iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 6

5 0

iTSSe

TSS

12

JTST

HIGHLIGHTS

The

Journal of Thermal Spray Technolo-

gy (JTST),

the official journal of the ASM

Thermal Spray Society, publishes con-

tributions on all aspects—fundamental

and practical—of thermal spray science,

including processes, feedstock manu-

facture, testing, and characterization.

As the primary vehicle for thermal spray

information transfer, its mission is to syn-

ergize the rapidly advancing thermal spray industry and relat-

ed industries by presenting research and development efforts

leading to advancements in implementable engineering appli-

cations of the technology. Articles from the February and April

issues, as selected by

JTST

Editor-in-Chief Armelle Vardelle, are

highlighted here. In addition to the print publication,

JTST

is

available online through

springerlink.com. For more informa-

tion, visit

asminternational.org/tss.“LASER PATTERNING PRETREATMENT

BEFORE THERMAL SPRAYING: A TECHNIQUE

TO ADAPT AND CONTROL THE SURFACE

TOPOGRAPHY TO THERMOMECHANICAL

LOADING AND MATERIALS”

Robin Kromer, Sophie Costil, Jonathan Cormier, Laurent

Berthe, Patrice Peyre, and Damien Courapied

Coating characteristics are highly dependent on sub-

strate preparation and spray parameters. Hence, the surface

must be adaptedmechanically andphysicochemically to favor

coating-substrate adhesion. Conventional surface preparation

methods such as grit blasting are limited by surface embrittle-

ment and produce large plastic deformations throughout the

surface, resulting in compressive stress and potential cracks.

Among all such methods, laser patterning is suitable to pre-

pare the surface of sensitive materials. No embedded grit par-

ticles canbe observed, andhigh-quality coatings are obtained.

Finally, laser surface patterning adapts the impacted surface,

creating large anchoring area. Optimized surface topogra-

phies can then be elaborated according to thematerial as well

as the application. The objective of this study is to compare

the adhesive bond strength between two surface preparation

methods, namely grit blasting and laser surface patterning,

for two material couples used in aerospace applications: 2017

aluminum alloy and AISI 304L stainless steel coated with NiAl

and YSZ, respectively. Laser patterning significantly increases

adherence values for similar contact area due to mixed-mode

(cohesive and adhesive) failure. The coating is locked in the

pattern (Fig. 1).

“THERMOELECTRIC DEVICE FABRICATION

USING THERMAL SPRAY AND LASER

MICROMACHINING”

Mahder Tewolde, Gaosheng Fu, David J. Hwang, Lei Zuo,

Sanjay Sampath, and Jon P. Longtin

Thermoelectric generators (TEGs) are solid-state devic-

es that convert heat directly into electricity. They are used in

many engineering applications such as vehicle and industrial

waste-heat recovery systems to provide electrical power, im-

prove operating efficiency, and reduce costs. State-of-the-art

TEG manufacturing is based on prefabricated materials and

a labor-intensive process involving soldering, epoxy bonding,

and mechanical clamping for assembly. This reduces their du-

rability and raises costs. Additivemanufacturing technologies,

such as thermal spray, present opportunities to overcome

these challenges. In this work, TEGs have been fabricated for

the first time using thermal spray technology and laser micro-

machining. The TEGs are fabricated directly onto engineering

component surfaces. First, current fabrication techniques of

TEGs are presented. Next, the steps required to fabricate a

thermal spray-based TEG module, including the formation of

the metallic interconnect layers and the thermoelectric legs,

are presented. A technique for bridging the air gap between

two adjacent thermoelectric elements for the top layer using

a sacrificial filler material is also demonstrated. A flat 50.8 mm

× 50.8 mm TEG module is fabricated using this method, and

its performance is experimentally characterized and found to

be in agreement with expected values of open-circuit voltage

based on the materials used (Fig. 2).

Fig. 1 —

Cohesive zone ratio computation.

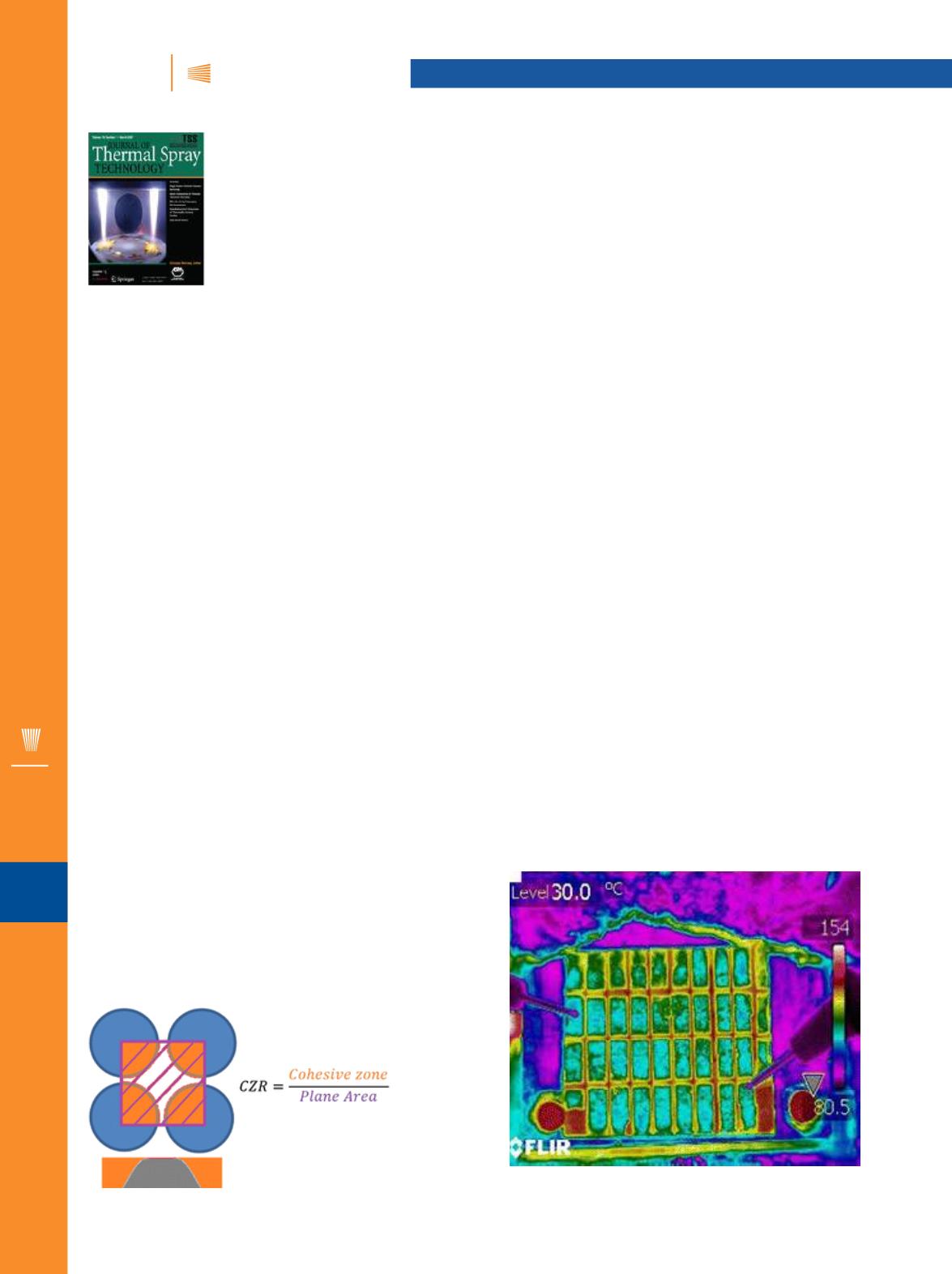

Fig. 2 —

Measurement of top-side temperature with an infrared

camera.