iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 6

4 6

iTSSe

TSS

8

RESEARCH SPOTLIGHT

A

rmelle Vardelle, FASM, is a professor at the University

of Limoges, France. She is

co-chair of the Department

of Materials (Surface Treatments and Environment),

which trains roughly 120 engineering students in surface

and coating technologies

with an emphasis on saving ener-

gy and rawmaterials

. Her research interests include

thermal

spray and thermal plasma processes; modeling of plasma

processes and torch operation; transport and chemical rate

phenomena at high temperature; thermal spray coatings;

and green manufacturing. Vardelle has been a member of

TSS for more than 10 years and served on the TSS board

from 2009-2015. She was the lead editor of the

Journal of

Thermal Spray Technology

from 2009-2015 and is now the

chief editor. In addition, she is a

Fellow of both ASM Interna-

tional and

the International Plasma Chemistry Society.

As part of Vardelle’s research interests, she and her team

in the Laboratory of Science of Ceramic Processing and Surface

Treatments are developing thermal spray coatings for applica-

tion in fourth generation nuclear plants. This work is carried

out with CEA, the French Alternative Energies and Atomic En-

ergy Commission. France is involved in development of two

reactors, while six reactor concepts have been chosen by the

Generation IV Forum. France has decided to focus on two con-

cepts—sodium-cooled fast reactors (SFRs, reference system)

and gas-cooled fast reactors (GFRs, longer-term option). The

work with the SFR reactor is not yet finished, while the coating

systemdeveloped for theGFRhas resulted inapatentwithCEA.

GAS-COOLED FAST REACTORS

The Generation IV gas-cooled fast reactor (GFR) nuclear

system features a fast-neutron-spectrum and helium-cooled

reactor. It maximizes the usefulness of uranium resources by

breeding plutonium and can contribute to minimizing both

the quantity and radiotoxicity of nuclear waste by actinide

transmutation in a closed fuel cycle. The helium-cooled reac-

tor operates with an outlet temperature of 850°C and uses a

direct-cycle, helium turbine for electricity (42% efficiency at

850°C) and process heat for the thermochemical production

of hydrogen

[1,2]

. Challenging issues for the GFR design include

development of in-core and out-of-core materials capable

of resisting fast-neutron damage and high temperatures in

accident situations. Protective coatings are visualized to pro-

tect various parts of the system and also protect the system in

extreme cases where the functional temperature can increase

up to 1250°C and there is depressurization from 70 bars to at-

mospheric pressure.

Such coatings must withstand high temperature, de-

pressurization, and specific conditions of wear linked to ero-

sion by high-speed (about 280 m/s) helium gas flow. They

wouldbedepositedonmaterials1mmthickthatareresistant

to heat and erosion and exhibit stable mechanical proper-

ties at high temperatures, e.g., Haynes 230, a solid solution-

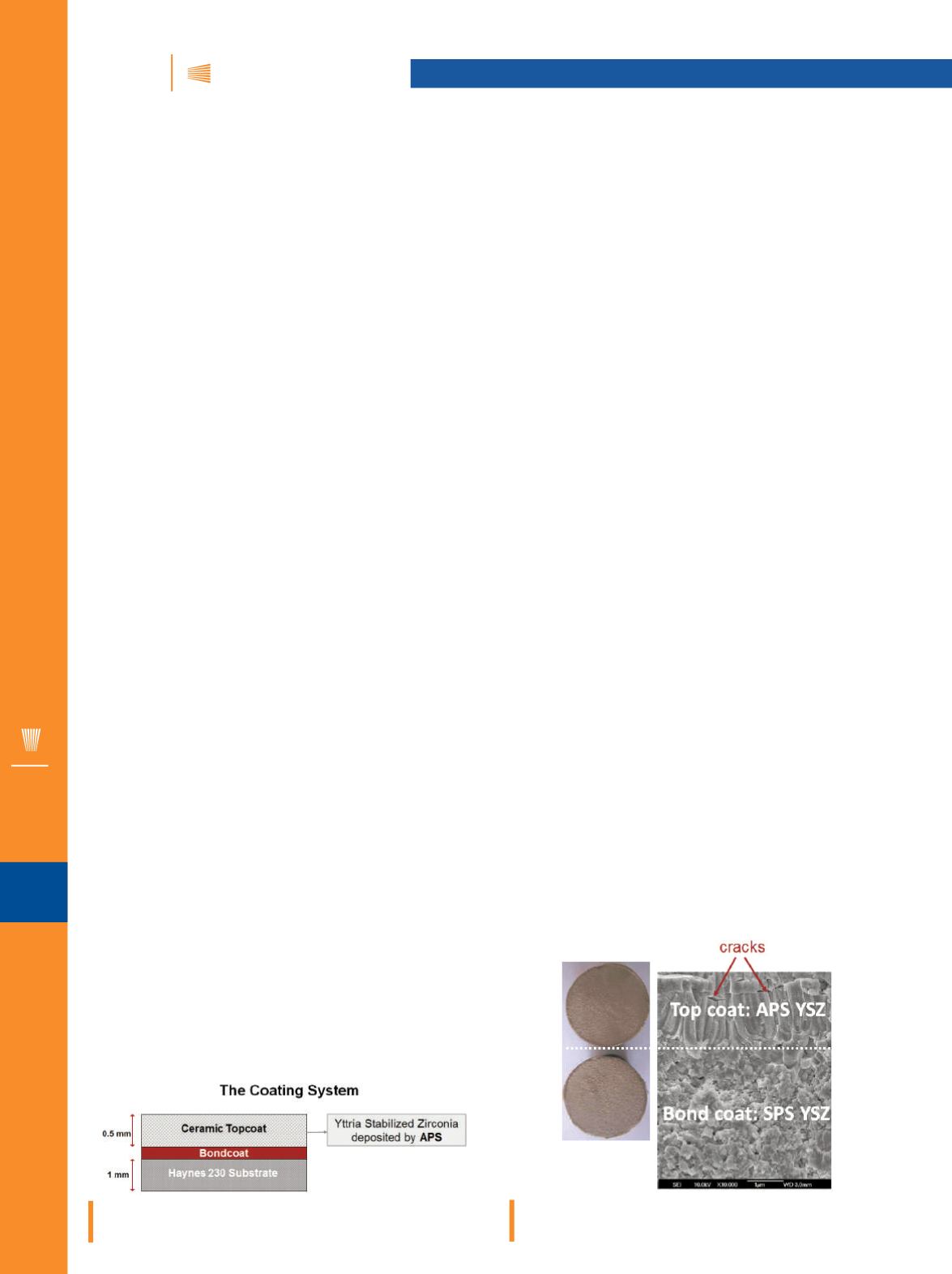

strengthened nickel-base alloy. This work involves a

double-layer plasma-sprayed zirconia coating for protecting

the out-of-core metal alloy structures against depressuriza-

tion events. The coating system consists of a thin nanostruc-

ture layer and a thick microstructure layer. The first layer

deposited by suspension plasma spraying provides adhesion

of the coating on the smooth and thin (1-mm thick) metal

(Haynes) substrate while the top layer, deposited by conven-

tional plasma spraying, acts as a thermal barrier coating.

CERAMIC COATINGS

Ceramic coatings deposited by plasma spraying are po-

tential candidates for use as protective coatings. However,

both the procedures used to prepare the substrate before

deposition and the spray process itself must be adapted to

the thinness of the substrate and its low surface roughness

(average roughness, Ra, of 0.4

µ

m). The principal objective

of surface preparation is to achieve proper adhesion of the

thermal spray coating to the substrate. The procedure gener-

ally combines abrasive blastingwith other surface preparation

techniques to create the appropriate degree of surface clean-

liness and roughness. However, roughening of the surface by

grit-blasting induces compressive stresses that bring about a

THERMAL SPRAY COATINGS FOR

NUCLEAR PLANTS

Coating systemdeposits yttria stabilized zirconia (YSZ) using

atmospheric plasma spraying (APS).

ASTM C633 tensile testing shows that the point of failure occurs

close to the interface between the ceramic layers.