news

industry

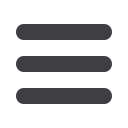

Growing hairy materials at the microscale

Scientists at the DOE’s Argonne National

Laboratory, Ill., attacked a tangled problem

by developing a new technique to grow tiny

“hairy” materials that assemble themselves at

the microscale. Epoxy is the key ingredient

and it is added to a mixture of hardener and

solvent inside an electric cell. An alternating

current is run through the cell while long,

twisting fibers spring up—similar to the way

Chia Pets grow.

“The process is very simple, the materi-

als are inexpensive and available, and they

can grow on almost every surface we’ve

tried,” explains physicist Igor Aronson. By

tweaking the process, many different shapes

can be grown—short forests of dense straight

hairs, long branching strands, or “mush-

rooms” with tiny pearls at the tips. Although

the structures can be permanent, the process is also instantly reversible.

www.anl.gov.Gummy material prevents fires in lithium batteries

Researchers fromWashington State University, Pullman, developed a chewing gum-like

battery material that could dramatically improve the safety of lithium ion batteries. The

biggest risk comes from the battery’s electrolyte, which is made from either a liquid or gel.

These acidic liquid solutions can leak, potentially causing fires or chemical burns.

Professor Katie Zhong’s research group developed a gum-like lithium battery elec-

trolyte, which conducts electricity as well as liquid versions, but does not create a fire haz-

ard. The material—a liquid-solid hybrid—contains liquid electrolyte material that hangs on

solid particles of wax or a similar material. Current can easily travel through the liquid

parts of the electrolyte while solid particles provide protection. If the material gets too hot,

the solid melts and stops conduction, preventing fire hazards. The electrolyte material is

flexible and lightweight, and can be stretched, smashed, and twisted.

For more information:

Katie Zhong, 509/335-7658,

katie_zhong@wsu.edu,

www.wsu.edu.

Flat-pack lens boosts solar power

Researchers at the State Key Laboratory of Precision Measuring Technology & Instru-

ments, Tianjin University, China, are able to craft the surface structures on a Fresnel lens

with an array of microscopic cones (rather than concentric ridges), bringing incident light

to a point at a more precise depth on the photoactive layer in solar panels.

Initial tests with their precision-machined Fresnel solar collector showed a peak power

four times higher than standard panels at low resistance. The difference in power falls off

quickly as the device’s resistance rises, which it

does as it gets hotter under sunlight and as a

byproduct of generating electricity. Nevertheless,

the differential would be enough to boost its elec-

trical output, substantially offsetting the addi-

tional cost of the Fresnel collector so that the

overall cost of solar panels might be reduced. This

simple addition to older, less efficient solar panels

might also make them viable for places and appli-

cations where modern devices of higher intrinsic

efficiency are not commercially tenable.

www.tju.edu.cn/english/Research/Facilities.ADVANCED MATERIALS & PROCESSES •

APRIL 2014

14

E

NERGY

T

RENDS

briefs

The

DOE

recently announced that

the U.S. solar industry is more than

60% of the way to achieving cost-

competitive, utility-scale solar

photovoltaic (PV) electricity—only

three years into the Department’s

decade-long SunShot Initiative. To

facilitate further progress, $25

million in funding will help

strengthen U.S. solar

manufacturing for PV and

concentrating solar power

technologies and maintain a strong

domestic solar industry—

supporting the broader Clean

Energy Manufacturing Initiative.

www.energy.gov.Plastic shopping bags, an

abundant source of litter on land

and at sea, can be converted into

diesel, natural gas, and other

useful petroleum products,

according to researchers at the

Illinois Sustainable Technology

Center at the University of

Illinois,

Champaign. The

conversion produces significantly

more energy than it requires and

results in transportation fuels—

diesel, for example—that can be

blended with existing ultra-low-

sulfur diesels and biodiesels. Other

products, such as natural gas,

naphtha (a solvent), gasoline,

waxes, and lubricating oils such as

engine oil and hydraulic oil also

can be obtained from shopping

bags.

www.istc.illinois.edu.

Used plastic shopping bags can

be converted into petroleum

products that serve a multitude

of purposes. Courtesy of Julie

McMahon.

These tiny “mushrooms” could be useful in

new energy technologies. The scale bar

shows 20 µm, about the size of a single

bacterium. Courtesy of Alexey Snezhko and

Igor Aronson/Argonne National Laboratory.

Researchers at the

Helmholtz Center Berlin

(HZB), Germany, demonstrated that tiny voids

within the silicon network are partly respon-

sible for reducing solar cell efficiency by

roughly 10 to 15% as soon as use begins.

Defects in amorphous silicon come in two

types: Those that are uniformly distributed

and those that are concentrated in clusters

on internal surfaces of small voids—known

as microvoids—which form within the ma-

terial during solar cell manufacturing.

www.helmholtz-berlin.de/index_en.html.