A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

S E P T E M B E R

2 0 1 5

3 1

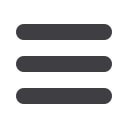

TABLE 3—RELATIVE INTENSITIES OF TA 4F OXIDE AND REDUCED

COMPONENTS BEFORE AND AFTER SPUTTER-CLEANING

Cleaning method

Ta 4f oxide Ta 4f reduced

None

100

-

Cluster ions

100

-

200eV monatomic

70.4

29.6

TABLE 2—ATOMIC CONCENTRATIONS BEFORE

AND AFTER CLUSTER-CLEANING

Name

As-received

atomic %

After cluster

cleaning atomic %

C

50.7

0

O

33.7

71.8

Ta

11.8

28.2

Si

3.8

0

Fig. 4 —

Comparison of Ta 4f spectra for monatomic Ar

+

and

argon cluster ion sputter-cleaning of Ta

2

O

5

.

Fig. 3 —

Comparison of XPS survey spectra before and after argon cluster

ion cleaning.

Hackensack, NJ 07601, USA +1.201.343.8983 main masterbond.com www.masterbond.com ONE COMPONENT, NON-DRIP ADHESIVE for STRUCTURAL BONDING TEMPERATURE RANGE Serviceable from -60°F to +500°F EPOXY SYSTEM STRENGTH PROFILE Tensile strength, 75°F >8,000 psi Compressive strength, 75°F >18,000 psi ELECTRICAL INSULATION Volume resistivity, 75°F >10 14 ohm-cm