iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 6

5 1

JTST

HIGHLIGHTS

13

iTSSe

TSS

“HOTCORROSIONBEHAVIOROFLOW-PRESSURE

COLD-SPRAYED CoNiCrAlY COATINGS”

L.W. Zhang, X.J. Ning, L. Lu, Q.S. Wang, and L. Wang

CoNiCrAlY coatings were deposited by low-pressure cold

spraying and pre-oxidized in a vacuum environment, and its

hot corrosion behavior in pure Na

2

SO

4

and 75 wt% Na

2

SO

4

+

25 wt% NaCl salts was investigated. The pre-oxidation treat-

ment resulted in the formation of a dense and continuous

α

-Al

2

O

3

scale on the coating surface. After being corroded for

150 h at 900°C, the pre-oxidized coating exhibited better corro-

sion resistance to both salts than the as-sprayed coating. The

presence of preformed Al

2

O

3

scale reduced the consumption

rate of aluminum by delaying the formation of internal oxides

andsulfides andpromoting the formationof adenser andmore

adherent Al

2

O

3

scale. Moreover, we investigated the corrosion

mechanismof cold-sprayed CoNiCrAlY coatings in the two salts

and discussed the effect of the pre-oxidation treatment (Fig. 3).

“MICROSTRUCTURE AND MECHANICAL

PROPERTIES OF WARM-SPRAYED TITANIUM

COATING ON CARBON FIBER REINFORCED

PLASTIC”

Amirthan Ganesan, Okada Takuma, Motohiro Yamada,

and Masahiro Fukumoto

Polymer materials are increasingly dominating various

engineering fields. Recently, polymer-based composite mate-

rials’ surface performances—in particular, surfaces in relative

motion—have been improved markedly by thermal spray coat-

ing. Despite this recent progress, thedepositionof high-strength

materials—producing a coating thickness on the order of more

than500

μ

m—remainshighlychallenging. In thepresentwork, a

highly dense and thick titaniumcoatingwas successfully depos-

ited onto the carbon fiber reinforced plastic (CFRP) substrate

using a newly developed high-pressure warm spray (WS) sys-

tem. The coating properties, such as hardness (300 ± 20 HV) and

adhesion strength (8.1 ± 0.5 MPa), were evaluated and correlat-

ed with the microstructures of the coating. In addition, a wipe-

test and in situ particle velocity and temperaturemeasurement

wereperformed tovalidate theparticledepositionbehavior as a

function of the nitrogen flow rate in awarmspray system. It was

found that the microstructures, deposition efficiency (DE), and

mechanical properties of the coatings were highly sensitive to

nitrogen flowrates. The coatingporosity increasedwith increas-

ing nitrogen flow rates; however, the highest density was ob-

served for nitrogen flow rate of 1000 standard liters per minute

samples (SLM) samples due to the high fraction of semi-molten

particles in the spray stream (Fig. 5).

Fig. 3 —

Cross-sectional BSE images of as-sprayed coating.

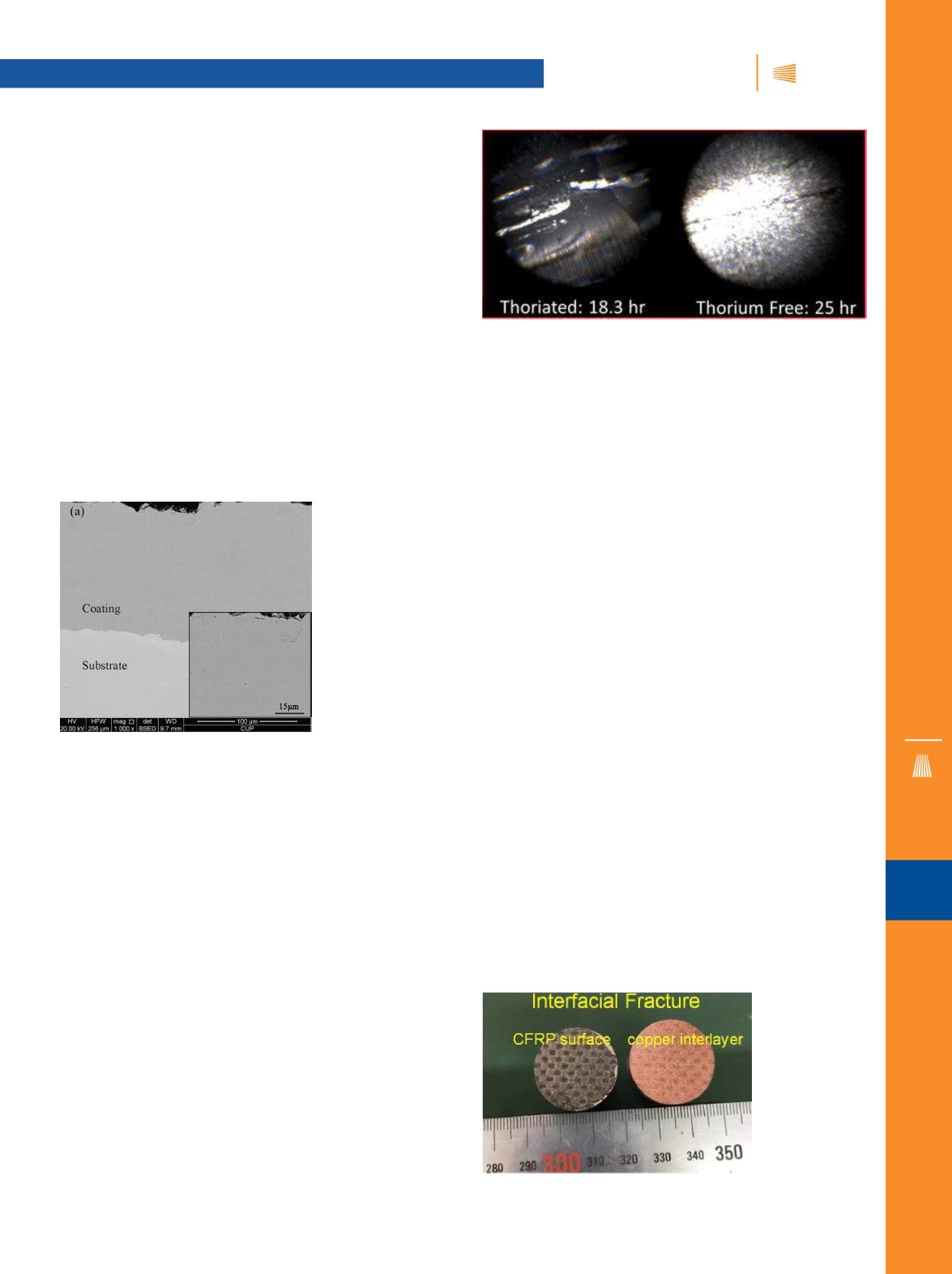

“THORIUM-FREE VERSUS THORIATED PLASMA

GUN ELECTRODES: STATISTICAL EVALUATION

OF COATING PROPERTIES”

Jose Colmenares-Angulo, Ronald Molz, David Hawley, and

Ramachandran Chidambaram Seshadri

Industries throughout the world today have an increased

awareness of environmental, health, and safety issues. This,

together with recent Nuclear Regulatory Commission changes

concerning sourcematerial (e.g., thorium) has addedcomplex-

ity in the supply chain of thoriated tungsten commonly used in

plasma spray gun spares. In the interest of a safer and more

sustainable work environment, Oerlikon Metco has developed

thorium-free material solutions proven to have longer service

life than conventional thoriated spares. This work reports on

the effect, if any, caused by tungsten compositional changes

and extended service life in coating properties. Microstructure,

coating efficiency parameters, hardness, particle state, in situ

coating stress, and ex situmodulus are evaluated over the ser-

vice life duration of the nozzle, comparing coatings with thori-

ated and non-thoriated nozzles and electrodes with the same

spray parameters (Fig. 4).

Fig. 4 —

Borescope image comparison of thoriated and

thorium-free nozzles after testing.

Fig. 5 —

Fracture surface of adhesion

strength samples

.