ADVANCED MATERIALS & PROCESSES •

MARCH 2014

45

come worse as more stringent quality

specifications in mechanical proper-

ties (e.g., hardness variations across

the coil) were anticipated.

Three recommendations were offered

after examining the operation by com-

bining results of process analytics with

process model (phenomenological and

neural-network) simulations: (1) clas-

sifying coils in a different manner for

stacking in the furnace charge, (2) es-

tablishing new chemical composition

specifications for coils to be annealed,

and (3) creating new model-based

process cycles (temperature and soak-

ing time) for different coil classes. The

integrated approach reduced overall

rejection rates and downgrading rates

for two major products by 44 and 60%,

respectively, thereby enabling the de-

sired tightening of quality specifica-

tions. The reduction in rework and

downgrading also significantly re-

duced the plant’s specific energy con-

sumption. Achieved benefits were

monitored and sustained for more

than one year

[2]

.

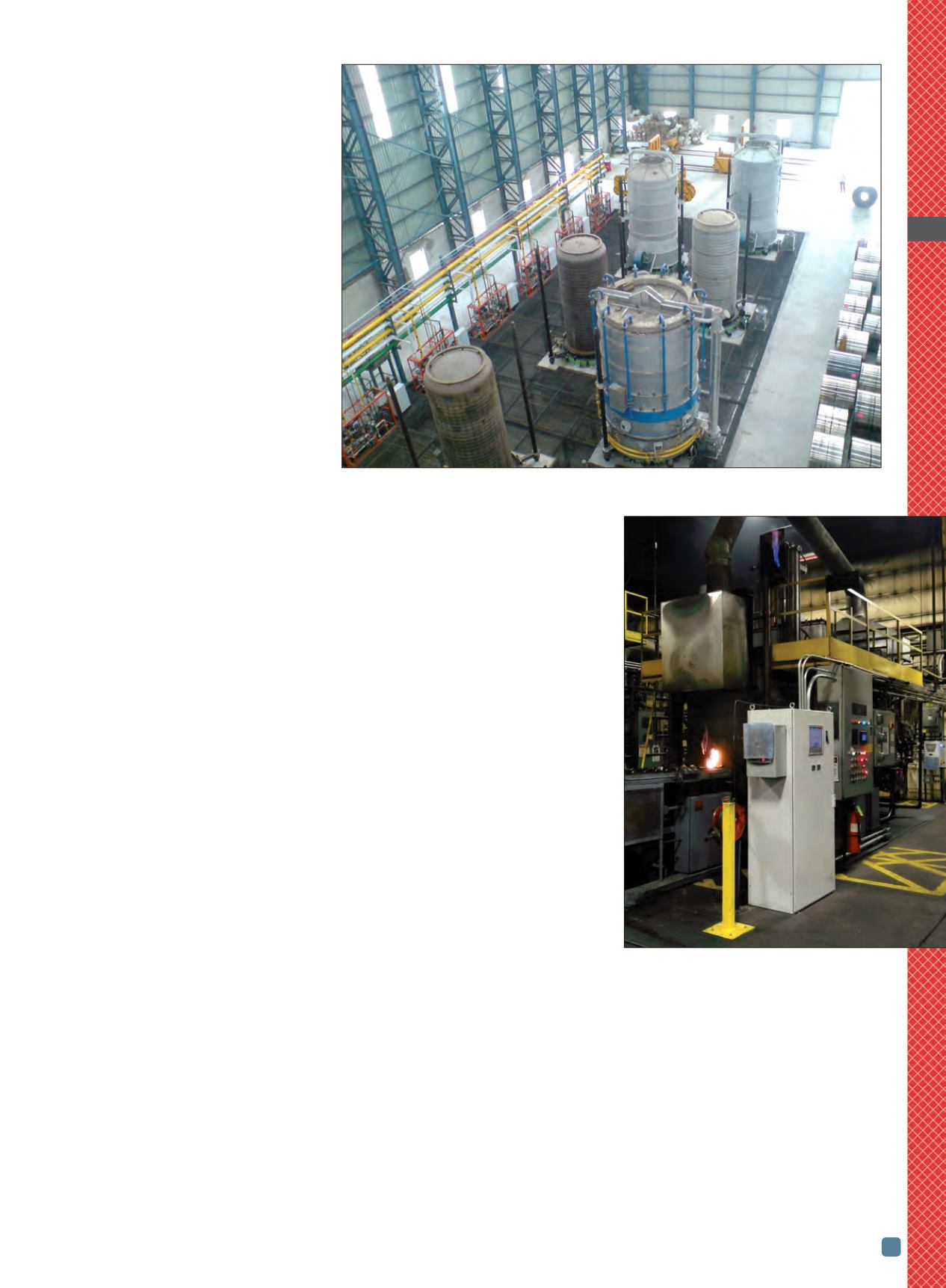

Automated coil batch annealing.

In an-

other study, an automated batch an-

nealing operation in an integrated steel

plant was analyzed and optimized

[3]

.

The modern operation was equipped

with a model-based control system,

which simulated the process and de-

rived optimized recipes before heat

treating individual stacks of coils. In the

study, process and quality data were an-

alyzed and compared with physics-

based models, which showed that the

thermal model used in the control sys-

tem was very conservative in estimat-

ing heat transfer across the coils. As a

result, process cycle time did not vary

with the thickness of the coil stack. In

addition, the control system was only

based on thermal differential across the

coils, so nonisothermal effects arising

from complex recipitation/recrystal-

lization/grain growth mechanisms were

not captured. Because of the non-

isothermal effect, accelerated annealing

kinetics with a reduction in heating rate

was observed through physics-based

modeling and laboratory kinetics ex-

periments. An appropriate thermal

conductivity model and nonisothermal

models were used to create transfer

functions for the process recipe derived

from the control system to modify the

resulting recipes. This approach was

validated on an industrial scale, and

overall productivity of the 1-million

ton/year integrated steel plant was im-

proved by 9%

[3]

together with a consid-

erable reduction in specific energy cost.

Batch carburizing.

In a recent study, a

carburizing operation of a modern

heat treating shop was analyzed, mod-

eled, and optimized. The heat treating

operation has 12 quench-sealed fur-

naces for heat treating transmission

components such as gears and shafts.

About 500 MB of data comprising

charge characteristics (dimensions,

number of parts, charge configuration,

and weight), process parameters (fur-

nace temperature-time and carbon po-

tential-time records of various

segments, and oil temperature-time)

and quality (case depth, microstruc-

ture, hardness, and retained austenite)

were extracted for the operation for a

one-year period. All data were

recorded with different periodicity. For

example, furnace process data were

recorded every minute, whereas qual-

ity data were recorded per batch. Raw

process data (time, temperature, and

carbon potential) were transformed

from a per minute basis into a per

batch basis with the mean and stan-

dard deviations values. Subsequently,

process data were merged with charge

HTPRO

9

Fig. 2 —

Representative coil batch-annealing operation.

Fig. 3 —

Representative carburizing

operation with integral quench furnaces.