iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 6

4 7

iTSSe

TSS

9

RESEARCH SPOTLIGHT

deformation of thin substrates, e.g., compressive stresses of

400 MPa were measured in 1-mm-thick 304L substrate after

grit-blasting

[3]

. Thus, the technique could not be used for this

application if the shape of the parts to be covered cannot be

altered. Three plasma technologies could be used to depos-

it the ceramic coating—conventional atmospheric plasma

spraying (APS) using powder, suspension plasma spraying

(SPS), and solution plasma spraying.

APS spraying of the 0.5-mm-thick ceramic coating on

the as-received substrate after solvent cleaning to remove

potential surface contaminants made it impossible to form a

coating with good adhesion to the substrate, regardless of the

spraying conditions and temperature of the substrate. Also,

deposition of a 0.5-mm-thick ceramic coating by suspension

spraying took too long. Therefore, to circumvent this adhesion

problem, a specific procedure had to be developed. Thismeth-

od consists of deposition of a duplex thermal barrier coating

made of (i) a thin layer of yttria-stabilized zirconia (YSZ) by SPS

on the as-received and cleaned alloy and (ii) a thick layer of

YSZ by conventional APS. The SPS layer creates an increased

surface area for mechanical bonding of the APS coating and

provides the adhesion of the duplex coating to the Haynes

230 alloy.

iTSSe

For more information:

Armelle Vardelle is a professor at the

University of Limoges, France,

armelle.vardelle@unilim.fr. Por-

tions of this article have been adapted from a full length feature

in the

Journal of Thermal Spray Technology

21 (2012): 1128-

1134, DOI 10.1007/s11666-012-9798-2. © ASM International.

References

1. A Technology Roadmap for Generation IV Nuclear Energy

Systems, US DOE Nuclear Energy Research Advisory Com-

mittee and the Generation IV International Forum, Decem-

ber 2002.

2. R. Stainsby, et al., Gas Cooled Fast Reactor Research and

Development in the European Union,

Sci. Technol. Nucl.

Install.,

Article ID 238624, 2009.

3. H. Liao, et al., Determination of Residual Stress Distribu-

tion from In Situ Curvature Measurements for Thermally

Sprayed WC-Co Coatings,

J. Therm. Spray Technol.,

Vol 6(2),

p 235-241, 1997.

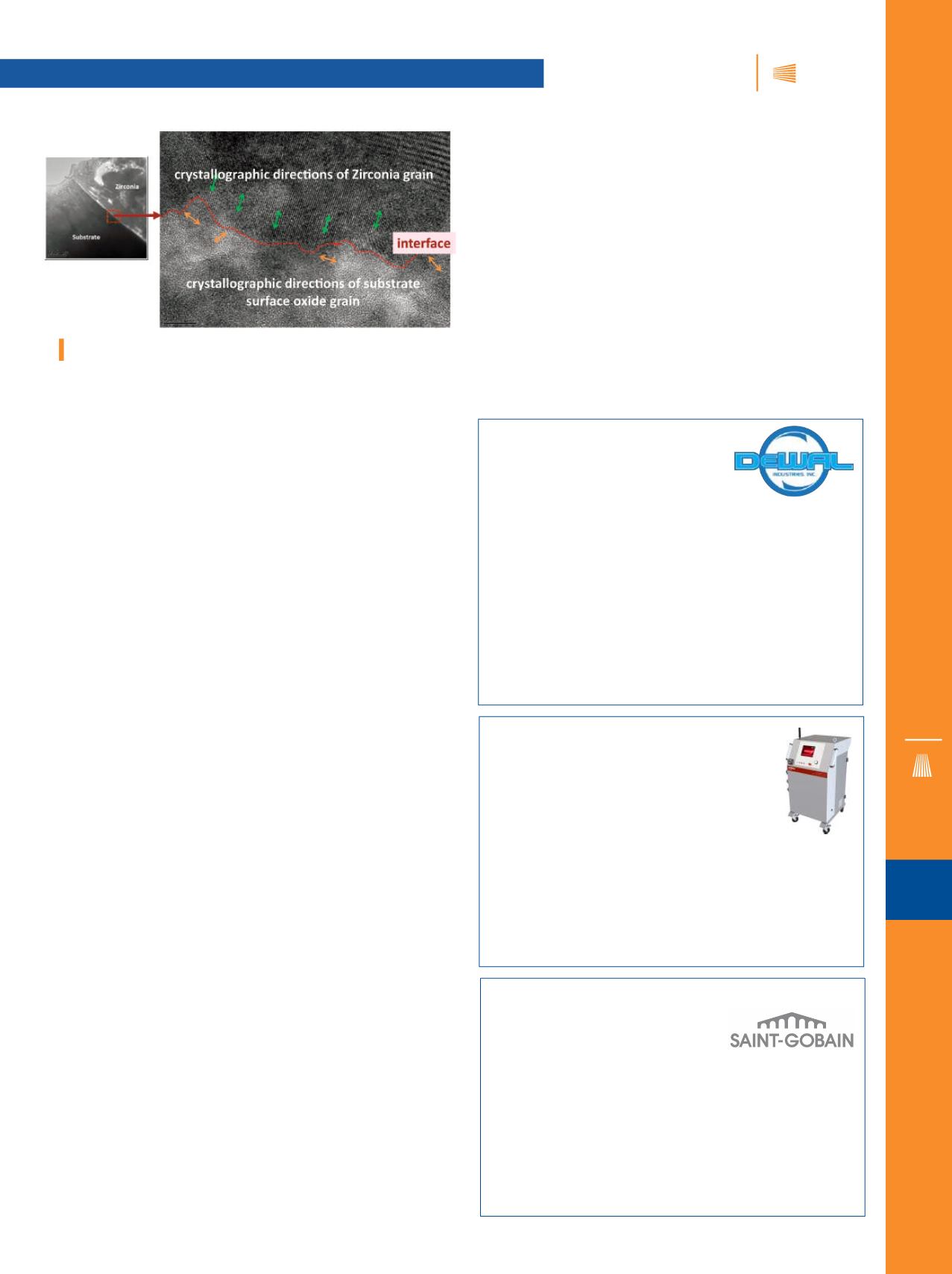

High-resolution TEM image of the ceramic/metal interface.

EXHIBITIONHOURS

Shanghai International Convention Center

Mandarin and Century Hall

Tuesday, May 10: 12:00–7:00 p.m.

Wednesday, May 11: 9:00 a.m.–5:00 p.m.

Thursday, May 12: 9:00 a.m.–2:00 p.m.

DEWAL THERMAL SPRAY TAPES DeWAL Industries manufactures the world’s most complete line of thermal spray tapes. After years developing and improving these precision plasma tapes, DeWAL manufactures them in Rhode Island for aircraft engine, automotive and medical manufacturers. DeWAL tapes are used by all three major aircraft engine manufacturers—GE, Pratt & Whitney, and Rolls-Royce. DeWAL tapes are free of carbonizing materials for grit blast, ceramic, plasma, arc, and HVOF spraying. Whatever temperature or spray angle, they adhere aggressively, ensuring sharp edges, then sep- arate cleanly. Singleanddouble-plytapes,allmanufacturedwithproprietarysil- icone adhesive technology, are availableworldwide. www.dewal.com Booth #100 OERLIKON METCO Oerlikon Metco has taken our extensive knowledge in the design of thermal spray con- trollers to provide our customers with the UniCoatPro, a feature-rich system platform for all types of spray shops. It combines simple touch- screen operation and the latest safety features with high productivity functionality such as sophisticated trending and reporting, closed-loop process control with real time monitoring, and remote maintenance capability. Choose the liquid-fuel HVOF model with a WokaJet or WokaStar gun, or the atmospheric plasma model with a traditional plasma spray gun, or the high productivity SinplexPro cascading arc gun. www.oerlikon.com/metco Booth #141 SAINT-GOBAIN COATING SOLUTIONS Saint-Gobain is a world class man- ufacturer of equipment and consumables for the thermal spray coatings industry. Our expansive equipment experience dates back to 1920 with the devel- opment of the first oxy-acteylene flame wire gun followed by Rokide® Spray Systems, Plasma Spray Systems, PTA andmany innovative ma- terials. We offer a wide range of consumables in the form of pow- der, flexible cords, Rokide® rods, and ingots for use in many different applications and industries. We supply our own raw materials and this enables us to develop a product to meet your exact needs. www.coatingsolutions.saint-gobain.com. Booth #1422016 ITSC EXHIBITOR

SHOWCASE

VISIT THESE KEY EXHIBITORS AND

MORE AT ITSC 2016

DSE-0080.1 –UniCoatPro LF Liquid-FuelHVOFController ©2014OerlikonMetco 1 ProductDataSheetUniCoatProLFLiquid-FuelHVOFControllerPlatform

Fast…Precise…Easy.UniCoatPro™ LF is the latest generationHVOF liquid-fuel controller platform fromOerlikonMetco.Combining simple operation with the latest technology and safety features in a compact cabinet, the universalUniCoatPro LF is an outstanding choice for spray shops of all sizes. 1 GeneralDescription With theUniCoatPro LF,we have takenour extensive knowl- edge in thedesignof thermal spray controllers toprovideour customerswith advanced features in a compactdesign. UniCoatPro LF employs the latest technology for safe and economicaloperation in a competitivelypriced system. Theoperator controls the entire sprayprocess via a touch screen,where easeof use is themost important consider- ation.Hotbuttonsprovidequick access to screens used fre- quently.Entryof nominal values is simple and intuitive. Thebuilt-inRemoteMaintenanceTool allowsOerlikonMetco to remotely analyze and troubleshoot the customer’s control- ler via a secure internet connection, thus reducing costly ser- vice calls anddowntime. The latest safety standards havebeen incorporated into the UniCoatPro LF spray controller.Amulti-levelmonitoring and alarm system notifies the operatorofout-of-range conditions and safely shutsdown the system in critical situations. Among theother standardUniCoatPro LF features are amul- tilingual user interface and the ability to store spray parameters. UniCoatPro LF Liquid-FuelHVOFController