A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y / J U N E

2 0 1 7

9

Flexible glass membrane for medical

devices. Courtesy of Jaren Wilkey/BYU.

used in a range of applications includ-

ing medical devices, transformers, and

sports equipment.

www.ansto.gov.au.

FLEXIGLASS MINIATURIZES

MEDICAL TESTING

Researchers at Brigham Young

University, Provo, Utah, developed a

flexible glass membrane that could lead

to a new family of onsite, rapid analysis

medical devices. Glass has long been

a go-to material for medical testing

but its brittleness is a barrier in certain

applications. Currently, lab-on-a-chip

technology exists on the microscale,

but the new material, which bends

on the nanoscale and snaps back into

shape, could take testing to the next lev-

el of detail. “We’ve created glass mem-

branes that can move up and down and

bend,” explains electrical engineering

professor Aaron Hawkins. “They are

the first building blocks of a whole new

plumbing system that could move very

small volumes of liquid around.” The

glass membrane device would only re-

quire a drop or two of blood to run a

test, trapping and analyzing tiny biolog-

ical particles like proteins, viruses, and

DNA. Analysis time could be slashed:

Instead of shipping blood to a lab, the

new device could provide test results

on the spot.

byu.edu.

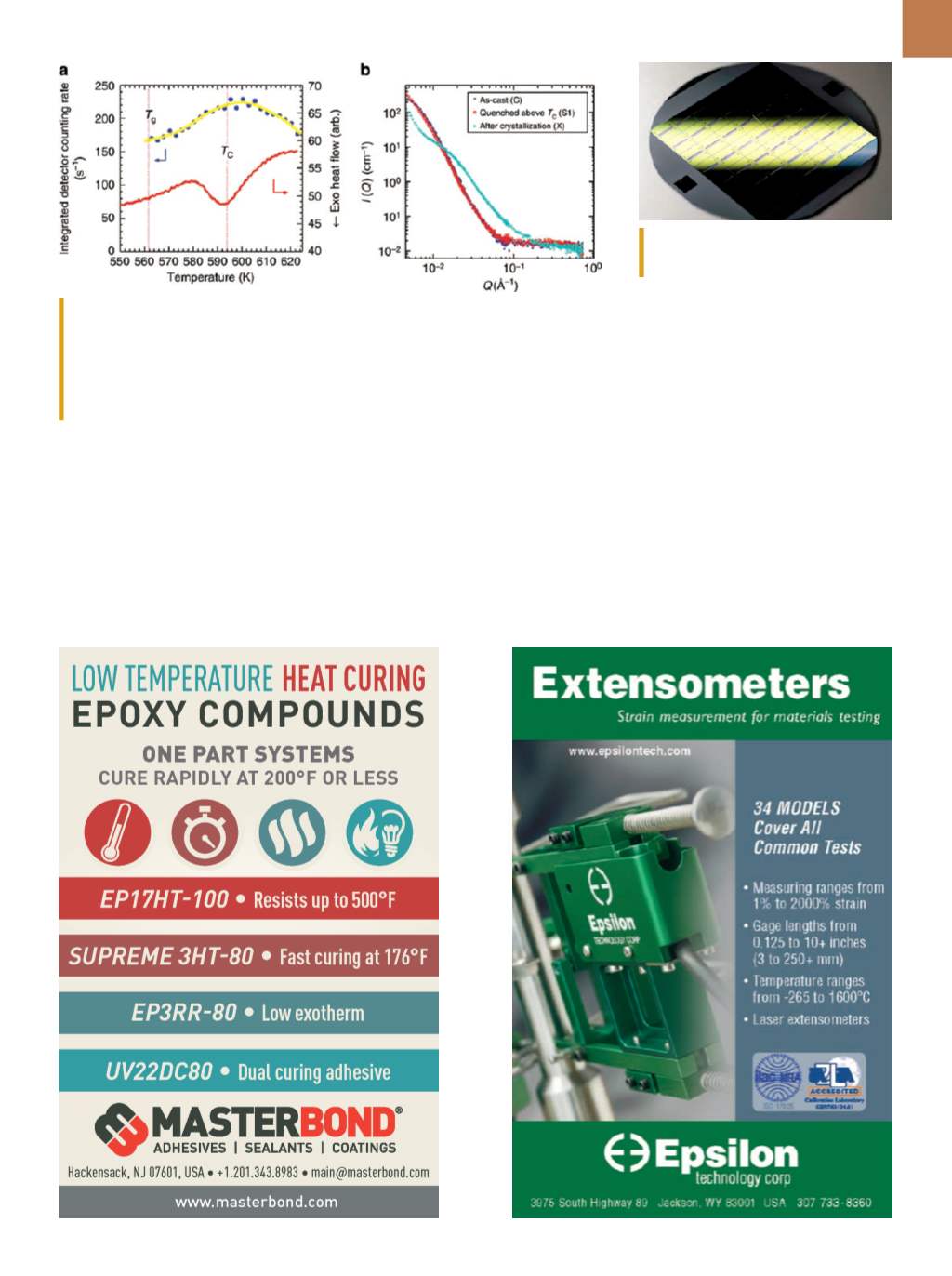

Results of simultaneous DSC-SANS measurements for the Pd41.25Ni41.25P17.5 alloy. (a) The

integrated detector counting rates as a function of temperature. The simultaneous DSC scan

is superimposed, showing a TC ~ 594 K at a heating rate of 2.5 K/min. The coexistence of two

phases can be clearly seen in the vicinity of Tc. (b) Full-Q range SANS data for three samples:

as-cast condition (C), quenched from 623 K a er the transformation had ended (S1), and

quenched a er crystallization at 673 K (X).