ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

55

HTPRO

9

protected most effectively. Finally, optimized steelmaking prac-

tices, including hot working, are critical for successful commer-

cialization of these alloys, and this optimization can be

challenging with the small heat sizes typically used for new steel

compositions targeted toward emerging markets.

Nevertheless, progress is being made. The German company

Buderus Edelstahl GmbH is active in this area and has reportedly

supplied custom heats of microalloyed case-hardening steels to

some customers. Recent work at Buderus is described by Hip-

pensteil

[5]

. Other industrial activities related to commercializa-

tion are summarized by Mohrbacher

[6]

. The potential benefits of

microalloy additions for pinning austenite grain boundaries could

also extend beyond carburizing alloys. Jansto notes that rolled

medium- and high-carbon steels can also benefit from such ad-

ditions

[3]

. In this case, the microalloy additions minimize grain

coarsening and grain size variations caused by temperature fluc-

tuations and inhomogeneities during reheating and hot rolling.

This, in turn, can facilitate development of new, ultrafine grain

steels with improved toughness, strength, and uniformity com-

pared with current products.

HTPRO

References

1. K. Loeser,Meeting theChallenges of LPC, VacuumCarburizing Sym-

posium, Dearborn, Mich., Sept., 2008.

2. M. McKimpson, Novel Steels for High Temperature Carburizing,

Final Technical Report, U.S. Department of Energy Award DE-

EE0003474, 2012,

osti.gov/scitech/biblio/1046914.3. S. Jansto, MicroNiobiumAlloy Approach inMedium and High Car-

bon Steel Bar, Plate and Sheet Products,

Met Trans B

, Vol 45B, April

2014, p 438–444.

4. C. Enloe, The Effect of Molybdenum on Niobium, Titanium Car-

bonitride Precipitate Evolution andGrainRefinement inHigh-Temper-

ature VacuumCarburizingAlloys, Ph.D. Dissertation, Colorado School

of Mines, 2013.

5. F. Hippenstiel, ImprovementWorking andUtility Properties of Clas-

sical and NewMo Alloyed Carburizing Steels, 3rd Intl. Conf. on Steels

for Cars and Trucks (SCT2011), June 2011, Salzburg, Austria.

6. H. Mohrbacher, Optimization of Molybdenum Alloyed Carburiz-

ing Steels by Nb Microalloying for Large Gear Applications, Asia

Steel 2012 Conf., Sept. 2012, Beijing,

niobelcon.com/NiobelCon/ Publications.htmlAcknowledgment:

A portion of the work described in this article

was supported by the U.S. Department of Energy under Award No.

DE-EE0003474.

For more information:

Marv McKimpson, Caterpillar Inc., (41)

Tech Ctr-E/Div. 854, 14009 Old Galena Rd., Mossville, IL 61552,

mckimpson_marv@cat.com,

cat.com.

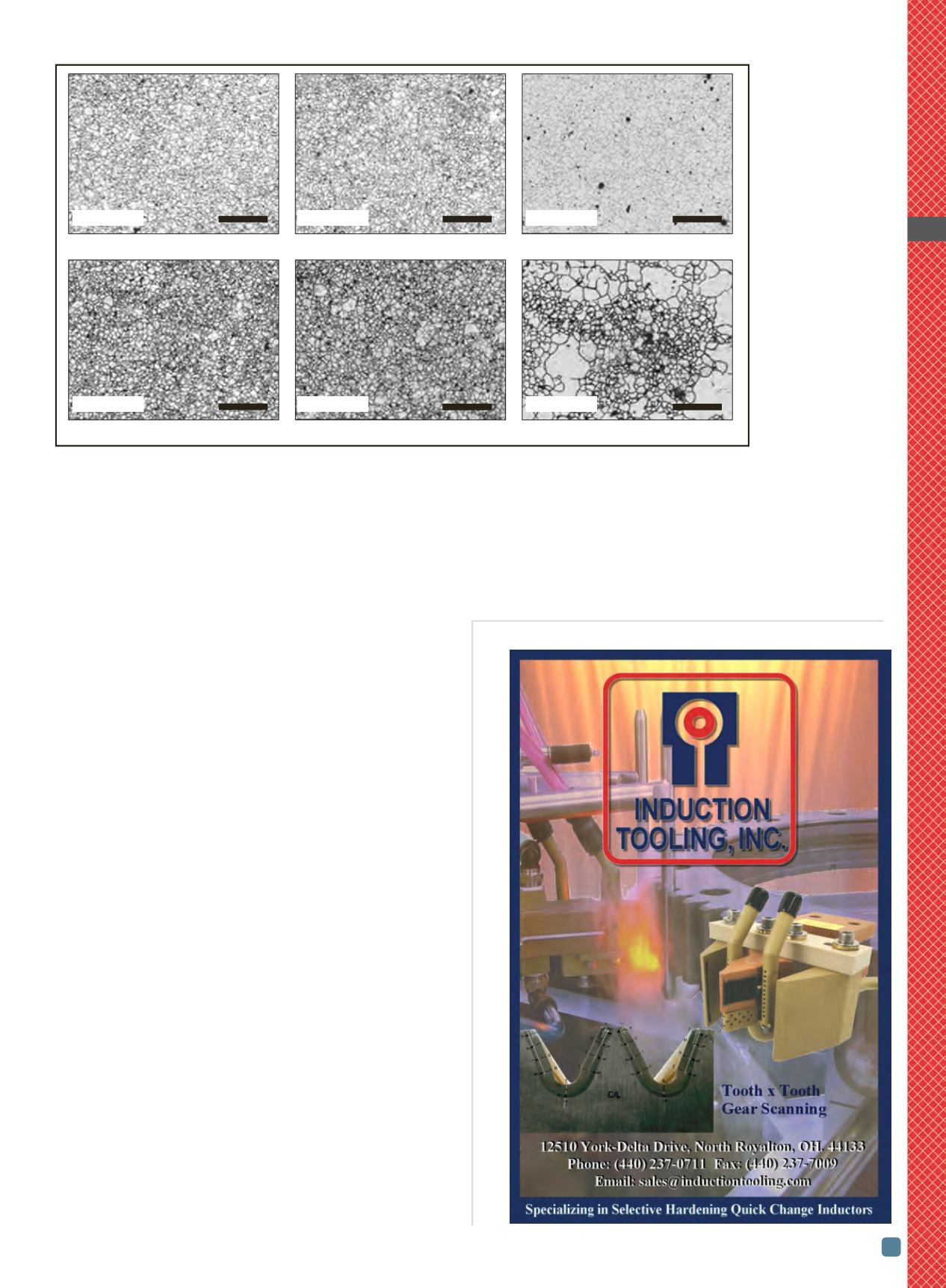

Fig. 4 —

Grain size

observed in a

microalloyed

carburizing steel as

a function of

thermal exposure

conditions. Note:

The first number in

the ASTM grain

size nomenclature

indicates the

smallest grain size,

the second number

the largest grain

size. Source: Ref 2.

200 mm

200 mm

200 mm

200 mm

200 mm

200 mm

900°C, 1 h

ASTM grain size 8–7

1000°C, 8 h

ASTM grain size 9–8

900°C, 8 h

ASTM grain size 9–8

1050°C, 8 h

ASTM grain size 8–6

950°C, 8 h

ASTM grain size 8–7

1100°C, 8 h

ASTM grain size 7–1