ADVANCED MATERIALS & PROCESSES •

NOVEMBER-DECEMBER 2014

58

i

T

S

S

e

8

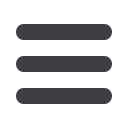

such as a UAV tail (Air Force Contract FA8650-09-C-1620).

The technology also embeds antenna patterns within com-

posite aerostructures, representing a unique class of systems

involving conformal load bearing antennas (CLAS). Other

advanced RF devices are also fabricated by the technology,

including rectifying antennas (for wireless power transmis-

sion) and frequency selective surfaces for reconfigurable

broadband antennas. Examples of printed conductor net-

works and antenna patterns are shown in Fig. 5.

Looking forward

Structural electronics is a rapidly growing business,

driven primarily by aerospace applications, but with signifi-

cant opportunities in many other industries including power

generation, automotive, oil and gas, and electronics. The abil-

ity to print heaters, temperature/heat flux sensors, and cir-

cuitry onto conformal structures without masking and

without post-heat treatment allows for new ruggedized de-

signs and improved product performance. Direct write tech-

nology provides a cost-effective method to produce smart

structures by integrating sensors and heaters within coatings.

The technology advances state-of-the-art design in compo-

nent instrumentation, diagnostic/distributed sensing, commu-

nication, and multifunctional structures.

iTSSe

For more information:

Jeff Brogan is the CEO of MesoScribe

Technologies Inc., 100 N. Country Rd., Setauket, NY 11733,

631.686.5710,

jbrogan@mesoscribe.com,

mesoscribe.com.

Fig. 5 —

Printed copper conductors and antenna patterns. Integrated wiring (left), UHF/VHF/GPS antenna on UAV (middle), structurally

integrated VHF antenna onto an aircraft wing to body fairing (right).