ADVANCED MATERIALS & PROCESSES •

MARCH 2014

43

HTPRO

7

less) and complex dynamic thermal geo-

metric profiles, these dynamics cannot be

accurately recorded nor can they graphi-

cally display the part’s internal thermal re-

sponse and reactions. The dynamics

inhibit a more complete understanding

and evaluation of the multiple reaction is-

sues involved, limiting the ability to estab-

lish an optimal process. However,

because induction heating is electrically

applied and fully electronically controlled,

it can be mathematically modeled and ob-

jectively simulated (via “what if” studies).

The resultant graphics display provides a

detailed representation of the dynamic

interactions involved to help better un-

derstand the process.

Challenges and limitations of under-

standing the process are fully addressed,

and actual dynamics can simulated by

using the latest induction computer

modeling programs—including fully

coupled, electromagnetic/thermal and

FEA/FED modeling. This approach

enables graphical display of complex

thermal logistics and subsequent inter-

reactive reactions to understand the

process, make adjustments, and identify

optimal reactions/process parameters/

dynamics to improve part performance.

Coupling material science and simula-

tion process engineering provides an ad-

vanced understanding and review of

viable alternative solutions.

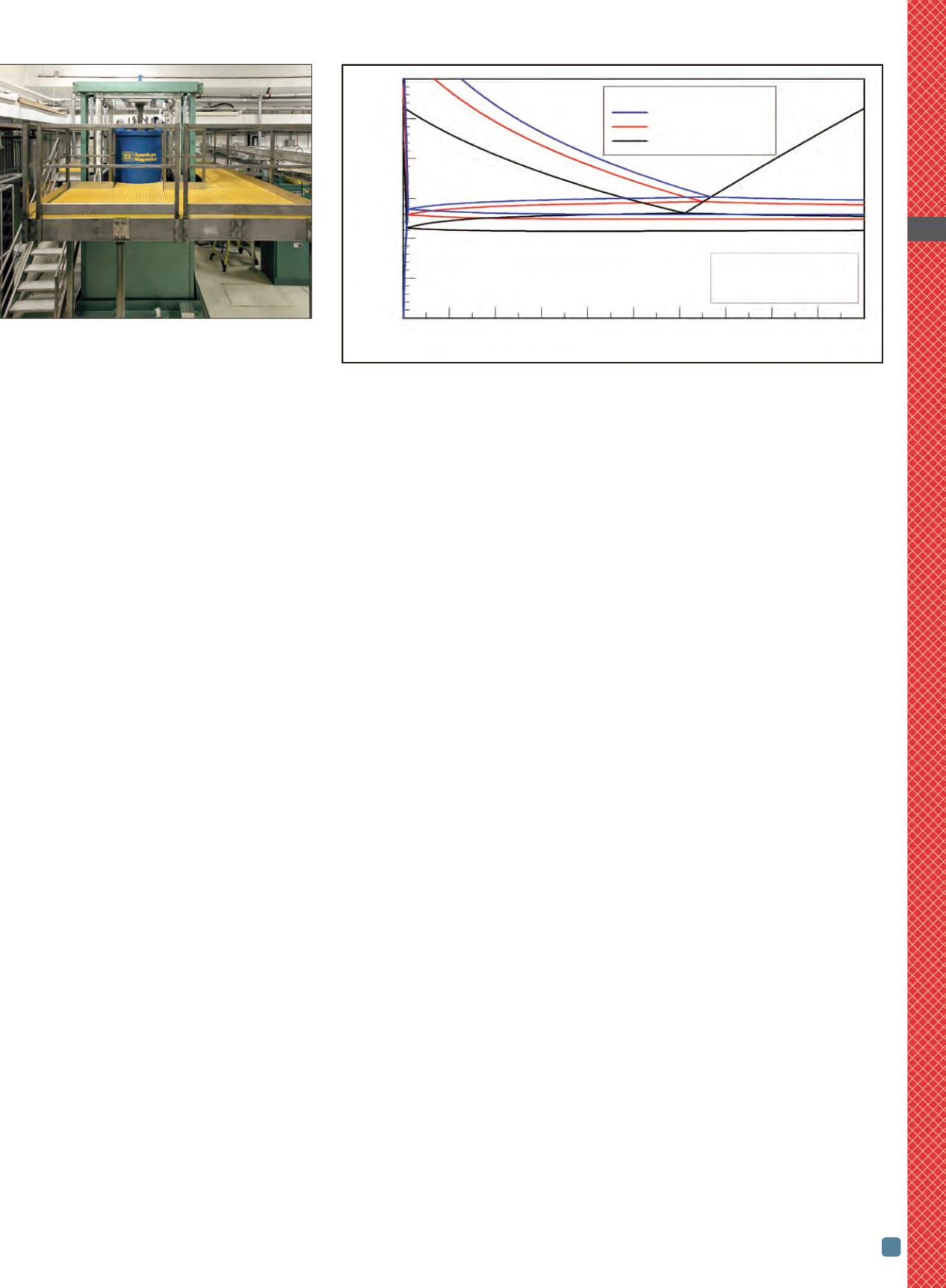

High magnetic field processing (HMFP)

A new high magnetic field processing

(HMFP) and thermomagnetic field pro-

cessing (TMFP) facility at Oak Ridge Na-

tional Laboratory, Tenn., includes an

industrial-scale HMFP facility with an in-

tegrated induction heating and quench-

ing capability for conducting industrial

experiments (Fig 1). Coupling a high

magnetic field environment with an ap-

plied induction elevated temperature ca-

pability offers an enabling disruptive

technology. This approach enables

achieving stronger, more durable compo-

nents and materials with improved per-

formance. Induction heating plus a high

magnetic field processes parts much

faster than thermal processing alone be-

cause the magnetic field alters the phase

equilibrium diagram (Fig. 2). It shifts

phase-transition temperatures, and phase

solubilities increase with increasing tem-

perature. Other benefits include:

• Accelerated phase transformations

• Enhanced nucleation and growth

during phase transformation

• Smaller grain size

• Less segregation during solidification

• More homogeneous microstructure

and properties

• Higher strength and plasticity

• Lower residual stresses

• Faster diffusion

Such a technology offers the means to

make significant major science and tech-

nological advancements in developing

the next generation of novel structural

and functional materials for use in a

broad range of transportation and mili-

tary applications.

All materials are influenced by high

magnetic fields, so all material systems

from metallic through polymeric and

protein will respond to an induction

thermal high magnetic field (ITHMF)

environment. Major improvements in

performance (from 15 to 300%) can be

manifested in mechanical and/or physi-

cal properties. For example, an ITHMF

(9 T) processed Hy Tuf vacuum arc

remelted high-strength, low-alloy steel

(Latrobe Specialty Steels Co., Pa.) has an

equivalent ultimate tensile strength and

double the toughness of a more expen-

sive conventionally processed 250

maraging steel grade.

Development of nanocrystalline and tex-

tured and/or novel microstructures and

reaction paths is made easier and faster

through the synthesis and catalytic chem-

ical effect of the extreme ITHMF envi-

ronment. In addition, the deformation

behavior (magnetoplasticity) of materials

appears to be influenced by high mag-

netic fields, potentially enabling high- and

low-cycle fatigue damage mitigation (life

extension), superplastic behavior at am-

bient temperature, residual stress relief,

and other visionary applications. It might

even be possible to make classically brit-

tle materials formable under high mag-

netic fields. Therefore, the ITHMF

environment has an impact on phase

equilibria and kinetics and represents a

new synthesis/catalysis paradigm and a

deformation/life enhancement process-

ing breakthrough technology.

HTPRO

Acknowledgement:

The authors thank

Dr. Gerard Ludtka and Dr. Gail Ludtka,

Oak Ridge National Laboratory, Tenn., for

input from their research on this technol-

ogy conducted at ORNL.

For more information:

George Pfaffmann

is vice president of technology, Ajax

TOCCO Magnethermic Corp., 30100

Stephenson Hwy., Madison Heights, MI

48071, 248/691-2281,

gpfaffmann@ ajaxtocco.com,

www.ajaxtocco.com.

Fig. 1 —

ITHMF setup at ORNL consists of

a commercial prototype 9-T, 8-in. diameter

by 9-in. long uniform field strength

superconducting magnet to conduct large-

scale experiments.

Fig. 2 —

The application of a high magnetic field on an AISI 1045 carbon steel shifts all

phase equilibria.

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Carbon, wt%

1045 carbon steel

7 T magnetic field

5 T magnetic field

No magnetic field

g

- fcc

a

- bcc

Fe 3 C – orthorhombic

a

+

g

g

Fe 3 C +

g

a

+ Fe 3 C

900

850

800

750

700

650

600

Temperature, ºC