Because alloy steel hardenability is such an

important factor in part manufacturing, the

Center for Heat Treating Excellence (CHTE)

is conducting research aimed at learning

more about the performance of gas quenching

systems used to harden newer alloy steels. The

primary goal of the study is to establish a stan-

dard method to evaluate gas-quench steel

hardenability. Heat transfer coefficients will be

determined for different gas pressures and dur-

ing the cooling phase.

“The world is improving its alloys,” notes

Richard D. Sisson, George F. Fuller professor of

Mechanical Engineering at WPI and director of

CHTE. “New alloys are being developed to be

much harder and to be processed by gas

quenching, and we need to understand how

these alloys perform. We also need to be able

to characterize how fast new furnace designs

can cool the part.”

Another objective of the re-

search project is to evaluate

the cooling performance of

high-pressure gas-quench sys-

tems. Researchers will explore

what equipment is needed

and what conditions are re-

quired to ensure the desired

hardenability standard.

CHTE member Lynn Ferguson

of DANTE Solutions explains,

“Newer furnaces with higher

cooling capability can quench

using gas pressures of 10 to

20 bar. High-pressure gas

quenching (HPGQ) is gaining market share in the United States,

but because gas quenching is a slower process than oil quench-

ing, hardenability becomes more critical.”

Though it is a slower process, HPGQ is dis-

placing oil quenching, especially in Europe,

because it avoids part discoloration, quenching

vapors, potential for fires, and other cleanliness

and environmental issues associated with the

use of oil.

The project is being conducted through simula-

tion and lab testing, with much of the work

being carried out simultaneously. Researchers

are working with commercial software compa-

nies like DANTE Solutions, Dassault Systèmes

Simulia Corp. (ABAQUS) and Sente Software Ltd.

(JMatPro), whose software can simulate the re-

sponse of heat-treated parts. Specifically, sim-

ulations help researchers understand the

relationship between steel hardenability and

cooling performance in gas-quench systems.

The simulations also help

predict the actual behavior of

the parts given the amount

of gas used.

Currently, lab testing is being

conducted at WPI and will

eventually be conducted in

manufacturing

facilities.

Notes Kevin Rong, Higgins

Professor of Mechanical Engi-

neering and director of the

Computer-Aided Manufactur-

ing Laboratory at WPI, and

principal investigator for the

project, “In our testing to

date, we compared liquid

quenches with gas quenches

to identify how the microstructures of the material behave and

determine the differences. The findings have been interesting.”

ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

52

Developing Gas Quench Steel Hardenability Standards

HTPRO

6

About CHTE

The CHTE collaborative is an alliance between the industrial sector and university researchers to address short-term and long-term

needs of the heat-treating industry. Membership in CHTE is unique because members have a voice in selecting quality research proj-

ects that help them solve today’s business challenges.

Member research process

Research projects are member driven. Each research project has a focus group comprising members who provide an industrial per-

spective. Members submit and vote on proposed ideas, and three to four projects are funded yearly. Companies also have the op-

tion of funding a sole-sponsored project. In addition, members own royalty-free intellectual property rights to precompetitive

research, and are trained on all research technology and software updates.

CHTE also periodically undertakes large-scale projects funded by the federal government or foundations. These endeavors keep mem-

bers informed about leading edge technology.

CHTE current research portfolio

Other projects now in progress include:

Nondestructive Testing for Hardness and Case Depth, Induction Tempering, Gas Quench Steel Hardenability, Enhancements to CHTE

Software (CarbTool, CarboNitrideTool, and NitrideTool), and Cold Spray Nanomaterials (supported by ARL).

For more information about CHTE, its research projects, and member services, visit

wpi.edu/+chte, call 508.831.5592, or email Rick

Sisson at

sisson@wpi.edu, or Diran Apelian at

dapelian@wpi.edu.

CHTE member

Lynn Ferguson,

FASM, president

of DANTE

Solutions.

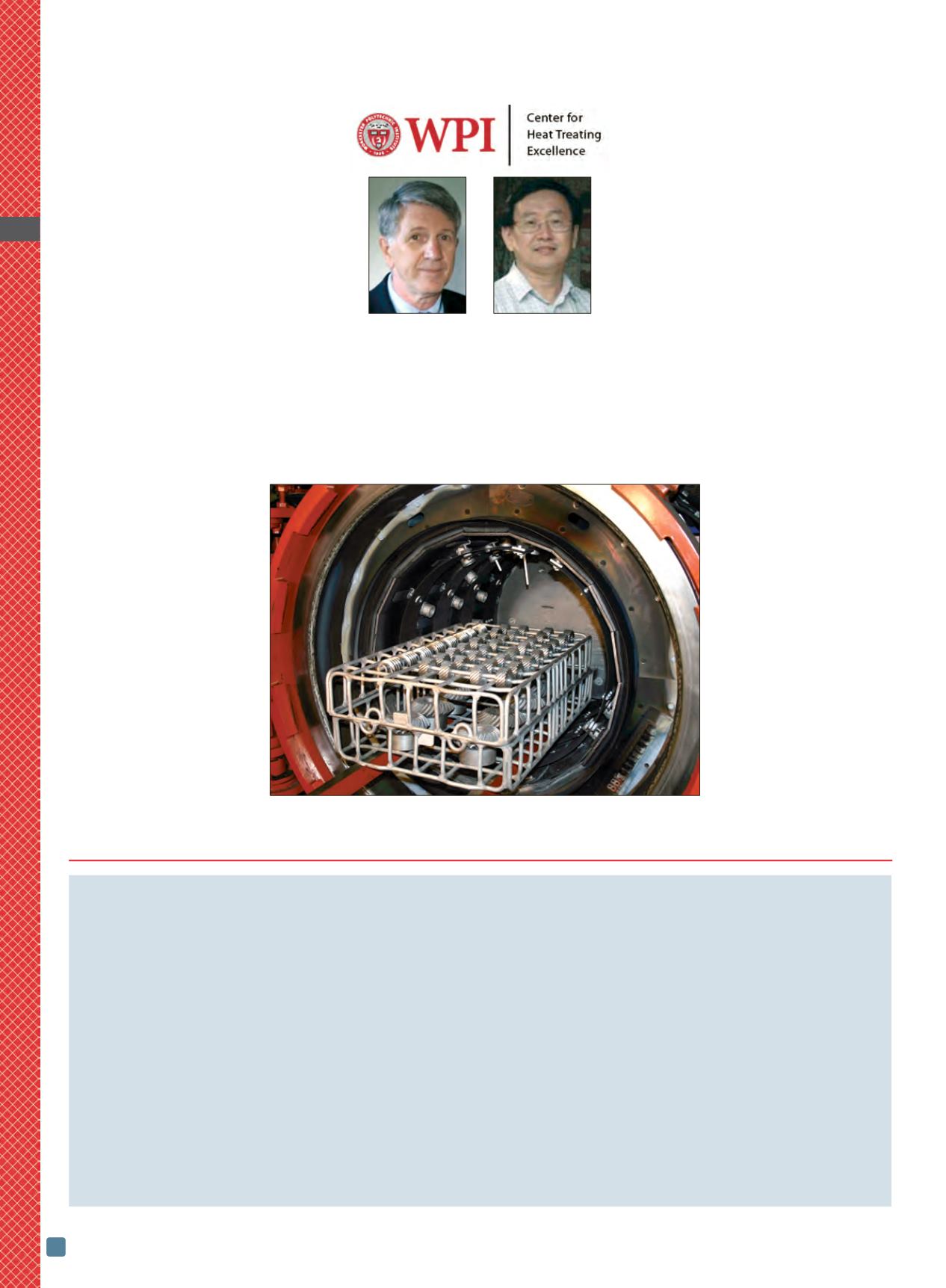

High-pressure

gas-quenching

nozzles in

vacuum furnace

chamber.

Professor Yiming

(Kevin) Rong,

Higgins

Professor of

Mechanical

Engineering and

director of the

Computer-Aided

Manufacturing

Laboratory at

WPI.