A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 6

1 3

CORPORATE SPOTLIGHT

The use of modelling and simulation tools in materials

R&D is growing rapidly as highlighted by the publication from

the National Academies on Integrated Computational Materi-

als Engineering (ICME) in 2008, and the announcement of the

Materials Genome Initiative (MGI) in 2011.

As a leading developer of software and databases for cal-

culations involving computational thermodynamics and diffu-

sion controlled simulations, Thermo-Calc Software is a foun-

dational component of any ICME/MGI framework. For more

than 30 years, Thermo-Calc has been used within industry,

government research labs and academia to gain insight into

problems related to materials science and engineering and is

now licensed by more than 1,000 of the world’s top companies,

research labs and universities in over 70 countries.

SOFTWARE

In addition to our primary software package, Thermo-Calc

users can select add-on packages that extend the functionality

of the software.

Thermo-Calc

: a powerful tool for performing thermody-

namic and phase equilibria calculations for multicompo-

nent systems.

DICTRA

: an add-on program used for accurate simula-

tions of diffusion in multicomponent alloys.

TC-PRISMA

: an add-on program for the prediction of

precipitation kinetics.

Software developments kits

: enable Thermo-Calc to

be called directly from the user’s own software or from

MATLAB.

More information on these products can be found on our

website, www.thermocalc.com.

DATABASES

Calculations are based on thermodynamic

and mobility databases produced by expert

evaluation of experimental data using the

CALPHAD approach. More than 30 thermo-

dynamic databases are available which

cover a broad range of materials and sys-

tems including Fe-based alloys, Ni-, Al-,

Mg-, Ti- alloys, solders, oxides and slags,

aqueous systems and more. Detailed in-

formation on these databases is available

on our website, www.thermocalc.com.

Our modelling and simulation tools are

used for many different purposes within the lifecy-

cle of a material, from R&D efforts in designing new ma-

terials to identifying optimal processing windows, all the way

through addressing waste and re-cycling issues. Typical bene-

fits expressed by our customers include:

•

Reducing the number of costly, time-consuming

experiments and testing by making better use of

pre-screening/pre-test calculations

•

Increasing the value of experiments through deeper

understanding of the results

•

Defining safe and optimal processing windows in

terms of composition tolerances and temperatures

•

Basing decisions on scientifically supported models,

tools and data

•

Shortening development times and bringing products

to market faster

•

Making predictions that are difficult or even impossi-

ble with an experimental approach

REGULAR UPDATES AND SUPPORT

Originally developed in the early 1980s, Thermo-Calc has

been consistently updated to satisfy the needs of our

customers. Our software are now on a two times

per year release cycle, and our main databases

are also updated regularly.

Our products are

backed by a dedi-

cated technical support team that helps

our users get the most from our tools.

With representatives in 9 countries

around the world and a subsidiary in the

United States, local support is available in

many regions. Training courses are held two

times per year in Sweden and the USA as well

as other locations in conjunction with our agents.

THERMO-CALC SOFTWARE

Thermo-Calc Software

email: paul@thermocalc.com • web: www.thermocalc.com

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 6

1 3

CORPORATE SPOTLIGHT

The use of modelling and simulation tools in materials

R&D is growing rapidly as highlighted by the publication from

the National Academies on Integrated Computational Materi-

als Engineering (ICME) in 2008, and the announcement of the

Materials Genome Initiative (MGI) in 2011.

As a leading developer of software and databases for cal-

culations involving computational thermodynamics and diffu-

sion controlled simulations, Thermo-Calc Software is a foun-

dational component of any ICME/MGI framework. For more

than 30 years, Thermo-Calc has been used within industry,

government research labs and academia to gain insight into

problems related to materials science and engineering and is

now licensed by more than 1,000 of the world’s top companies,

research labs and universities in over 70 countries.

SOFTWARE

In addition to our primary software package, Thermo-Calc

users can select add-on packages that extend the functionality

of the software.

Thermo-Calc

: a powerful tool for performing thermody-

namic and phase equilibria calculations for multicompo-

nent systems.

DICTRA

: an add-on program used for accurate simula-

tions of diffusion in multicomponent alloys.

TC-PRISMA

: an add-on program for the prediction of

precipitation kinetics.

Software developments kits

: enable Thermo-Calc to

be called directly from the user’s own software or from

MATLAB.

More information on these products can be found on our

website, www.thermocalc.com.

DATABASES

Calculations are based on thermodynamic

and mobility databases produced by expert

evaluation of experimental data using the

CALPHAD approach. More than 30 thermo-

dynamic databases are available which

cover a broad range of materials and sys-

tems including Fe-based alloys, Ni-, Al-,

Mg-, Ti- alloys, solders, oxides and slags,

aqueous systems and more. Detailed in-

formation on these databases is available

on our website, www.thermocalc.com.

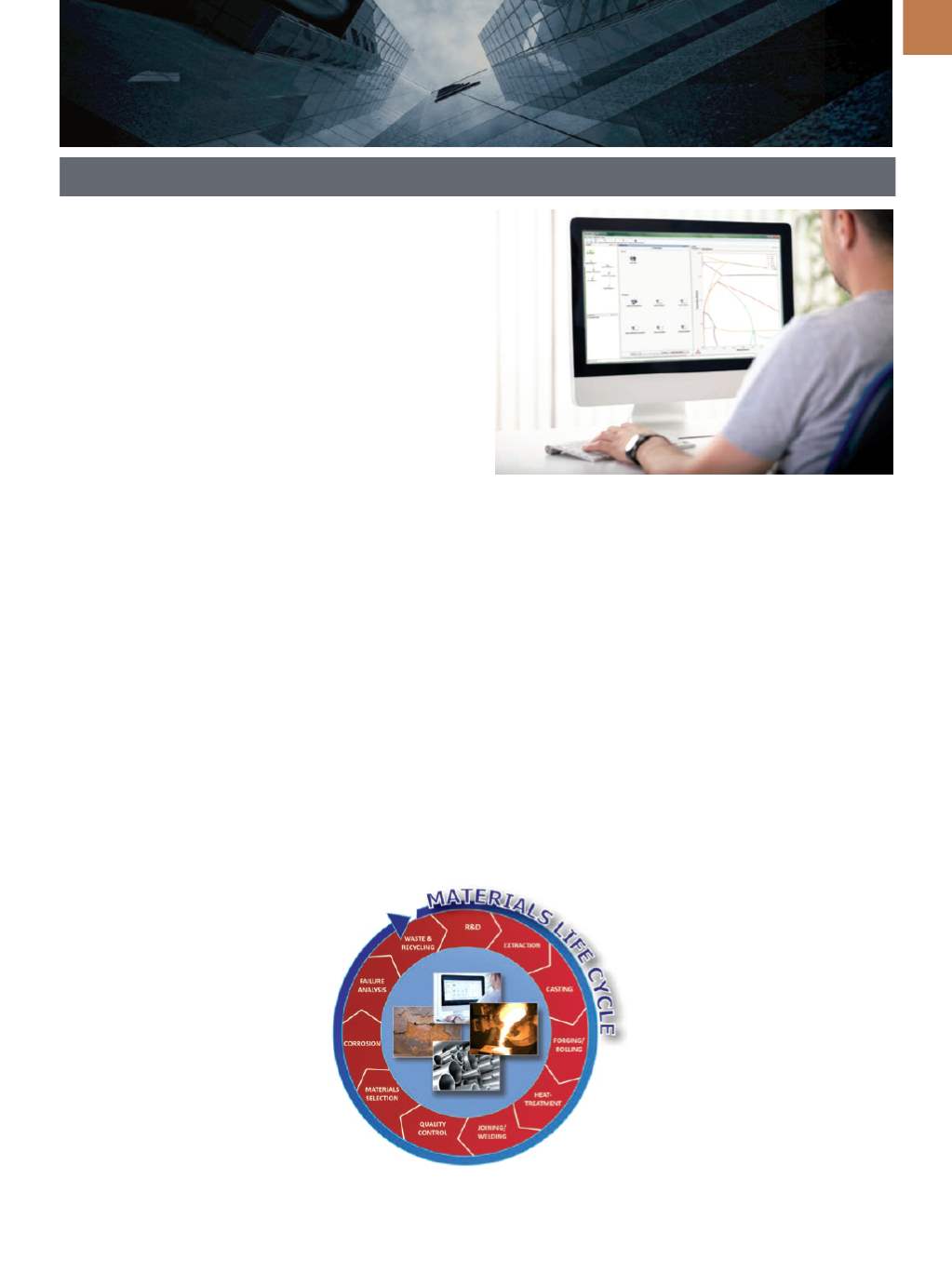

Our modelling and simulation tools are

used for many different purposes within the lifecy-

cle of a material, from R&D efforts in designing new ma-

terials to identifying optimal processing windows, all the way

through addressing waste and re-cycling issues. Typical bene-

fits expressed by our customers include:

•

Reducing the number of costly, time-consuming

experiments and testing by making better use of

pre-screening/pre-test calculations

•

Increasing the value of experiments through deeper

understanding of the results

•

Defining safe and optimal processing windows in

terms of composition tolerances and temperatures

•

Basing decisions on scientifically supported models,

tools and data

•

Shortening development times and bringing products

to market faster

•

Making predictions that are difficult or even impossi-

ble with an experimental approach

REGULAR UPDATES AND SUPPORT

Originally developed in the early 1980s, Thermo-Calc has

been consistently updated to satisfy the needs of our

customers. Our software are now on a two times

per year release cycle, and our main databases

are also updated regularly.

Our products are

backed by a dedi-

cated technical support team that helps

our users get the most from our tools.

With representatives in 9 countries

around the world and a subsidiary in the

United States, local support is available in

many regions. Training courses are held two

times per year in Sweden and the USA as well

as other locations in conjunction with our agents.

THERMO-CALC SOFTWARE

Thermo-Calc Software

email: paul@thermocalc.com • web: www.thermocalc.com

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 6

1 3

CORPORATE SPOTLIGHT

The use of modelling and simulation tools in materials

R&D is growing rapidly as highlighted by the publication from

the National Academies on Integrated Computational Materi-

als Engineering (ICME) in 2008, and the announcement of the

Materials Genome Initiative (MGI) in 2011.

As a leading developer of software and databases for cal-

culations involving computational thermodynamics and diffu-

sion controlled simulations, Thermo-Calc Software is a foun-

dational component of any ICME/MGI framework. For more

than 30 years, Thermo-Calc has been used within industry,

government research labs and academia to gain insight into

problems related to materials science and engineering and is

now licensed by more than 1,000 of the world’s top companies,

research labs and universities in over 70 countries.

SOFTWARE

In addition to our primary software package, Thermo-Calc

users can select add-on packages that extend the functionality

of the software.

Thermo-Calc

: a powerful tool for performing thermody-

namic and phase equilibria calculations for multicompo-

nent systems.

DICTRA

: an add-on program used for accurate simula-

tions of diffusion in multicomponent alloys.

TC-PRISMA

: an add-on program for the prediction of

precipitation kinetics.

Software developments kits

: enable Thermo-Calc to

be called directly from the user’s own software or from

MATLAB.

More information on these products can be found on our

website, www.thermocalc.com.

DATABASES

Calculations are based on thermodynamic

and mobility databases produced by expert

evaluation of experimental data using the

CALPHAD approach. More than 30 thermo-

dynamic databases are available which

cover a broad range of materials and sys-

tems including Fe-based alloys, Ni-, Al-,

Mg-, Ti- alloys, solders, oxides and slags,

aqueous systems and more. Detailed in-

formation on these databases is available

on our website, www.thermocalc.com.

Our modelling and simulation tools are

used for many different purposes within the lifecy-

cle of a material, from R&D efforts in designing new ma-

terials to identifying optimal processing windows, all the way

through addressing waste and re-cycling issues. Typical bene-

fits expressed by our customers include:

•

Reducing the number of costly, time-consuming

experiments and testing by making better use of

pre-screening/pre-test calculations

•

Increasing the value of experiments through deeper

understanding of the results

•

Defining safe and optimal processing windows in

terms of composition tolerances and temperatures

•

Basing decisions on scientifically supported models,

tools and data

•

Shortening development times and bringing products

to market faster

•

Making predictions that are difficult or even impossi-

ble with an experimental approach

REGULAR UPDATES AND SUPPORT

Originally developed in the early 1980s, Thermo-Calc has

been consistently updated to satisfy the needs of our

customers. Our software are now on a two times

per year release cycle, and our main databases

are also updated regularly.

Our products are

backed by a dedi-

cated technical support team that helps

our users get the most from our tools.

With representatives in 9 countries

around the world and a subsidiary in the

United States, local support is available in

many regions. Training courses are held two

times per year in Sweden and the USA as well

as other locations in conjunction with our agents.

THERMO-CALC SOFTWARE

Thermo-Calc Software

email: paul@thermocalc.com • web: www.thermocalc.com

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 6

1 3

CORPORATE SPOTLIGHT

The use of modelling and simulation tools in materials

R&D is growing rapidly as highlighted by the publication from

the National Academies on Integrated Computational Materi-

als Engineering (ICME) in 2008, and the announcement of the

Materials Genome Initiative (MGI) in 2011.

As a leading developer of software and databases for cal-

culations involving computational thermodynamics and diffu-

sion controlled simulations, Thermo-Calc Software is a foun-

dational component of any ICME/MGI framework. For more

than 30 years, Thermo-Calc has been used within industry,

government research labs and academia to gain insight into

problems related to materials science and engineering and is

now licensed by more than 1,000 of the world’s top companies,

research labs and universities in over 70 countries.

SOFTWARE

In addition to our primary software package, Thermo-Calc

users can select add-on packages that extend the functionality

of the software.

Thermo-Calc

: a powerful tool for performing thermody-

namic and phase equilibria calculations for multicompo-

nent systems.

DICTRA

: an add-on program used for accurate simula-

tions of diffusion in multicomponent alloys.

TC-PRISMA

: an add-on program for the prediction of

precipitation kinetics.

Software developments kits

: enable Thermo-Calc to

be called directly from the user’s own software or from

MATLAB.

More information on these products can be found on our

website, www.thermocalc.com.

DATABASES

Calculations are based on thermodynamic

and mobility databases produced by expert

evaluation of experimental data using the

CALPHAD approach. More than 30 thermo-

dynamic databases are available which

cover a broad range of materials and sys-

tems including Fe-based alloys, Ni-, Al-,

Mg-, Ti- alloys, solders, oxides and slags,

aqueous systems and more. Detailed in-

formation on these databases is available

on our website, www.thermocalc.com.

Our modelling and simulation tools are

used for many different purposes within the lifecy-

cle of a material, from R&D efforts in designing new ma-

terials to identifying optimal processing windows, all the way

through addressing waste and re-cycling issues. Typical bene-

fits expressed by our customers include:

•

Reducing the number of costly, time-consuming

experiments and testing by making better use of

pre-screening/pre-test calculations

•

Increasing the value of experiments through deeper

understanding of the results

•

Defining safe and optimal processing windows in

terms of composition tolerances and temperatures

•

Basing decisions on scientifically supported models,

tools and data

•

Shortening development times and bringing products

to market faster

•

Making predictions that are difficult or even impossi-

ble with an experimental approach

REGULAR UPDATES AND SUPPORT

Originally developed in the early 1980s, Thermo-Calc has

been consistently updated to satisfy the needs of our

customers. Our software are now on a two times

per year release cycle, and our main databases

are also updated regularly.

Our products are

backed by a dedi-

cated technical support team that helps

our users get the most from our tools.

With representatives in 9 countries

around the world and a subsidiary in the

United States, local support is available in

many regions. Training courses are held two

times per year in Sweden and the USA as well

as other locations in conjunction with our agents.

THERMO-CALC SOFTWARE

Thermo-Calc Software

email: paul@thermocalc.com • web: www.thermocalc.com