ADVANCED MATERIALS & PROCESSES •

MARCH 2014

44

Modern industrial heat treating oper-

ations have sophisticated IT architec-

tures, where significant amounts of

data in GB/TB per year are generated

including characteristics of input ma-

terial (chemistry, prior material qual-

ity, charge dimensions, quantity, and

configuration), process parameters

(furnace temperature, carbon poten-

tial, and quenching oil-temperature

variation with time) and product qual-

ity (hardness, microstructure, case

depth, and distortion) are generated.

These manufacturing data are prima-

rily used for process audits and trou-

bleshooting specific batches that have

quality issues.

Much of this collected data goes un-

used. However, it could be significantly

leveraged to generate process insight

and optimize processes to improve

manufacturing efficiency and product

quality for an overall reduction in oper-

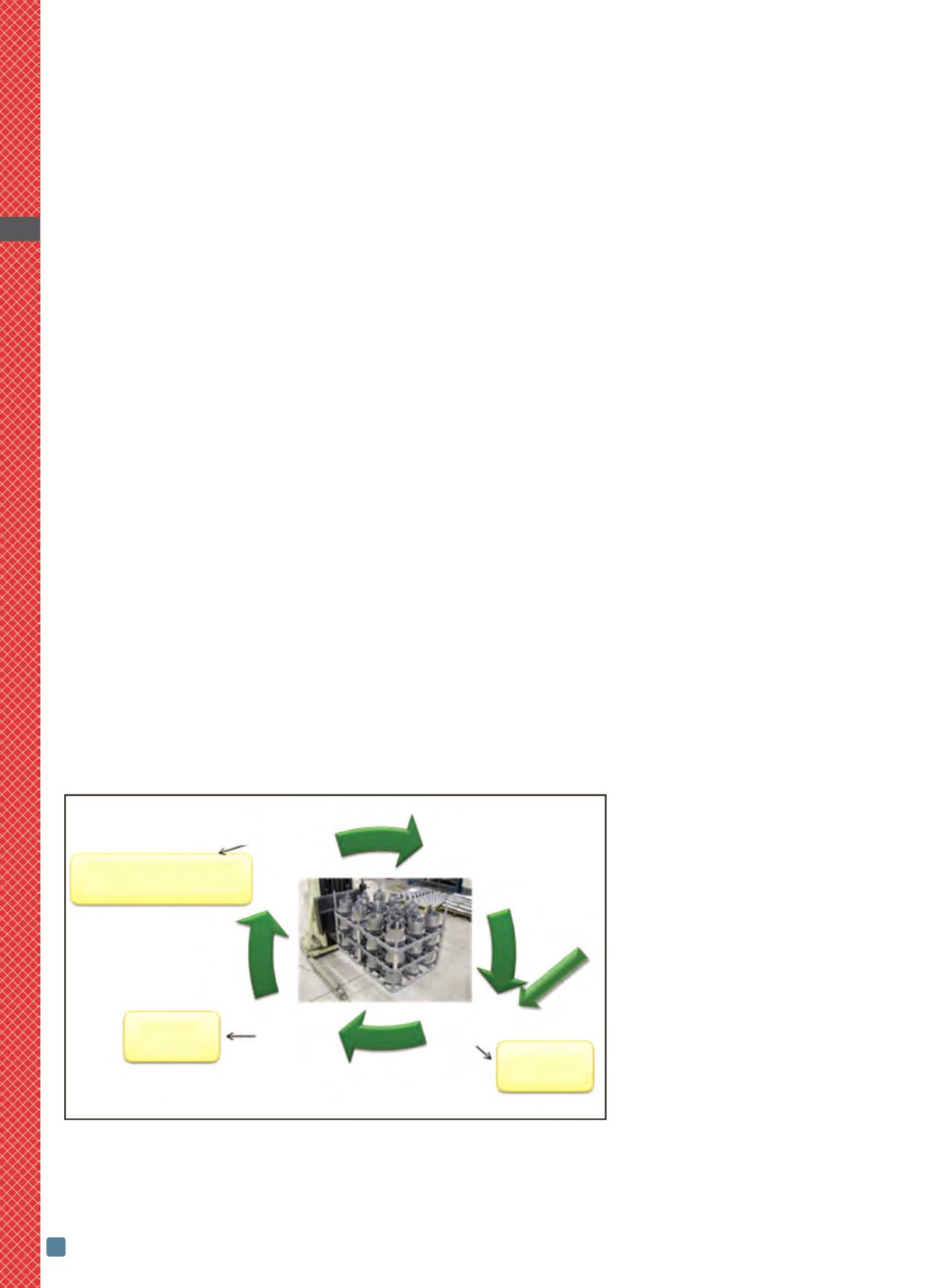

ational and energy costs. Figure 1 illus-

trates that this could be achieved in a

closed loop, where the manufacturing

data together with heat treating knowl-

edge can be synthesized with physics

and data-based modeling approaches to

generate insight for process optimiza-

tion and control. Actionable outcomes

at different phases of the loop are also

shown in the figure. For example, many

surprises about process and product

can emerge from process analysis and

modeling, where the insight generated

from this approach could directly im-

pact product quality and design recom-

mendations. This could enhance key

process efficiency metrics—namely, op-

erational and energy costs, productiv-

ity, and quality.

This approach is an expanded, generic

view of a typical smart-manufacturing

circle

[1]

comprising Data-Analyze-

Model-Apply. Big data, data analytics,

and data-based modeling approaches

(neural network, principal compo-

nent analysis, and other advanced sta-

tistical methods) are emerging as key

areas to analyze manufacturing oper-

ations. Data-based approaches are ef-

fective to generate predictions within

a current operating regime from

which data are derived.

In contrast, physics-based models can

also lead to an optimum operating

condition, which is far removed from

current conditions. Physics-based

models for heat treating operations

incorporate mass and energy conser-

vation, laws of heat transfer, metallur-

gical thermodynamics, and chemical

reactions and kinetics. Some impor-

tant physics-based models with re-

spect to carburizing include thermal

models, diffusion kinetics, quenching

models, residual stress, and distortion

models. A judicious synthesis of these

two approaches and modeling

methodologies is far more effective

than focusing on individual compo-

nents of the process.

Case studies

Coil batch annealing.

This generic ap-

proach was effectively demonstrated

by the significant improvement in

first-pass yield of an industrial batch

annealing operation in a secondary

cold-rolling mill

[2]

. The operation had

many operating challenges including

the need to process coils with high

variability from different sources,

pressure to maintain a low inventory

level, and a lack of a process model

that could customize cycle design for

individual coil stacks. As a result,

more than 50% of annealed coils

failed to meet target quality require-

ments, resulting in product down-

grade, or rework that added

significant cost to meet product qual-

ity. The situation was expected to be-

ANALYTICS, MODELING, AND OPTIMIZATION OF

INDUSTRIAL HEAT TREATING PROCESSES

MANUFACTURING DATA ARE PRIMARILY USED FOR PROCESS AUDITS AND TROUBLESHOOTING

SPECIFIC BATCHES THAT HAVE QUALITY ISSUES, BUT COULD BE LEVERAGED TO GAIN INSIGHT

FOR OVERALL PROCESS OPTIMIZATION AND CONTROL.

Satyam S. Sahay, FASM* and Goutam Mohapatra,

John Deere Asia Technology Innovation Center, Pune, India

Robert Gaster*,

John Deere Moline Technology Innovation Center, Ill.

Hema Guthy*,

John Deere Coffeyville Works, Kan.

8

HTPRO

*Member of ASM International

Fig. 1 —

Manufacturing data together with heat treating knowledge can be synthesized

with physics and data-based modeling approaches in a closed loop to provide insight

for improving process efficiency and product quality for overall reduction in operating and

energy costs.

Optimize

and

control

Data

Heat treat

knowledge

Analysis,

Insight modeling

and

recommendations

Surprises?

R&A, design

Process efficiency

Cost, productivity, quality