iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 6

4 8

iTSSe

TSS

10

FEATURE ARTICLE

COLD SPRAY: ADVANCED

CHARACTERIZATION METHODS—PART I

This new article series explores the indispensable role of characterization in the development of cold

spray coatings and illustrates some of the common processes used during coatings development.

Dheepa Srinivasan,

GE Power, GE India Technology Center, Bangalore

M

aterials characterization is an inherent aspect of the

cold spray coating evaluation process. Characteriza-

tion of as-sprayed microstructures enables develop-

ment of an understanding of the thermomechanical evolution

of the coating and elucidates the bonding mechanisms both

within the coating and at the coating-substrate interface. Eval-

uating coating residual stress and coating relaxation behavior

after thermal treatments is imperative to establish the reli-

able functionality of the coating for the proposed application.

Microstructural characterization methods including optical

microscopy, scanning electron microscopy, transmission elec-

tronmicroscopy, electronbackscatter diffraction, andelectron

probe microanalysis are integral to understanding the highly

nonequilibriumprocess that enables formation of thick adher-

ent coatings via severe plastic deformation of metal powders.

Microhardness, nanoindentation, and residual stress analysis

add to a more complete understanding of the formed coating.

This article series will explore the indispensable role of

characterization in the development of cold spray coatings

and will illustrate some of the common processes used during

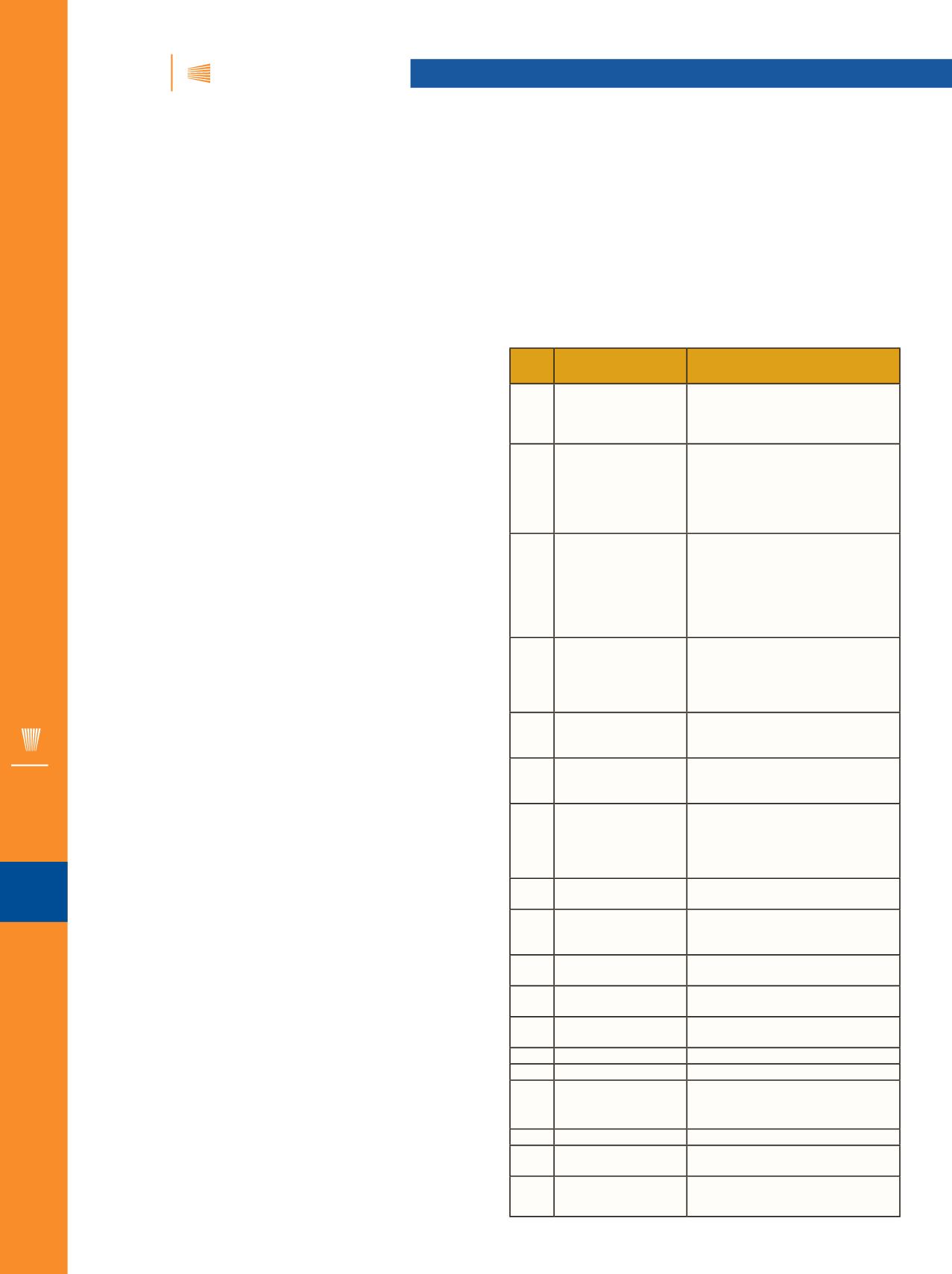

coatings development. As an overview, Table 1 provides an

exhaustive list of all the characterization techniques that can

be used for cold spray coating characterization. The table also

lists the key aspect of each technique and its relevance to

cold spray coating characterization. Not all of the techniques

listed have been used to their optimum level in developing a

complete understanding of the complex nature of a cold spray

coating.

This new series will emphasize the advanced micro-

structural characterization techniques that are used in high-

pressure cold spray coating characterization, including residu-

al stress characterization. Future article installments will also

discuss the preliminary screening tool of hardness and bond

adhesion strength, as well as a distinction between surface

and bulk characterization techniques and their importance

for cold spray coatings. Further, each article will explore a dif-

ferent characterization method, including a note on sample

preparation for characterization, which is critical and must be

followed for accurate results without any artifacts.

iTSSe

For more information:

Dheepa Srinivasan is a principal en-

gineer at GE Power, GE India Technology Center, Bangalore,

dheepa.srinivasan@ge.com,

www.ge.com. This article series is

adapted from

Chapter 5, Cold Spray—Advanced Characteriza-

tion

, inHigh Pressure Cold Spray—Principles and Applications,

edited by Charles M. Kay and J. Karthikeyan (ASM, 2016).

No. Characterization

technique

Key aspect for cold-sprayed

coating

1

Optical microscopy

Coating thickness, coating porosity,

substrate-coating interface

integrity, coating porosity after heat

treatment

2

X-ray diffraction

Feedstock powder phase evolution,

as-sprayed and heat treated coating

phase formation, coating macro-

and microstrain, coating relaxation

behavior, presence of any coating

texture

3

Scanning electron

microscopy

lntersplat interactions in the

sprayed coating before and after

heat treatment, microcracks

and micropores, coating fracture

surface, inclusions and other

phases in the coating or substrate-

coating interface

4

Focused ion beam

Preparation-specific sections for

examination in the scanning and

transmission electron microscopes,

coating splat interface or coating-

substrate interface

5

Electron probe

microanalysis

Precise chemistry, diffusion layers

in a cold-sprayed coating, coating-

substrate interface chemistry

6

Transmission

electron microscopy

Phase identification, dislocation

structure, recovery processes and

recrystallization, coating chemistry

7

Electron

backscattered

diffraction

Coating texture, extent of

recrystallization, deformation

map in the substrate, nature of

bonding in the coating and coating

substrate, grain size and orientation

8 Electron channeling

contrast

Dislocation structure, deformation

characteristics

9

Residual stress

Residual stress in the as-sprayed

coating, coating relaxation process

monitoring

10 X-ray photoelectron

spectroscopy

Chemical bonding, presence of

oxides

11

X-ray fluorescence

Presence of oxide and nature of

chemistry on coating surface

12

Auger electron

spectroscopy

Surface chemistry of the coating

13 Raman spectroscopy

Phase transitions in the coating

14

Oxygen analysis

Feedstock powder characterization

15 Surface roughness

As-sprayed coating, distinguishing

between process parameters, gas

type

16

Microhardness

Screening tool for coating

17

Nanoindentation

Coating characterization,

deformation

18 Bond adhesion test

Evaluating the adhesion and

cohesion strength of the coatings

TABLE 1

—

CHARACTERIZATION TECHNIQUES USED FOR

COLD SPRAY COATINGS AND THEIR KEY ATTRIBUTES