news

industry

Protecting troops with nanoceramics

The U.S. Army Research Laboratory dedicated a 5-year program to advanced metals

and ceramics for armor and anti-armor applications. To provide greater protection against

blunt trauma and higher velocity ammunition than can be provided by a standalone soft

ballistic vest, hard body armor was developed. It includes a rigid facing comprising ce-

ramic inserts, steel or titanium panels, and a ballistic fabric backing.

In hard armor with ce-

ramic inserts, the projectile’s

kinetic energy is absorbed

and dissipated in localized

shattering of the ceramic tile

and blunting of the bullet ma-

terial during impact. Armor

ceramics are critical for

weight reduction in current

and future military and civil-

ian applications. Realizing the

full potential of armor ceram-

ics requires an understanding of how the structure of armor-ceramic materials, at several

length scales, affects the inherent ballistic performance and its variability among identical

components.

Carbon nanotubes (CNTs) are being considered as a reinforcing material to enhance

the mechanical properties of ceramics, particularly fracture toughness, which is likely to

improve their resistance against multiple bullets. Recent studies show that CNTs in ce-

ramics like alumina and silicon carbide can have a strong influence on microstructure,

fracture mode, and mechanical properties. An improvement of up to 94% in fracture

toughness was observed when 4 vol.% of CNTs are added to alumina.

www.arl.army.mil.

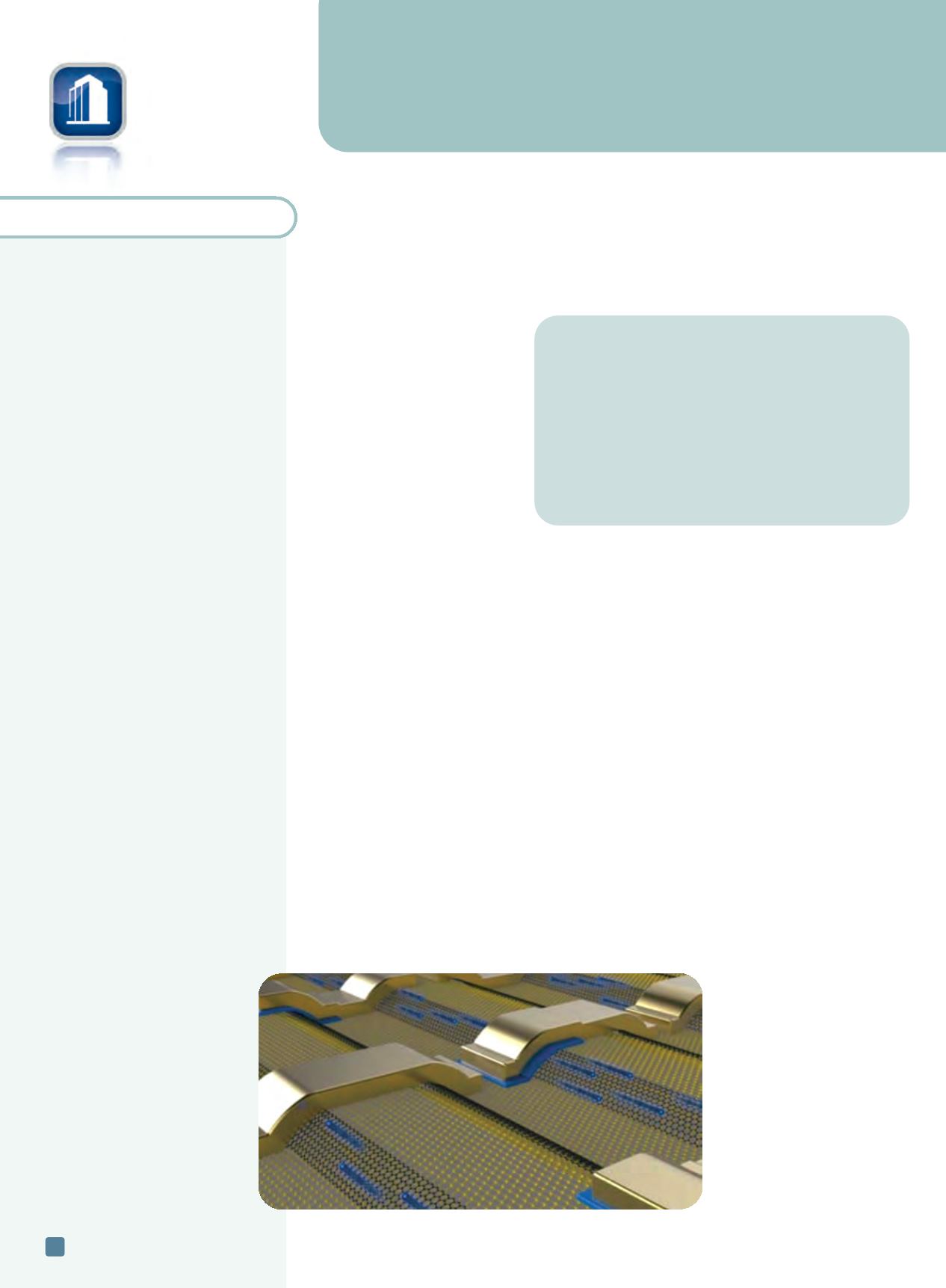

Graphene ribbons highly conductive at room temperature

An international team including researchers from the French National Centre for Sci-

entific Research (CNRS), Université de Lorraine, the SOLEIL synchrotron facility, all in

France, Georgia Institute of Technology, Atlanta, Oak Ridge National Laboratory, Tenn.,

and Université de Leibniz, Germany, produced graphene ribbons in which electrons move

freely. The team devised a novel way of synthesizing such ribbons, and demonstrated their

exceptional electrical conductivity at room temperature. The nanoribbons hold great

promise for next-generation electronics, say researchers.

The team synthesized 1D graphene from silicon carbide and was able to obtain

graphene ribbons of very high structural quality, made of an extremely narrow sheet of

carbon only 40 nm wide. In order to obtain ribbons with regular edges, nanometer-deep

steps were etched into the silicon carbide, producing graphene ribbons directly on the

sidewalls of the steps.

www.gatech.edu.

ADVANCED MATERIALS & PROCESSES •

APRIL 2014

18

N

ANOTECHNOLOGY

briefs

Researchers at

Seoul National

University,

Korea, found that

nanoscale 3D objects such as

freestanding nanowalls can be

constructed using additive

manufacturing. Even without the

motion of the substrate, nanojets

are spontaneously laid down and

piled to yield nanowalls. A thin

metal line on an insulating plate

focuses the electrical field,

suppressing the instability of the

electrical nanojets. To stack fibers

in a controlled fashion, the fiber

deposit is manipulated to attract

rather than repel the incoming

nanojets by quickly draining the

electrical charge. A nanowall that

lines the ground is formed, which

implies that various freestanding

structures can be created in a

desired shape.

www.useoul.edu.

Stephen Goodnick, professor at

Arizona State University,

Phoenix,

gave a talk on nanoelectronics

advances that could increase

performance of solar energy

systems at the 2014 annual

meeting of the

American

Association for the

Advancement of Science (AAAS),

Chicago, in February. Innovations

driven by nanoelectronics research

enable photovoltaic technology to

significantly improve the ability to

convert sunlight and heat into

electric power. New types of

nanostructure-based devices can

facilitate production of photovoltaic

solar cells that achieve better

energy-conversion efficiency.

Stephen Goodnick, 480/965-9572,

stephen.goodnick@asu.edu,

www.asu.edu/aine/index.htm.Conceptual drawing of an

electronic circuit comprised

of interconnected graphene

nanoribbons (black atoms)

that are epitaxially grown

on steps etched in silicon

carbide (yellow atoms).

Electrons (blue) travel

ballistically along the ribbon

and then from one ribbon

to the next via the metal

contacts. Electron flow is

modulated by electrostatic

gates. Courtesy of John

Hankinson/Georgia Institute

of Technology.

Researchers at

Karlsruhe Institute of Technology,

Germany, and

Carnegie Mellon University,

Pittsburgh, developed the first ad-

hesive tape that not only adheres to a surface as reliably as the

toes of a gecko, but also has similar self-cleaning properties. Elas-

tic microhairs of variable size were used and, instead of dirt parti-

cles, micrometer-sized glass spheres were distributed on a smooth

plate. An artificial adhesive tape covered by microhairs was

pressed onto the plate, shifted, and lifted off. When the diameter of

the spheres exceeded that of the microhairs, the adhesive force

disappeared after the first contact. After eight to 10 test cycles,

however, the gecko-inspired adhesive tape reached 80 to 100% of

its original power again.

www.kit.edu/english,

www.cmu.edu.