A

new report from SPI, the plastics industry trade association, pres-

ents a detailed overview of the state of the U.S. plastics industry.

Size

and Impact of the Plastics Industry on the U.S. Economy,

published No-

vember 2013, notes that this industry has been one of the economy’s

largest and fastest growing. Although hit hard by the 2008-2009 reces-

sion, it is now recovering. Most plastics are used in manufacturing and

services are becoming increasingly important. Lower inflation, dollar

value reduction, and lower natural gas prices have spurred U.S. exports,

moderating the recession effects. Those same advantages should help the

plastics industry in the future, according to analysts. Mirroring numerous

other industries, a shrinking number of businesses indicate a continuing

consolidation trend. Key findings of the newly released report include:

The U.S. plastics industry is large, accounting for 892,000 jobs and

$373 billion in shipments during 2012. California has the largest plas-

tics industry employment,

but as a percentage of total

non-farm employment, the

industry is most important

to Michigan, where it ac-

counts for 15.8 of every 1000

non-farm jobs. Indiana is a

close second.

When suppliers to the

plastics industry are in-

cluded, jobs grow to 1.41 mil-

lion, and total shipments

reach $456 billion. The

plas-

tic products

portion of the in-

dustry was the eighth largest

U.S. industry in

2011, while the

plastic materials and syn-

thetics

sector (including

rubber and fiber) was the

twelfth largest.

Employment in plastics

manufacturing grew 0.1%

per year from 1980 to 2012,

outpacing manufacturing as

a whole, and shipments grew

at a 2.3% annual rate from

1980 to 2012. The recent industry slowdown largely reflects the recession

and slowing of the manufacturing sector as a whole.

The plastics industry has improved over the past two years.

Although manufacturing is still the main outlet for plastics, an in-

creasing share of plastics is going into services including wholesale and re-

tail trade; finance, insurance, and real estate; and healthcare. The U.S.

plastics industry, as documented by government data, operated an esti-

mated 15,949 manufacturing establishments in 2012 excluding businesses

that produce captive plastic products or supply goods and services to the

plastics industry.

For more information, visit

www.plasticsindustry.org.

ADVANCED MATERIALS & PROCESSES •

APRIL 2014

4

spot l ight

feedback

market

Just one word: Plastics

More on Metallurgy Lane

Our American metals history is so

interesting, especially when it includes

descriptions of why things happened. I

can see that Charles Simcoe, author of

the new “Metallurgy Lane” series, spent

a lot of time on his research including

extensive travel. The most surprising

thing I learned from the article is that

anthracite coal was used directly for fuel

in blast furnaces. I wonder if he came

across the historical Greenwood Fur-

nace* in Eastern Pennsylvania, and

whether or not the Cornwall open pit

mine* near Harrisburg is still operating?

Edward Dunn

[I was aware of the Greenwood Furnace,

but didn't know it was an ASM Historical

Landmark until I did some research after

Dunn’s email. The Cornwall mine closed

after the underground part flooded dur-

ing Hurricane Agnes in 1972 and the

open pit was abandoned in 1973. It had

been in operation for more than 230

years.—Charles R. Simcoe]

Pig iron production

I’d like to add a side note about pig

iron production. The blast furnaces

near St. James, Mo., (circa 1830) used

“long leaf” pine charcoal at the rate of

three tons of charcoal per ton of iron

produced. The two furnaces produced

about 16 tons of pig per day, hence

used 24 tons of charcoal. Pine pro-

duces very little charcoal compared to

hard woods, so vast stretches were de-

nuded. No replanting was done and

rain washed away what little soil was

there to begin with. The railroads took

the rest of the pines for ties (circa 1850-

1870). Today the Ozarks have only

scrub oak and cedar. The irony (pun in-

tended) is that the major industry there

today is still charcoal, now used in our

country’s barbeque pits!

Chuck Dohogne

Wonder of the world

Charles Simcoe wrote a good article

on wrought iron (February issue), but he

failed to mention one of the wonders of

human civilization—the Ashoka Pillar

(Delhi Iron Pillar*) in India. It was manu-

factured sometime around the 4th cen-

tury and has stood on open ground

since. It has neither weathered nor

shows any signs of rust or pitting.

Ashok Bhambri

*ASM Historical Landmarks. See more at

www.asminternational.org/membership/awards/historical-landmarks.

We welcome all comments

and suggestions. Send letters to

frances.richards@asminternational.org.

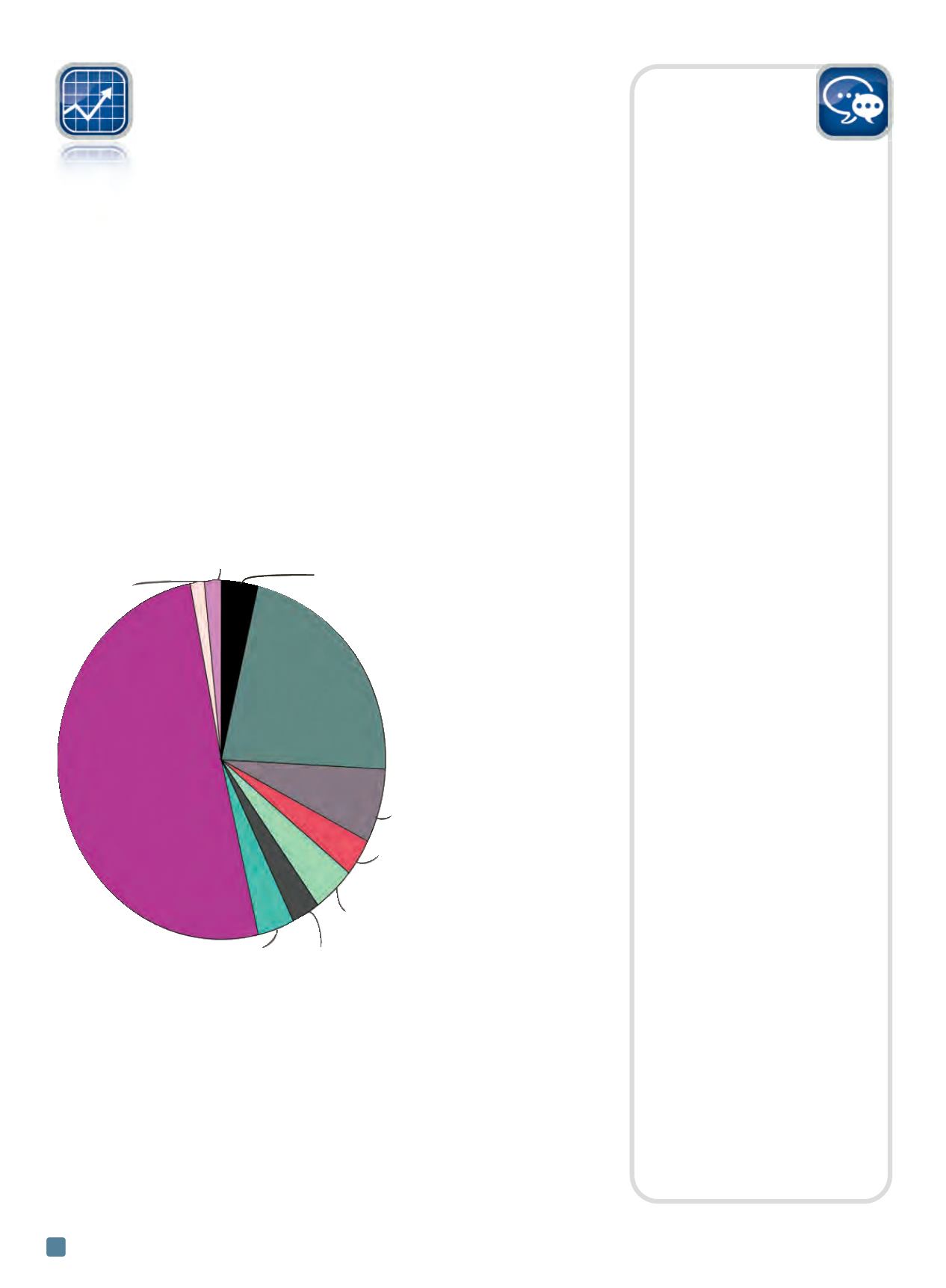

Plastics Industry Employment by Sector, 2012

Plastics work-

ing machinery,

1.3%

Molds for plastics,

1.6%

Wholesale, 3.7%

Captive plastic

products,

22.3%

Plastic materials

and resins, 6.5%

Plastic (except

packaging) film

and sheet, 4.0%

Plastic

bags,

3.5%

All other,

50.5%

U.S. total: 891,600

Source: SPI,

www.plasticsindustry.org.

Plastic bottles,

3.7%

Urethane and

other foam

products,

2.8%