Using additives to decrease vehicle weight

Milliken, Ghent, Belgium, developed an innovative and high performance reinforcing

agent, Hyperform HPR-803i and Hyperform HPN nucleating additives

for polyolefins. Hyperform HPR-803i enables automotive design-

ers to create parts that are up to 15% lighter without

compromising performance. It is added at a lower

rate than mineral fillers to polypropylene (PP) com-

pounds, to lower their density. HyperformHPR-803i

compounds are suitable for injection molding oper-

ations originally designed for talc-filled compounds,

simplifying testing requirements and reducing imple-

mentation costs. PP compounds reinforced with HPR-803i main-

tain their mechanical properties even after multiple recycling and compounding

operations. Part surface appearance can also be improved, and HPR-803i lets processors

reduce pigment usage while still meeting color requirements. Scratch appearance is im-

proved, which allows for further optimization.

www.millikenchemical.com.

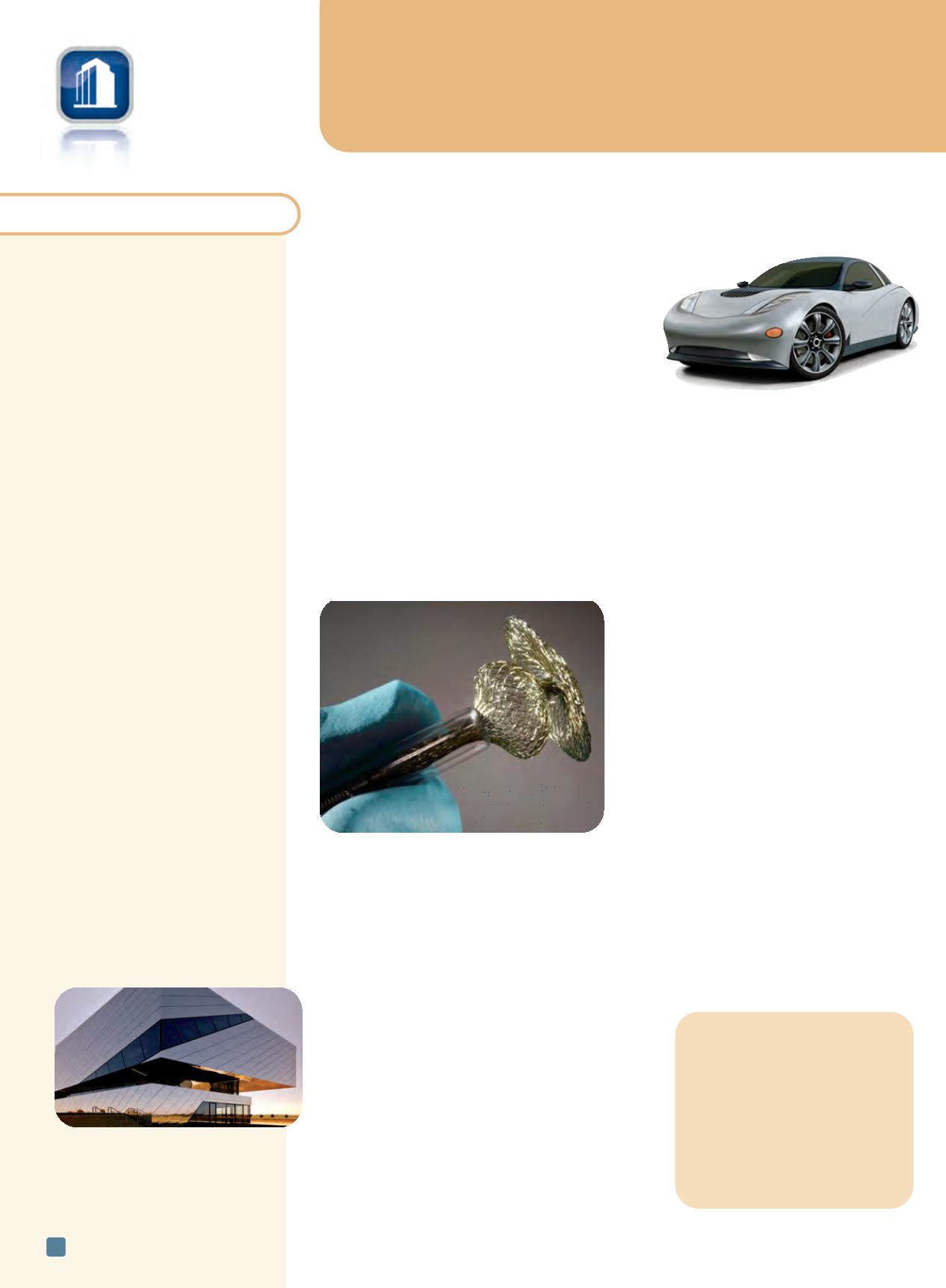

Nickel implants pose no health threat

Nickel-titanium alloys are increasingly used for cardiovascular implants in minimally in-

vasive surgery. Once implanted, these alloys can release small amounts of nickel due to cor-

rosion. There is a concern that, over time, this could lead to nickel contamination in the

patient’s body, potentially causing health

problems. However, scientists at Friedrich

Schiller University Jena, Germany, found

that the release of nickel from wires made

of nickel-titanium alloys is very low and

decreases over longer periods.

Fine wires from a superelastic nickel-

titanium alloy applied in the form of oc-

cluders (medical implants used to

correct a defective cardiac septum) were

examined. Wire samples, which under-

went different mechanical and thermal

pretreatment, were exposed to highly

purified water and the nickel release

over predefined time intervals was ex-

amined. Depending on the material’s pretreatment, considerable amounts of nickel may

be released due to the mechanical strain of the implant during surgery for the first few

days or weeks after. “In the long run, however, the nickel release decreases to amounts

of a few nanograms per day and is hence far below the amount of nickel that we absorb

anyway through our food on a daily basis,” says Prof. Andreas Unidisz.

For more informa-

tion: Andreas Undisz, 49 3641-947768,

andreas.undisz@uni-jena.de,

www.uni-jena.de.

Electronics in extreme environments

Ionix Advanced Technologies Ltd., a spin-out

company from the University of Leeds, UK, re-

ceived funding from IP Group plc. to accelerate

commercialization of devices based on high-tem-

perature piezoelectric materials developed by the

university. Piezoelectric technology, which converts

environmental physical forces into electricity, is

used in everything from sonar to industrial sensors

to ultrasound scans in pregnancy. The new materi-

als work in extreme conditions such as high tem-

news

industry

briefs

IBC Advanced Alloys Corp.,

Vancouver, signed a nonbinding

memorandum of understanding

(MOU) with

Nu-Cast Inc.,

Londonderry, N.H., to collaborate

on new beryllium-aluminum

investment casting projects and

opportunities, initially for the

aerospace sector. The MOU

outlines a framework for

increasing manufacturing capacity

and improving production

efficiencies of IBC’s proprietary

near-net-shape beryllium-

aluminum castings. The parties will

also focus on joint business

development initiatives aimed at

increasing market share for IBC’s

castings, which offer significant

cost savings and improved delivery

times compared to existing

production methods.

www.ibcadvancedalloys.com,

www.nu-cast.com.

The new

Paläon Schöningen

research and experience center,

Germany, has a reflecting facade

that mirrors the surrounding

countryside.

ThyssenKrupp

Plastics

supplied roughly 4500 m

2

of ALUCOBOND panels with a

special mirror finish for the

building, which opened in June

2013. Panels were installed using

a special adhesive and rivet

technique to make the skin of the

Paläon appear like an oversize

mirror. ALUCOBOND is a strong yet

flexible material consisting of two

aluminum face sheets and a

polymer core. It is extremely

weatherproof, impact resistant,

and vibration damping.

www.thyssenkrupp.com.

The unusual design of the

Paläon with ALUCOBOND

panels won the 2013 German

Facade Award for rainscreen

cladding.

M

ETALS

P

OLYMERS

C

ERAMICS

ADVANCED MATERIALS & PROCESSES •

APRIL 2014

8

An occluder made of a nickel-titanium alloy

used to correct a defective cardiac septum.

Quanex Building Products Corp.,

Hous-

ton, signed a purchase agreement to sell

its interest in

Nichols Aluminum LLC,

a

wholly owned subsidiary, to

Aleris,

Beachwood, Ohio, for $110 million in a

cash transaction subject to customary

regulatory approvals. Nichols has a long

history of producing flat-rolled alu-

minum sheet products for a number of

key industries across North America.

www.quanex.com.