A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

S E P T E M B E R

2 0 1 5

2 3

observatories. With its 85-cm diameter,

bare polished primary mirror made of

HIP consolidated I-70 Be (I-70H), this

all-Be telescope operates at 5.5K. An

SEM and associated light micrograph

of I-70H are shown in Figs. 3 and 4. The

telescope shown in Fig. 5 is the proto-

type being tested at Jet Propulsion Lab-

oratory

[5]

. The excellent surface finish

and optical figure obtained, as well as

the insignificant thermal dimensional

instability observed when tested at 10K,

were a direct result of the improved

material quality achieved by the HIP

process. Because the optical figure of

the primary mirror was tested at cryo-

genic temperatures, the correction to

the small figure error was polished into

the surface in a process called cryo null

figuring. While neither the scatter nor

optical figure of this telescope would

be acceptable for a diffraction limited

visible wavelength system, it exceeded

specifications for the mid and far infra-

red wavelengths being observed.

The low oxide content and resid-

ual inhomogeneity found in I-70H (0.7%

BeO) needed to be reduced even fur-

ther before Be could become a viable

candidate for JWST mirrors, because

they operate at much shorter wave-

lengths. The next step—development

of spherical Be powder consolidated by

HIP—provided the ultimate material for

the JWST mirrors. Four mirrors are used

in the JWST, including the 18 segment

6.5-m primary, 738-mm secondary,

738 x 517-mm tertiary, and a 172.5-mm

fast steering mirror to stabilize the

image. All mirrors are gold-coated for

enhanced infrared reflectance. Figure 6

shows the finished mirrors and the com-

plete JWST

[6]

.

Each of the 18 primary mirror seg-

ments (plus spares) measures 1.3 m and

weighs approximately 40 kg (88 lb). Seg-

ments were polished to a surface figure

accuracy of 24.2 nm rms and include

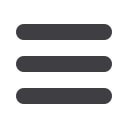

Fig. 1 —

500× SEM photomicrograph of S-200F grade blocky shaped

berylliumpowder produced by impact grinding. All images courtesy of

Materion except 5 and 6.

Fig. 2 —

Polarized light photomicrograph of S-200F grade beryllium.

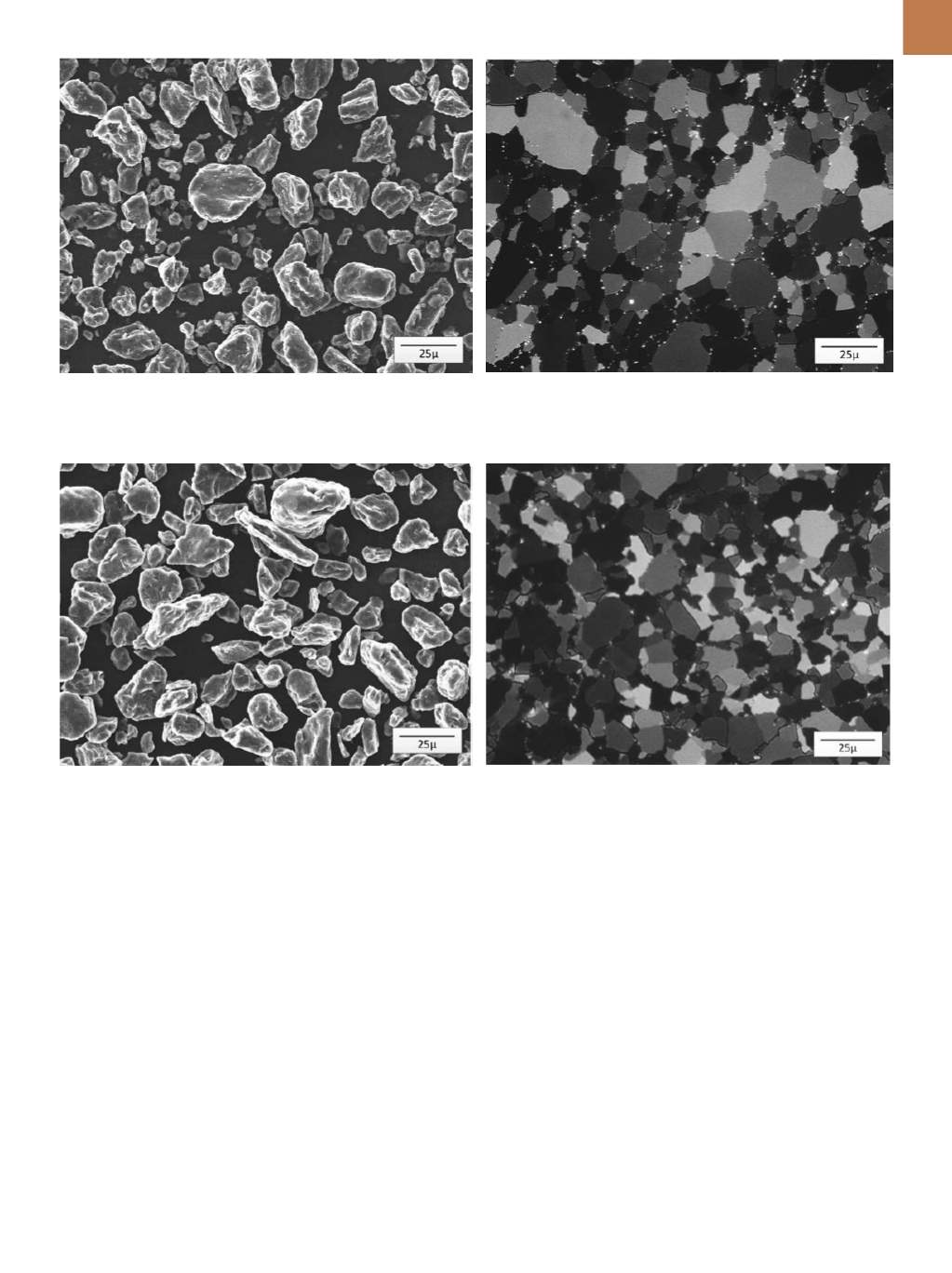

Fig. 3 —

SEM photomicrograph of I-70 grade berylliumpowder pro-

duced to a higher purity in comparison to S-200F grade that improved

the ability to produce a polishedmirror surface. Powder is produced by

impact grinding.

Fig. 4 —

Polarized light photomicrograph of I-70H grade of beryllium

consolidated by HIP. Higher purity input powder in comparison to

S-200F is illustrated by fewer white oxide particles.