A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 6

1 4

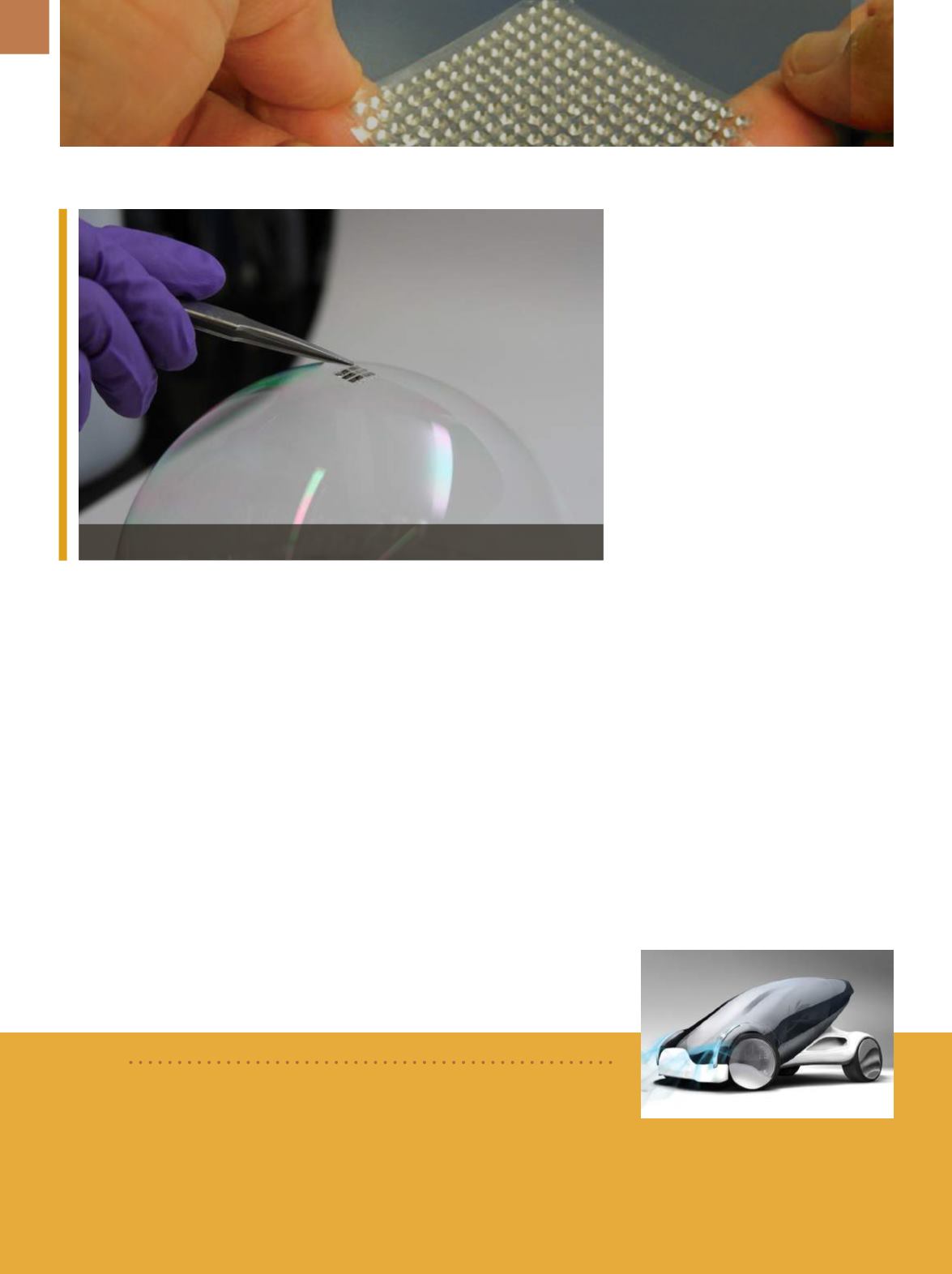

ULTRATHIN SOLAR CELLS

GROWN IN A VACUUM

Researchers at Massachusetts In-

stitute of Technology, Cambridge, de-

veloped a novel approach to solar cell

production that resulted in the thinnest,

lightest photovoltaic cell ever made—a

cell so lightweight and flexible, it can

be draped on a soap bubble without

popping it. Key to the new approach

is making the solar cell, substrate, and

protective coating in one process. Un-

like current solar cell construction prac-

tices, the entire procedure takes place

in a vacuum chamber at room tempera-

ture and does not involve solvents.

In their proof-of-concept cell, re-

searchers use a glass carrier—the flexi-

ble polymer parylene—as both the sub-

strate and overcoating. An organic

material called DBP serves as the

primary light-absorbing layer. Both the

substrate and solar cell were grown us-

ing established vapor deposition tech-

niques. After construction, the entire

parylene/solar cell/parylene stack was

peeled off the carrier with a frame of

flexible film. The final cells are about

2 µm thick—just one-thousandth the

thickness of equivalent cells on glass

substrates—but they are just as effi-

cient, and their power-to-weight ratio

is reportedly among the highest ever

achieved. Whereas a typical silicon-

base solar module may produce about

15 W per kilogram, the new cells have

an output of 6 W per gram—about 400

times higher.

mit.edu.

DOE ESTABLISHES

MATERIALS NETWORK

The U.S. Department of Energy

launched its Energy Materials Network

Ultrathin solar cell rests atop a soap bubble. Courtesy of Joel Jean and Anna Osherov.

BRIEF

The Global Climate and Energy Project (GCEP) at Stanford University,

Calif.,

awarded $7.6 million to research teams at their university and three others to

support work on advanced energy technologies for industrialized countries

and the developing world. Among the recipients is Reinhold Dauskardt, a

Stanford professor of materials science and engineering, whose team will work

on transportation vehicle lightweighting with polymeric glazing and moldings.

The team will use a novel glazing process to create lightweight polymer materi-

als to replace conventional glass windows and metal frames.

stanford.edu.

ENERGY TRENDS

(EMN), a National Laboratory-led ini-

tiative that will address one of the

major challenges to widespread com-

mercialization of clean energy tech-

nologies—the design, testing, and

production of advanced materials. The

$40 million effort, funded by DOE’s

Office of Energy Efficiency and Renew-

able Energy, will facilitate collaboration

between National Labs, industry, and

academia as it solicits proposals for

joint R&D projects and establishes four

initial consortia to focus on specific

classes of materials.

For example, the Lightweight Ma-

terials Consortium (LightMat), led by

Pacific Northwest National Laboratory,

Richland, Wash., will design special-

ized alloys and carbon fiber reinforced

polymer composites that can be man-

ufactured on a large scale; the Elec-

trocatalysis Consortium (ElectroCat),

led by Argonne National Laboratory,

Lemont, Ill., and Los Alamos National

Laboratory, N.M., will seek more abun-

dant and inexpensive alternatives to

the platinum group metals currently

used in hydrogen fuel cells; and the Ca-

loric Cooling Consortium (CaloriCool),

led by Ames Laboratory, Iowa, will

seek to develop, demonstrate, and de-

ploy “caloric” refrigerant materials that

could increase cooling efficiency

. energy. gov/eere/energy-materials-network/ energy-materials-network.Reinhold Dauskardt is developing a

technology to enable use of lightweight

polymers in aerodynamic vehicles.

Courtesy of Antii Eskeli.