heat-treating furnace, process require-

ments and operating conditions often

change, sometimes dramatically, and gas

measurement must remain accurate.

For a variable-area rotameter, if it is nec-

essary to know the proper flow rate, be

aware that a change in temperature,

pressure, or specific gravity of the gas

from that for which the meter was cali-

brated will cause a serious error in the

indicated scale reading. It is quite com-

mon in a heat treat shop to find flowme-

ters operating at pressures and temper-

atures different from those for which

they were calibrated.

Mass flowmeters

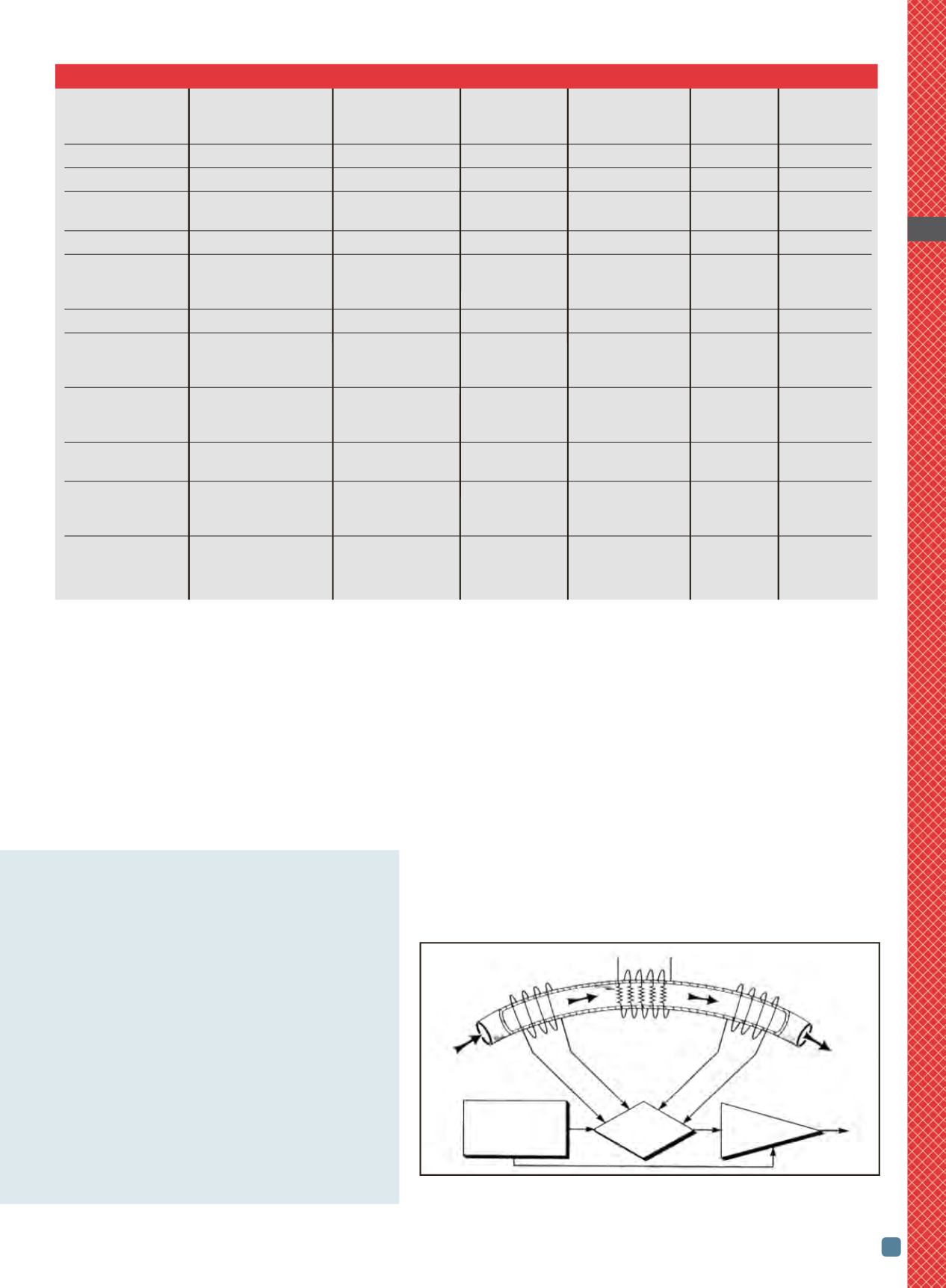

Thermal-mass flowmeters also are used

by heat treaters. In most industrial-grade

devices, gas enters the flow body and di-

vides into two flowpaths. Most of the flow

goes through the laminar-flow bypass,

creating a pressure drop that forces a

known fraction of the flow

through the sensor tube

(Fig. 1). A power supply is

used to direct a constant

amount of heat into the gas

stream. Resistance temperature-detector

(RTD) coils are placed around the bypass

sensor tube at its upstream and down-

stream ends. Heat is transferred to the

molecules of the flowing gas, independent

of pressure and temperature fluctuations.

The gas flow carries heat from the up-

stream coil to the downstream coil.

Therefore, the downstream coil has a

higher temperature and more resistance

than the upstream coil. The coils are legs

of a bridge circuit with the resultant out-

put voltage proportional to the differ-

ence between the coils’ resistance,

which, in turn, is proportional to the

mass flow rate. The two other parame-

57

ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

HTPRO

11

TABLE 1 — COMMONLY USED FLOW MEASUREMENT INSTRUMENTS BY FEATURE

Mechanical flow

Typical full-scale

Gas flow meter

Special installation reading level/

Electronic

accuracy, %

Typical

Pressure

type

requirements

scale type

flow reading of reading turndown

drop

Metal tube

Vertical mounting

Easy/linear

Available

3.5

3:1

Low

Metal cylinder tube Vertical mounting

Easy/linear

Available

1–2

25:1

Low

Glass or plastic

Vertical mounting

Easy/linear

No

1–2

10:1

Low

tube

Vane

None

Easy/linear

No

2–5

5:1

High/average

Moving orifice

Straight pipe

Complex/

Available

2–3

3:1–10:1 Low/average

upstream and

square root

downstream

Piston (with spring)

None

Easy/linear

No

1–5

5:1

Low/average

Orifice

Straight pipe

Hard/square root

Available

0.5–2

3:1–10:1

High

upstream and

downstream

Venturi

Straight pipe

Hard/square root

Available

0.5–2

3:1–10:1

Average

upstream and

downstream

Rotary impeller

None

Moderate/linear,

Available

0.5–2

10:1–20:1 Average

(Roots type)

total flow counter

Turbine

Straight pipe

Moderate/linear

Yes

0.5–3

10:1–20:1 Average

upstream and

downstream

Thermal mass

Straight pipe

Not applicable

Yes

1–2

10:1–100:1 Average/high

upstream and

downstream

as many of the gases involved are asphyxiants, as well

as being flammable, toxic, and possibly life threaten-

ing.

Also, electromagnetic flowmeters and all flow meas-

urement devices that use secondary instruments

such as pressure sensors to actuate a control valve or

send a signal to a remote source must be periodically

inspected, calibrated, repaired, and/or replaced. Im-

proper location of the flowmeter itself, the second-

ary sensor, or readout devices can result in

measurement errors and hidden costs.

Is it really necessary to learn about flowmeters

to be in control, stay in control, operate safely,

and keep operating costs as low as possible?

Simply stated, YES.

Fig. 1 —

Sensor tube measurement component of a thermal-mass flowmeter.

Courtesy of Omega Engineering Inc.

Power supply heater

T

1

, upstream

T

2

, downstream

temperature sensor temperature sensor

Bypass sensor tube

Flow

Linear

Bridge for output

Power supply

D

T

detection Amplifier