FEATURE

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

S E P T E M B E R

2 0 1 6

4 7

15

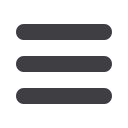

Fig. 3 —

Boronized surfaces: (a) unground and (b) ground.

Fig. 4 —

Boride layer on (a) ground and (b) as-printed surfaces. Boride layer depth

range: 0.0010-0.0011 in. Boride layer hardness (three locations): 2670, 2778, and 2892

HV (50 g load). Core hardness (four locations): 36.5, 39, 39, 39 HRC. Etchant: Marble’s

reagent. Original magnification 200

x

.

Fig. 5 —

Core microstructures. Etchant:

Marble’s reagent; (a) original magnifica-

tion 50

x

and (b) original magnification

200

x

.

COMPARING WROUGHT AND AM MATERIALS

A sample of Inconel 718 bar stock material was also

processed to compare results with those of the 3D-printed

material. Figure 6 shows the microstructure of the boride

layer on the bar stock test bar. It was concluded that boroniz-

ing of 3D-printed Inconel 718 is possible, and boride layer

depth, hardness, and microstructure are similar to results

for wrought Inconel 718.

For more information:

Craig Zimmerman is technical

director, Bluewater Thermal Solutions, 414.573.2832,

czimmerman@bluewaterthermal.com, www.bluewater-

thermal.com.

Fig. 6 —

Boride layer on wrought Inconel 718 test bar. Boride

layer depth range: 0.0012-0.0013 in. Boride layer hardness

(three locations): 3014, 2778, and 2892 HV (50 g load). Etchant:

Marble’s reagent. Original magnification 200x.

(a)

(b)

(a)

(b)

(a)

(b)