2014 is International Year of Crystallography

One hundred years ago,

x-rays were used for the first time

to determine the crystal structure

of materials. The pioneering work

of Max von Laue, for which he

won the Nobel Prize in physics,

was followed by a joint award in

1915 (also in physics) to father and

son Sir William Henry Bragg and

William Lawrence Bragg. Since

then, more than 25 Nobel Prizes

were awarded in areas related to x-

ray diffraction, such as crystallog-

raphy, electron microscopy, and

topics related to the structure of

matter and its properties.

The United Nations pro-

claimed 2014 to be the Interna-

tional Year of Crystallography as

a way to commemorate not only

the achievements of von Laue and

the Braggs, but also to mark the 400th anniversary of Johannes Kepler’s observation of

symmetry in ice crystals, which sparked wider study of the role of symmetry in matter.

The discovery of x-rays in the late 19th century transformed the field of crystallogra-

phy, which previously relied on classifying crystals based on morphological appearance.

The interaction of x-rays with crystals showed that x-rays are electromagnetic waves with

a wavelength of about 10

-10

m, and that the internal structure of crystals was spatially pe-

riodic over long distances. Since then, crystallography has become a basic discipline of

many branches of physical and biological sciences, including materials science and metal-

lurgy. Understanding the role of defects in crystal lattices and how they affect the deforma-

tion of metals has revolutionized the design of materials for the infrastructure of the

industrialized world.

www.iycr2014.org,

www.llnl.gov.WPI leads project to design lightweight metals for military vehicles

Worcester Polytechnic Institute (WPI), Mass., is the lead institution on a $7.4 million,

multi-university award from the U.S. Army to support development of new metallurgical

methods and lightweight alloys to help build more effective and durable military vehicles

and systems. WPI will receive $2.1 million through the two-year award to develop data-

bases and computer modeling techniques that make it possible to predict nanoscale prop-

erties of lightweight alloys (primarily aluminum, titanium, and magnesium), and to use

these computational tools to design and test new alloys for specific military applications.

“The military wants new alloys that are strong enough to be used structurally, tough

enough to function as armor, and light enough to improve the mobility and fuel economy

of vehicles,” says Richard Sisson, director of WPI’s Materials Science and Engineering Pro-

gram and principal investigator for the Army award.

Sisson is working with co-principal investigators Diran Apelian, director of the Metal

Processing Institute (MPI), and Makhlouf Makhlouf, director of the MPI’s Aluminum Cast-

ing Research Center. They are using a variety of modeling techniques, including thermo-

dynamic and kinetic models plus laboratory studies, to predict the microstructure and

microchemistry of new alloys. A variety of metallurgical processes, including heat treating,

are also being studied. From this work, modelling tools that can be used to improve exist-

ing alloys or design new alloys with the desired properties are being derived.

The award also includes a focus on high-strength magnesium alloys used by the mili-

briefs

FEI Co.,

Hillsboro, Ore., installed a

suite of high-end electron

microscopes at

Simon Fraser

University’s (SFU) Centre for Soft

Materials,

Vancouver, B.C.

Systems include the Tecnai Osiris

transmission electron microscope

and Helios DualBeam scanning

electron microscope/focused ion

beam. The systems join several

other FEI microscopes in the 4D

LABS facility where the new

multimillion dollar center is

housed.

www.fei.com,

www.sfu.ca.

Scientists use the Helios

NanoLab DualBeam at Simon

Fraser University.

JEOL USA Inc.,

Peabody, Mass.,

launched an image contest to

showcase some of the best work

of its electron microscope users. A

winning entry is being selected

each month this year, judged by

JEOL’s SEM and TEM applications

teams for both technical and

artistic qualities. All submissions

are part of an online gallery with a

description of the sample and

technique used. The first winner—

Nano Bling—was submitted by

Colin Davis of

Rocky Mountain

Laboratories

in Golden, Colo. The

image, taken with an older model

field emission SEM installed in the

1990s, was chosen for its

contrasting textures and

amorphous threads leading to an

ordered sharply

angular crystal.

www.jeolusa.com.

Nano Bling.

Courtesy of

Rocky Mountain

Laboratories.

ADVANCED MATERIALS & PROCESSES •

APRIL 2014

10

T

ESTING

C

HARACTERIZATION

news

industry

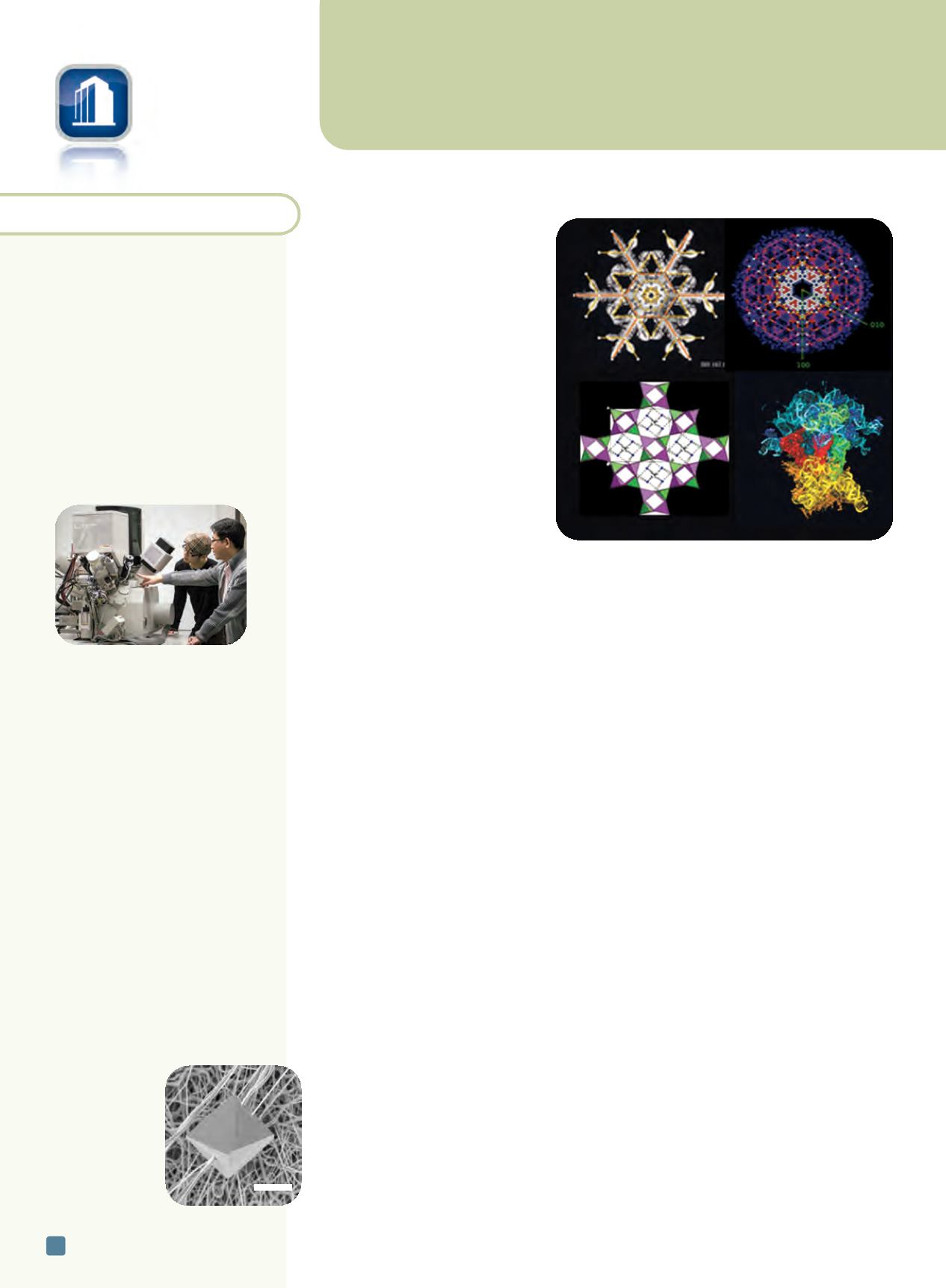

From left, clockwise, crystal structures of a snowflake,

free electron laser, zeolite, and ribosome. Courtesy of the

International Union of Crystallography.

5

m

m