fected by the material relaxation behavior and increased

friction between loading clevises and pins, which results

in unreliable crack size measurement. In addition, EUC is

relatively time-consuming due to the periodic unloading-

ADVANCED MATERIALS & PROCESSES •

APRIL 2014

20

Fig. 5 —

(a) Load-displacement record for a J-R curve test with

elastic unloading compliance (EUC); (b) J-R data determined

by EUC.

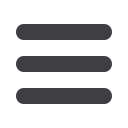

Fig. 4 —

Apparatus for the

J-R curve test of a

single edge bend

specimen.

J

(i)

= J

el(i)

+ J

pl(i)

K

(i)

2

(1- v

2

)

E

J

el(i)

=

J

pl(i)

=

[

J

pl(i-1)

+

x ] x [1-

γ

pl(i-1)

]

η

pl(i-1)

A

pl(i)

-

A

pl(i-1)

a

(i)

-

a

(i-1)

b

(i-1)

B

N

b

(i-1)

LVDT

0

2

4

6

8

Displacement (mm)

(a)

(b)

16

12

8

4

0

Load (kN)

Construction line

1stexclusion line

0.2mmoffset line

0.5mmoffset line

2ndexclusion line

0.0 0.5 1.0

1.5

2.0

2.5 3.0

D

a (mm)

1400

1200

1000

800

600

400

200

0

J-Integral

(kJ/m

2

)