FEATURE

A D V A N C E D M A T E R I A L S & P R O C E S S E S | S E P T E M B E R 2 0 1 6

4 2

10

CONTINUOUS DEW POINT MONITORING SYSTEM

FOR A SINTERING FURNACE

Accurate dew point measurement is key to maintaining the atmosphere composition

required to achieve high quality and consistency of sintered products.

Liang He,* Zbigniew Zurecki, FASM,* Donald Bowe, and Ranajit Ghosh,*

Air Products & Chemicals Inc., Allentown, Pa.

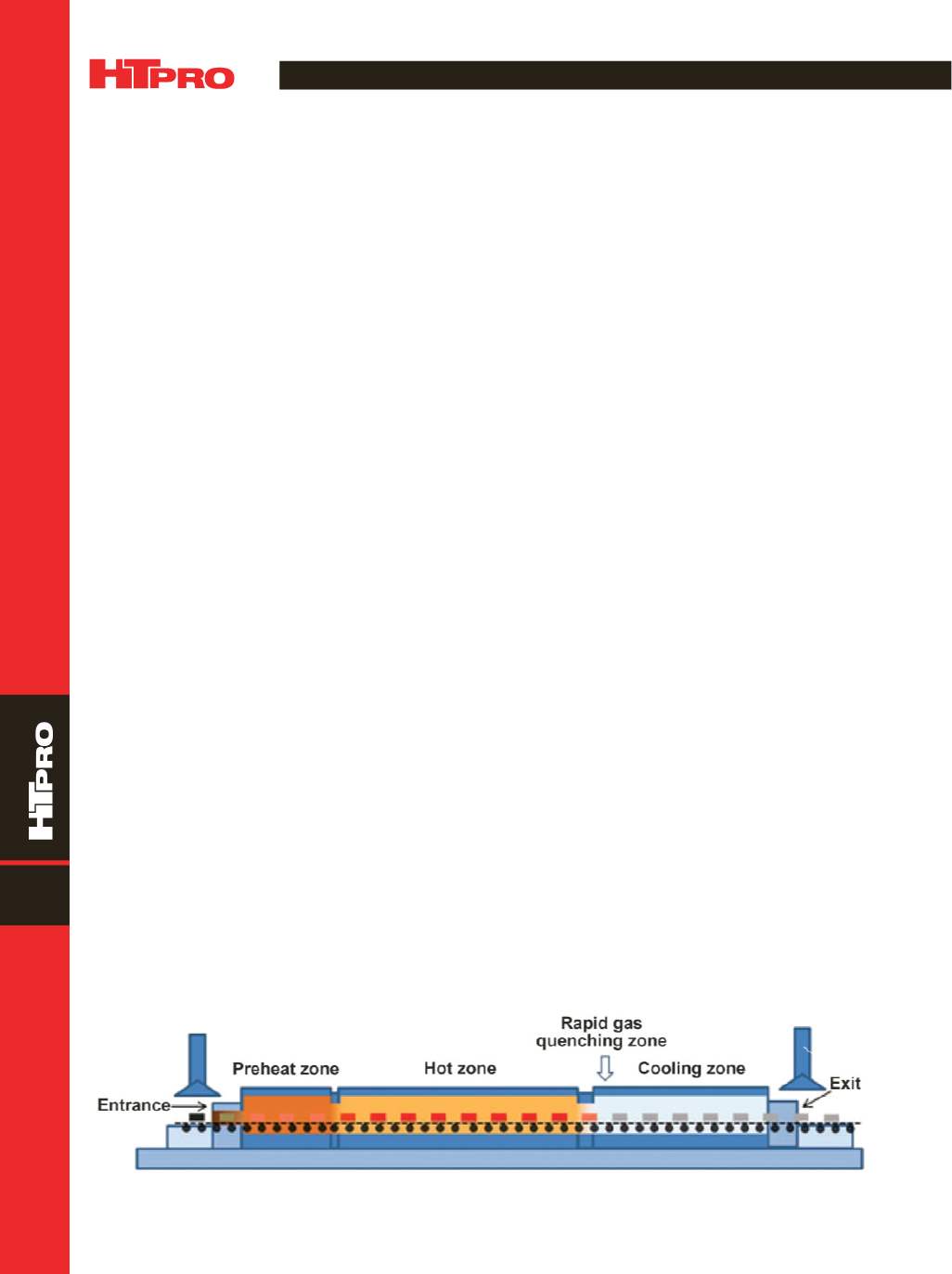

C

ommon powder metallurgy (PM) techniques involve

compacting a blend of metal powder with lubricant

and graphite (for ferrous parts) into a green part in

a press, and sintering the part in a batch or continuous fur-

nace. Continuous mesh-belt furnaces are widely used for

mass production of PM parts

[1]

. They typically have at least

three zones—a preheating (or de-lubrication) zone, a hot (or

sintering) zone, and a cooling zone. In addition, some con-

tinuous sintering furnaces have a specially designed rap-

id-cooling zone between the hot and cooling zones for sinter

hardening steel parts. Figure 1 shows a typical continuous

sintering furnace design.

WHY DEW POINT IS IMPORTANT

Atmosphere quality plays a key role in the final prop-

erties of a sintered part. Dimensional accuracy as well as

characteristics such as hardness, ductility, carbon content,

microstructure, and magnetic properties are influenced not

only by time and temperature, but also by furnace atmo-

sphere composition, flow rate, and stability. Different fur-

nace zones require varying degrees of oxidizing or reducing

power to develop optimum final sintered part properties

[2]

.

Generally, a reducing and carbon-neutral atmosphere is

desired in the hot zone for ferrous parts.

The

reducing potential

determines the rate at which

powder particle surface oxides are reduced, which directly

influences sintering bonding between particles in the com-

pact. A dry or slightly humidified

[1]

nitrogen-hydrogen blend

is used for steel PM operations. The hydrogen-to-moisture

ratio in the hot zone determines reducing capability. Mois-

ture is simply a product of powder oxides reduced by hydro-

gen introduced into the furnace, as well as belt reduction

and air ingression. Properties of sintered parts, such as

surface hardness and strength, are affected if uncontrolled

carburization or decarburization occurs. In a carbon-neutral

atmosphere based on nitrogen with hydrogen addition, the

actual hydrogen-to-moisture ratio in the sintering zone can

be used as the control parameter. For example, in nitrogen

and hydrogen sintering atmospheres, maintaining an atmo-

sphere dew point (DP) below −30°F ensures a reducing and

carbon-neutral hot zone for common steel grades used in

gear manufacturing

[3]

.

Thus, monitoring and controlling hot-zone atmosphere

DP is necessary for better sintering process control and pro-

duction cost control

[4]

. Continuously measuring DP enables

real-time monitoring of the furnace condition. For example,

a sudden, extremely high (wet) DP reading may indicate a

leak in the muffle or cooling zone inside the furnace.

SELECTING THE CORRECT DP SENSOR

Ceramic and polymer-based capacitance DP sensors

are popular in the heat treating industry due to their low

cost, fast response, and long service life. Alumina (Al

2

O

3

) is

a preferred ceramic sensing material for DP sensors, and

current Al

2

O

3

DP sensors are fabricated by an anodization

process. One limitation of these sensors is that significant

degradation in sensitivity and drift in capacitance charac-

teristics occur after long exposure to high humidity. This is

attributed to the gradual decrease of effective surface area

and porosity caused by water absorption

[5]

.

Fig. 1 —

Typical design of a continuous sintering furnace.

*Member of ASM International