edfas.org

45

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 4

GUEST EDITORIAL

CONTINUED FROM

PAGE 2

from the 130 nm to the 14 nm nodes. Solutions over this

period can be subdivided into those resulting from:

• Enhancement of existing analytical techniques

• Development/applicationof newanalytical techniques

• Development of new analysis approaches and/or

sample-preparation methodologies

An example of the enhancement of existing analytical

techniques lies in the introduction of spherical aberration

correction in scanning electronmicroscopy and transmis-

sion electron microscopy (TEM)/scanning transmission

electron microscopy (STEM). The fact that TEM/STEM are

projection techniques has pushed the need for tomog-

raphy and holography, with multiple approaches now

available. Note: Although thediffraction limit of TEM/STEM

is significantly smaller than that of atomic dimensions,

the spatial resolution noted in tomography/holography

now lies in the nanometer range.

Examples of the application of new techniques over

this period may have included, but are not limited to,

conductive atomic forcemicroscopy, scanning spreading

resistancemicroscopy, infrared atomic forcemicroscopy,

tip-enhanced Raman spectroscopy, and so on.

An example of a new analytical approach lies in the

application of large-area techniques over areas populated

with periodic repeating structures (for example, a sea of

fins over 50 by 50 µm areas or larger). These have been

found to be useful in providing data beyond the diffrac-

tion limit of the respective technique. Examples include

secondary ion mass spectrometry (SIMS) in the form of

1.5-D SIMS, x-ray diffraction, critical-dimension small-

angle x-ray scattering, and so on.

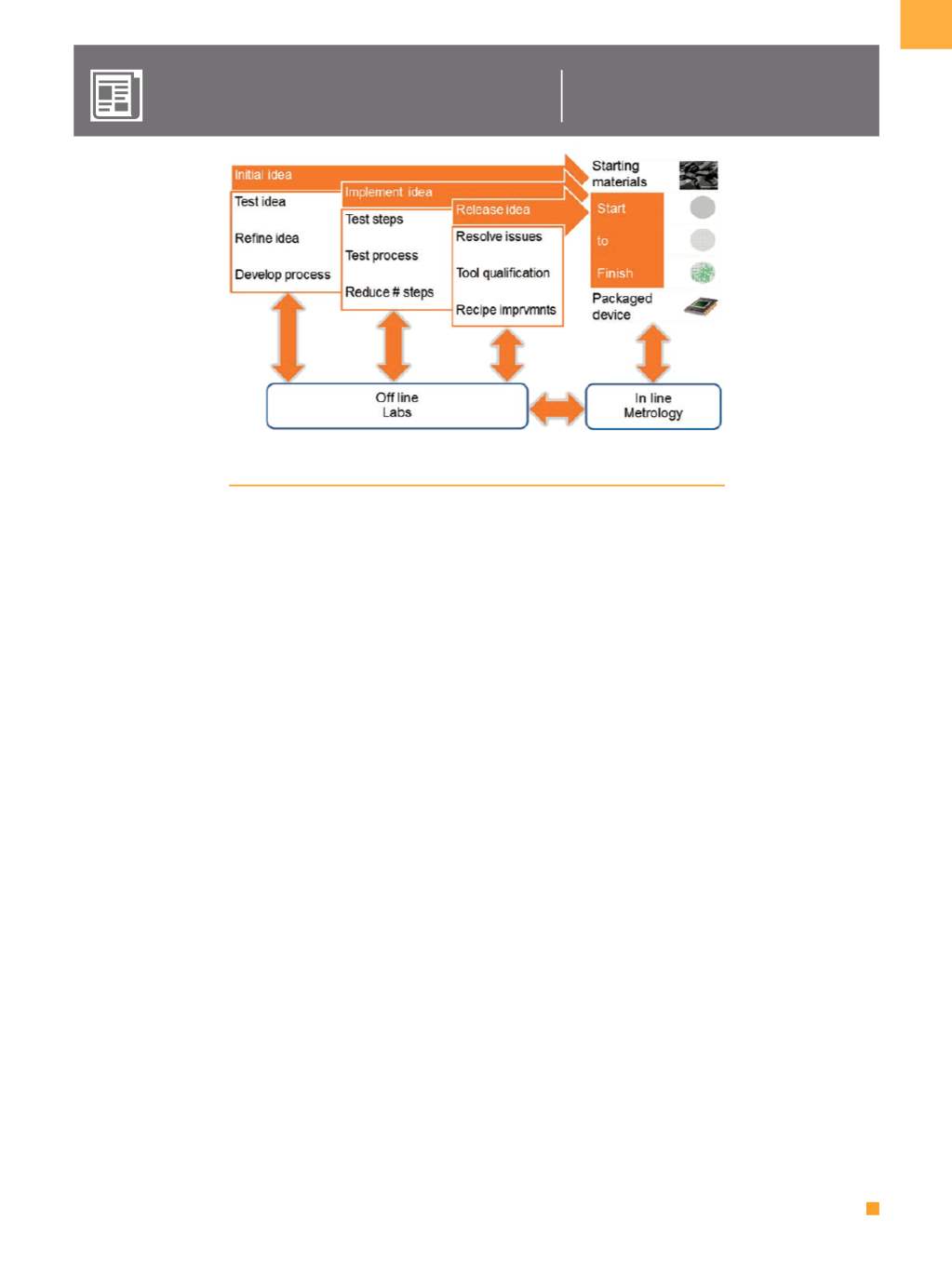

Fig. 1 Requirements of the FA labs in

supporting R&D efforts

The demands on the FA labs are then taken to the next

level if the respective HVM site is also involved in research

and development (R&D). This is realized because the

labs are critical in idea development through to process

implementation and refinement, as illustrated in Fig. 1.

The difference between the FA labs and metrology in this

figure stems from the fact that the former is involved in

process development (inclusive of evaluating newmateri-

als), process qualification, process refinement, through to

the examination of process issues, while the latter is pri-

marily concernedwith process control, with some degree

of issue/yield understanding also included (sometimes in

separate departments). This also brings into question the

terminology used (that of “FA labs”), as this would tend

to describe a subset of their overall scope, that is, implies

yield learning only as opposed to materials, device, and

process learning.

Alongwith the FA lab capabilities are the expectations

that the analytical techniques provide:

• High level of precision and repeatability

• Fast turnaround/cycle time

• Cost-effectiveness

• High uptime

Reasons for precision/repeatability lie in the fact that

the respective process step or steps must be controllable

to predefined upper and lower limits, which, in some

cases, reach subatomic dimensions. (Although interre-

lated, device response is dictated by electric fields, not

atomic dimensions.) The remaining three items can be

tied directly to the financial stakes in semiconductor HVM.