ADVANCED MATERIALS & PROCESSES •

NOVEMBER-DECEMBER 2014

60

i

T

S

S

e

10

JTST HIGHL IGHTS

The

Journal of Thermal Spray Technology

(JTST),

the official journal of the ASM

Thermal Spray Society, publishes contri-

butions on all aspects—fundamental and

practical—of thermal spray science, in-

cluding processes, feedstock manufacture,

testing, and characterization. As the pri-

mary vehicle for thermal spray information

transfer, its mission is to synergize the rap-

idly advancing thermal spray industry and

related industries by presenting research

and development efforts leading to advancements in imple-

mentable engineering applications of the technology. Articles

from the October and December issues, as selected by

JTST

Editor-in-Chief Christian Moreau, are highlighted here. The

October issue is a special issue on “Nanocomposite Coatings,”

organized by guest editors Rehan Ahmed and Christopher

Berndt. The first two articles highlighted below are from this

special issue. In addition to the print publication,

JTST

is avail-

able online through

springerlink.com. For more information,

visit

asminternational.org/tss.“Nanostructural Characteristics

of Vacuum Cold-Sprayed

Hydroxyapatite/Graphene-Nanosheet

Coatings for Biomedical Applications”

Yi Liu, Jing Huang, and Hua Li

Hydroxyapatite (HA)/graphene nanosheet (GN) composite

coatings were deposited by vacuum cold spray (VCS). Signifi-

cant shape changes of HA nanograins during the coating deposi-

tion occurred. The nano-

structural features of HA

together with curvature al-

ternation of GN give rise to

dense structures. Based on

the microstructural charac-

terization, a structure model

was proposed to elucidate

the nanostructural charac-

teristics of the HA-GN

nanocomposites. Results

show that addition of GN

significantly enhances frac-

ture toughness and elastic

modulus of HA-based coatings, which is presumably accounted for

by crack bridging offered by GN in the composites. VCS HA-GN

coatings show potential for the repair or replacement of hard tissues.

“Nanocomposite Fe-Al Intermetallic

Coating Obtained by Gas Detonation

Spraying of Milled Self-Decomposing

Powder”

Cezary Senderowski

The nanocomposite structure of Fe-Al intermetallic coatings,

created in situ during gas detonation spraying (GDS) of as-milled

self-decomposing powder and containing disordered 8 nm FeAl

nanocrystals, was analyzed using scanning electron microscopy

(SEM) with energy-dispersive x-ray (EDX) spectroscopy, trans-

mission electron microscopy (TEM), selected-area electron dif-

fraction (SAED), and x-ray diffraction methods. The Fe-Al coating

is characterized by a sublayer morphology consisting of flattened

and partially melted splats containing a wide Al range from about

26 to 52 at.%, as well as Al

2

O

3

oxides, created in situ at the inter-

nal interfaces of splats

during the GDS process.

Complex oxide films,

identified as amorphous

Al

2

O

3

, which are formed

in the nanocrystalline Fe-

Al matrix of the GDS

coating, behave like a

composite reinforcement

in the intermetallic Fe-Al

coating. The combined

presence of nanosized

subgrains in the Fe-Al ma-

trix and the Al

2

O

3

nanoce-

ramic dispersoids significantly increases microhardness.

“Aircraft Skin Restoration

and Evaluation”

M. Yandouzi, S. Gaydos, D. Guo, R. Ghelichi,

and B. Jodoin

Cold spray technology

enables the deposition of

low porosity and oxide-free

coatings with good adhesion

and minimal changes in the

microstructure of coated

parts. The use of low-pres-

sure cold spray was used to

repair damaged Al-based

aircraft skin, hoping to ob-

tain dense coatings with

strong adhesion to the

Al2024-T3 alloy. In order to

prove the feasibility of using

cold spray as a repair

process for aircraft skin, se-

ries of characterization/tests

including microstructures,

microhardness, adhesion

strength, three-point bend-

ing, surface finish, fatigue

test, and corrosion resist-

ance were performed. Re-

sults reveal that cold spray

is suitable for the repair of

aircraft skin.

“Thermal Shock Resistance of Stabilized

Zirconia/Metal Coat on Polymer Matrix

Composites by Thermal Spraying Process”

Ling Zhu, Wenzhi Huang, Haifeng Cheng,

and Xueqiang Cao

Stabilized zirconia/metal coating systems were deposited on

the polymer matrix composites by a combined thermal spray

process. Effects of the thicknesses of metal layers and ceramic

layer on thermal shock resistance of the coating systems were in-

vestigated. According to the results of thermal shock lifetime, the

coating system consisting of 20 μm Zn and 125 μm 8YSZ exhib-

ited the best thermal shock resistance. Based on microstructure

evolution, failure modes and failure mechanism of the coating sys-

tems were proposed. The main failure modes were the formation

of vertical cracks and delamination in the outlayer of substrate,

Continued on page 12

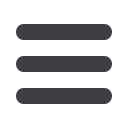

Schematic illustration demonstrates the

formation mechanisms of the HA-GN

nanocomposite coating.

TEM bright-field micrographs of

grains of as-sprayed coating with

nanocrystalline particles of

aluminum oxides.

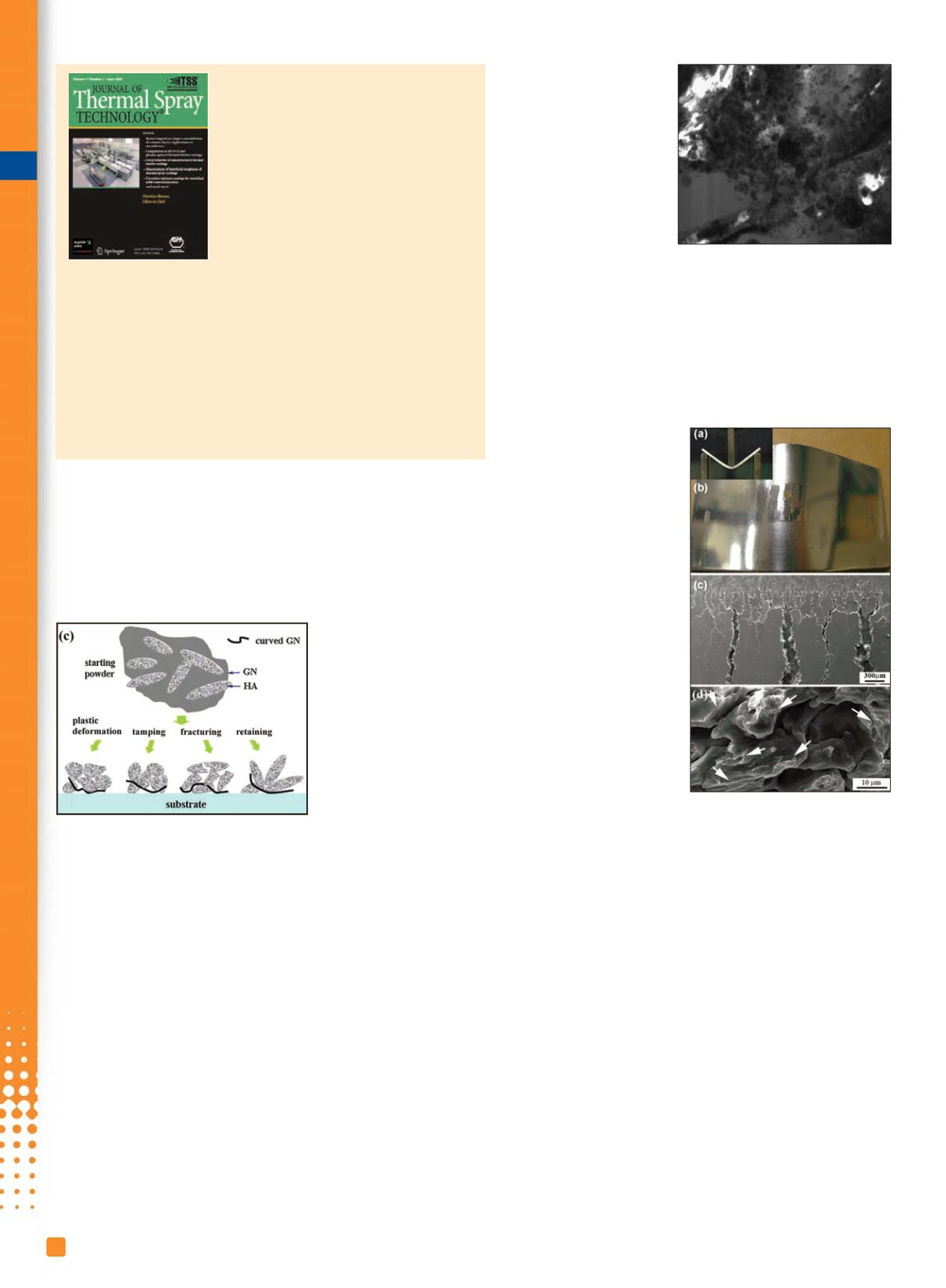

Repaired sample during the three-

point bending test and after 90°

bending, respectively (a, b). SEM

images at different magnifications

revealing the fracture nature that

took place during bending (c, d).