A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

S E P T E M B E R

2 0 1 5

2 5

a stream of gas in a two-story chamber,

resulting in spherical particles. Helium,

argon, and ultimately nitrogen were

all used as atomization gases. An SEM

micrograph of atomized Be powder is

shown in Fig. 7.

Spherical particles pack together

with no relation to crystal orientation.

Because each particle is randomly ori-

ented, no large regions can develop.

Properties level themselves out, lead-

ing to an essentially uniform surface.

In conjunction with HIP consolidation,

this results in a predictable mirror

with equal thermal contraction in all

directions. In addition, oxide particles

degrade the performance of a mirror

because each oxide particle acts as a

separate scattering source. Therefore,

lower oxide translates into improved

optical performance. The solid optical

blanks made from the atomized optical

grade of beryllium powder, O-30, have

less than 0.35% beryllium oxide. Recall

that I-70A and S-200F have 0.7% and

1% oxide respectively. Atomized pow-

der is therefore an excellent choice for

a mirror material

[7]

.

Once the powder is made, it is

compacted into a solid. Historically,

powder was vacuum hot pressed into

solid cylinders ranging from roughly

8 to 72 inches in diameter. Aerospace

components requiring the highest level

of stiffness to density were made from

these cylinders. For example, the Space

Shuttle umbilical doors were machined

from large-diameter hot pressed cyl-

inders, as were the window frame,

brakes, and navigation base. The

Advanced Inertial Reference Spheres

(AIRS) of the Peacekeeper ICBM (inter-

continental ballistic missile) were

likewise machined from vacuum hot

pressed beryllium. This hot pressing

method leaves less than 0.5% voids,

but does not totally eliminate them.

For the JWST Telescope, all voids had

to be eliminated, leading to use of hot

isostatic pressing (HIP)

[2]

.

Although HIP was developed by

Battelle at its Columbus, Ohio, head-

quarters in the 1940s for cladding nu-

clear reactor fuel rods, its uses have

greatly expanded to include casting

densification, powder consolidation,

and diffusion bonding. In HIP, powder

is poured into a metal can that is evacu-

ated and sealed. This is then placed into

the HIP unit, which is pressurized with

argon and heated. A typical pressure

compressing the can and its contents is

15,000 to 30,000 psi and temperatures

to 2000°C can be applied. The solid

that emerges after the can is removed

is completely free of voids. Another ad-

vantage of HIP is that the pressure is ap-

plied in all directions so it maintains the

non-directionality of the final product

better than uniaxial vacuum hot press-

ing. The microstructure of consolidated

O-30 is shown in Fig. 8.

Technologists who worked on mir-

rors in the 1960s reported that beryllium

atomization trials were unsuccessful. In

particular,veryhighoxidelevelsresulted.

Much effort was spent making certain

that the new atomizer was airtight to

control the oxygen level. HIP’ing beryl-

lium powder had also been tried, but

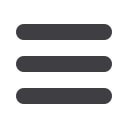

failed because voids were formed when

Discover More Steel Research Capability www.tainstruments.com DIL 805 Quenching and Deformation Dilatometer The DIL 805-series quenching and deformation dilatometers provide the most accurate measurements over the widest range of heating, cooling,anddeformationconditions,allowingforthemostsophisticated characterization and optimization of steel processing conditions. The DIL 805 provides critical data for the construction of time-temperature- transformation (TTT) , continuous-cooling-transformation (CCT) , and time-temperature-transformation after deformation (DTTT) diagrams as well as stress-strain curves. Powerful inductive heating and an innovative helium quench system enable heating rates up to 4000 K/s and quenching rates as high as 2500 K/s to capture the extremes of modern processing conditions.