A D V A N C E D M A T E R I A L S & P R O C E S S E S | S E P T E M B E R 2 0 1 6

3 8

6

FEATURE

OBTAINING NADCAP ACCREDITATION: HELPFUL GUIDELINES

FOR PASSING YOUR AUDIT, PART II

Learn how to simplify the process of obtaining Nadcap accreditation for your heat treating

facility by paying heed to some of the challenges others have experienced.

Nathan Durham,

Ipsen USA, Cherry Valley, Ill.

A

erospace Material Specification (AMS) standards

and the Nadcap accreditation process play key roles

in ensuring that manufacturers performing heat

treating and other special processes adhere to consistent,

high-quality standards for producing aerospace products.

While preparing for a Nadcap audit can seem daunting, a

series of articles has been developed that discusses some

of the recommended resources for obtaining a better under-

standing of how to prepare for and execute a successful

audit. The first part of this series (June 2016,

HTPro

) looked

at preparing for and scheduling an audit. This article looks at

the internal audit process, nonconformances, and complet-

ing the internal audit.

UNDERSTANDING THE INTERNAL

AUDIT PROCESS

It is necessary to understand exactly what is required

when preparing for an official Nadcap audit. Internal audits

involve performing quality system audits (e.g., AS9001 or

AC7004) and real job audits, as well as reviewing past tem-

perature uniformity surveys (TUS), system accuracy tests

(SAT), leak back tests, maintenance logs, and industry

specifications. It is required that audit checklists (available

on eAuditNet) are used during an internal audit to ensure

adherence to key specifications, as well as to help identify

any potential findings.

Prior to submitting internal audit results to Per-

formance Review Institute (PRI) as proof of completion,

some recommend performing additional internal audits to

become more familiar with the process of going through

an audit, as well as to work through the implementation of

any necessary corrective actions. An alternative approach is

to hire an outside consultant to perform the internal audit,

which could provide a more realistic perspective of what

might occur during the official audit.

Throughout the audit, you must record where system

requirements are met and where there is objective evidence

of compliance. Examples of objective evidence include notes

that refer the auditor to a specific section in the Quality Man-

ual, reference training files in the production manager’s

office, or direct the auditor to the sales manager for cus-

tomer satisfaction surveys.

While discussing best practices for performing an inter-

nal audit, we found that the requirement of conducting

live job audits (with either real or sample aerospace parts)

makes it easier to identify potential nonconformances that

the auditor might find during the official Nadcap audit. It is

also required to review a balance of live and historical job

audits; specifically, you must perform a minimum of 10 job

audits, with at least two job audits for each Prime. However,

regardless of which audits are performed or prepared, it is

essential to make sure all records are in order for the official

audit as the auditor could ask to see anything—from paper-

work for a job that occurred threemonths ago to TUS results

for initial surveys from several years ago.

PREPARING FOR JOB AUDITS

There are some recommended best practices for per-

forming job audits during the internal and official audit that

can help contribute to a successful audit process.

Do you know the instrumentation type?

As part of the job

audit, auditors will verify that you aremeeting all the require-

ments of AMS 2750. Therefore, it is essential to have records

on hand that clearly demonstrate you are meeting the

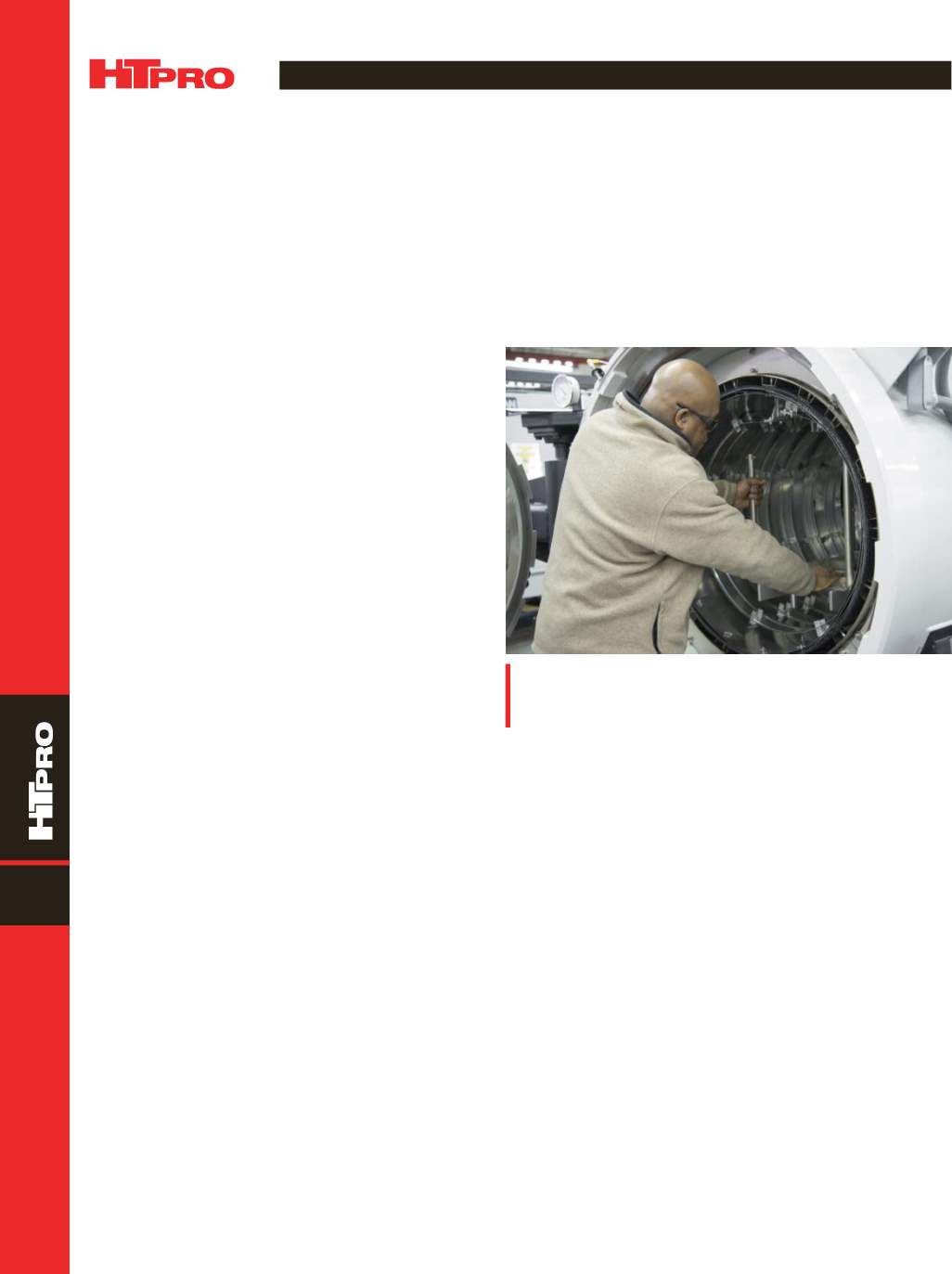

A key step for performing a successful Temperature Uniformity

Survey is ensuring the survey fixture is carefully placed within

the hot zone. Courtesy of Ipsen.