A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

S E P T E M B E R

2 0 1 5

2 1

L

aunching objects into earth’s orbit

is enormously expensive, so every

pound removed saves significant

cost. When considering materials for the

James Webb Space Telescope (JWST), a

lengthy competition took place to deter-

mine the best choices and beryllium was

ultimately specified for the mirrors. This

article documents the developmental

history leading up to that decision. It took

decades of improvements to make Be—

in particular O-30 atomized powder/

hot isostatically pressed (HIP’d) compo-

nents—homogeneous, isotropic, polish-

able, thermally and dimensionally stable,

and above all, predictable.

BERYLLIUM PROPERTIES:

IDEAL FOR SPACE

The most obvious requirements

for space optics include low mass, high

stiffness, predictable contraction when

cooled to cryogenic temperatures, and

the ability to be polished to a highly

reflective surface. These characteris-

tics were recognized and discussed

as design parameters as early as 1966

by Barnes

[1]

, while limitations of the

available vacuum hot pressed (VHP)

Be were also detailed. A decade later,

after numerous telescopes with Be mir-

rors were already in orbit, hot isostatic

pressing was advocated for Be optics

and an evaluation of HIP’d Be material

in comparison with VHP’d Be from the

same powder was published

[2]

. The new

material was found to be superior and

therefore meets the specifications for

infrared mirrors.

Low thermal expansion glass,

such as the ULE fused silica (Corning’s

Code 7972 Ultra Low Expansion Glass)

selected for the Hubble Space Tele-

scope primary mirror, meets several of

the material criteria very reliably—but

not as well as O-30 Be, which was devel-

oped specifically for satellite mirrors.

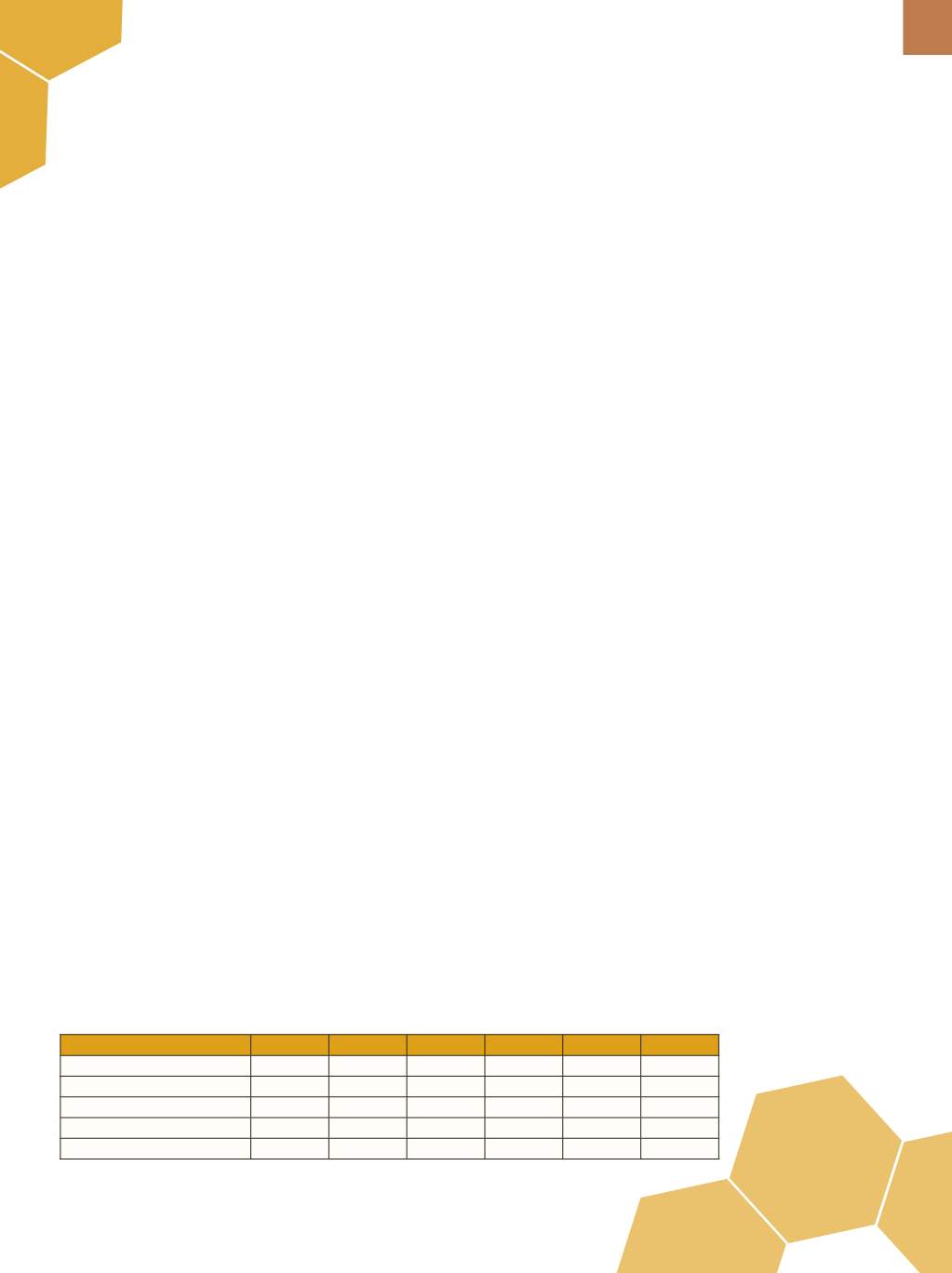

Table 1 compares the important prop-

erties of O-30 Be, ULE, aluminum, and

magnesium.

In order to minimize mass, using a

low density material is an obvious first

step: The density of ULE is slightly less

than that of Al. However, conventional

mirror materials such as ULE and Al are

much heavier than Be, which is 31%

lighter than Al and 18% lighter than

ULE. Magnesium is 6% lighter than

Be. Yet another factor is stiffness, or

modulus of elasticity, which is equally

important because it measures how

well a material resists deformation

under load. Beryllium is 400% stiffer

than both Al and ULE and 670% stiffer

than Mg. Specific stiffness—the ratio of

modulus to density—determines the

engineering efficiency of a material,

and it is clear that Be is more than five

times better than the other materials in

this regard.

Specific stiffness measures how

well a structure maintains its shape

in the face of forces such as gravity,

launch, or maneuvering g’s. After a

mirror is polished to its desired shape—

or

optical figure

—on earth at 1 g, it

changes figure in the 0-g orbital envi-

ronment. This “gravity release” causes

only a slight figure change, but with

very lightweight mirrors these changes,

measured in fractions of wavelengths

of light, can be enough to substantially

distort the image. Grinding and pol-

ishing the mirror on earth to what will

become the correct figure in space is

called

null figuring,

which is much eas-

ier with a material featuring a high spe-

cific stiffness because the distortions

are so much smaller. Surprisingly, steel,

Al, Ni alloys, and Ti alloys all have sim-

ilar ratios to Mg and ULE, while the

specific stiffness of Be surpasses all of

these, as shown in Table 1.

Historically, Be was not considered

an ideal optical material

[1]

. However,

due to its significant weight and stiff-

ness advantages, a concentrated devel-

opment effort worked to overcome its

limitations. During the 1980s, the Stra-

tegic Defense Initiative emphasized the

need for extremely lightweight, high

performance surveillance satellites. It

was during the “Star Wars” initiative

that the shortcomings of Be as a mirror

material were generally recognized and

possible solutions imagined. Designers

of satellite mirrors and structures con-

stantly thought about how to save even

a single pound. Beryllium affords these

designers the opportunity to poten-

tially save hundreds of pounds.

BERYLLIUM SPACE

TELESCOPE HISTORY

The reflecting mirrors that act as

the compound eyes of the James Webb

Space Telescope are among the most

precise and complex space optics ever

fabricated. Essential to the telescope’s

performance are the characteristics of

18 adjustable segments that make up

the 6.5-m primary reflector. Specifying

Be broke new ground in high perfor-

mance space optical materials develop-

ment, and was a significant departure

from the glass Hubble Space Telescope

primary mirror that preceded the JWST.

However, even during the 1970s, many

space telescopes featured Be optics.

These early mirrors cleared the path to

the improved polishability and stability

of the JWST.

TABLE 1 —ROOM TEMPERATURE PROPERTIES OF MIRROR MATERIALS

Property

Symbol

Units O-30 Be ULE 6061 Al

Mg

Density

ρ

g/cm

3

1.85

2.21

2.70

1.74

Modulus

E

GPa

303

68

68

45

Specific stiffness

E/

ρ

10

6

m

2

/s

2

163

30

25

26

Coeff. of thermal expansion

α

10

-6

/K

11.4

0.03

22.5

24.8

Thermal conductivity

k

W/m•K

208

1.3

167

156