A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

8

METALS | POLYMERS | CERAMICS

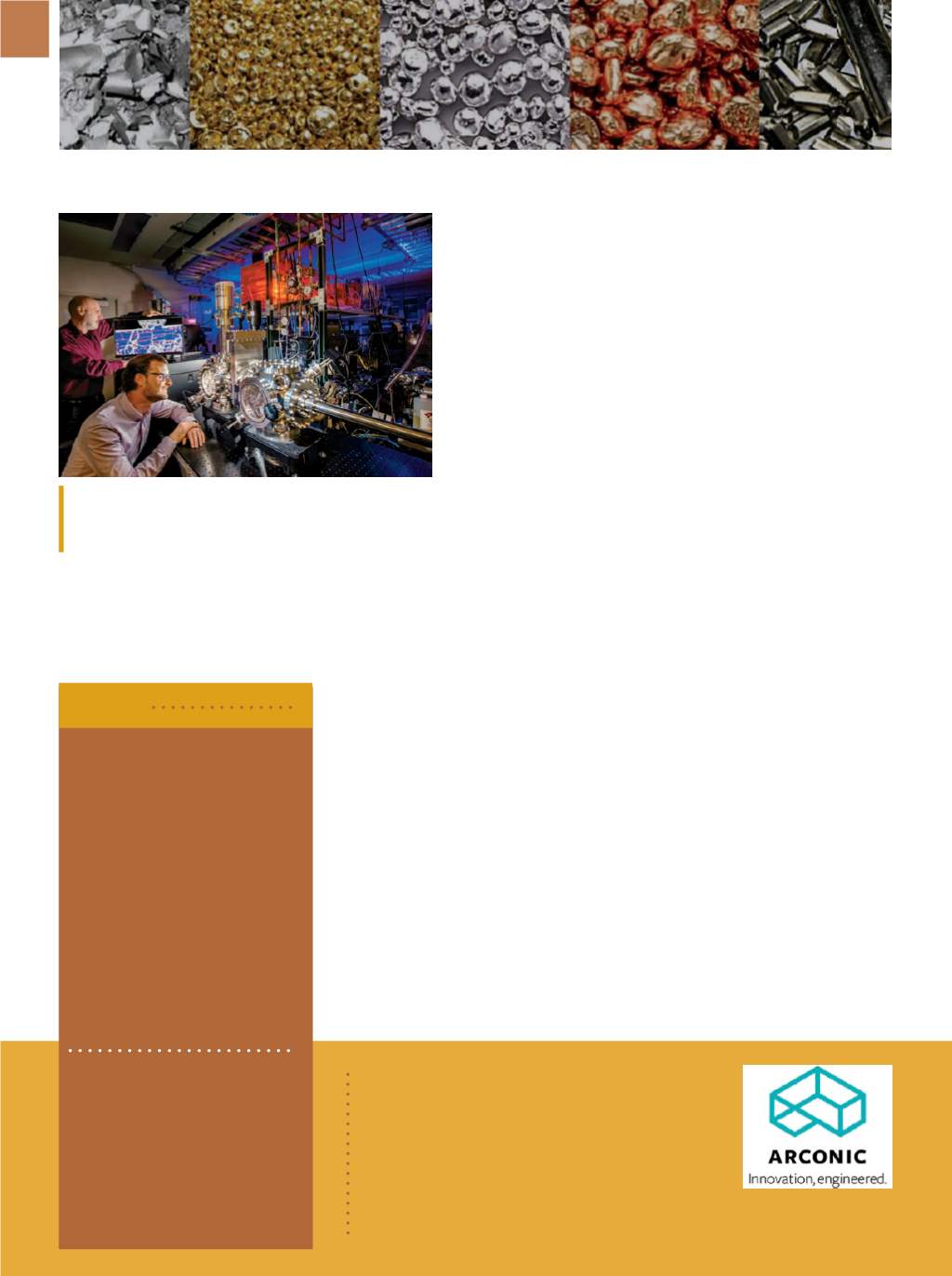

Michael Chandross, le , and Nicolas Argibay use computer

simulation and an ultrahigh vacuum tribometer for friction and

wear testing. Courtesy of Randy Montoya.

A new standard is forthcoming

from

ASTM International,

West

Conshohocken, Pa.—E3061, Test

Method for Analysis of Aluminum

and Aluminum Alloys by Induc-

tively Coupled Plasma Atomic

Emission Spectrometry (Perfor-

mance Based Method). Developed

by ASTM’s committee on analyt-

ical chemistry for metals, ores,

and related materials (E01), E3061

offers a performance-based meth-

od that also provides established

preparation and analysis tech-

niques.

astm.org.

Nucor Corp.,

Charlotte, N.C., will

invest $85 million to upgrade the

rolling mill at its steel bar mill in

Marion, Ohio.

Nucor Steel Marion

Inc.

is Ohio’s largest manufacturer

of rebar and signpost, capable

of producing over 400,000 tons

annually.

nucor.com.

In a multiyear agreement,

Toyota North America

named

Arconic,

New York, as the sole aluminum

sheet supplier for the Lexus RX, a luxury SUV that

debuted last year featuring aluminum exterior

panels. Arconic will supply the sheet from its plants

in Davenport, Iowa, and Danville, Ill., and estimates

that its automotive sheet revenue could grow to

$1.3 billion in 2018.

toyota.com, arconic.com.

BRIEFS

MAKING CONTACT WITH A

NEW PREDICTIVE MODEL

Scientists at Sandia National Lab-

oratories, Albuquerque, N.M., devel-

oped a new predictive model for metal

on metal friction be-

havior based on ma-

terials properties. Their

research demonstrates

thatmicrostructural sta-

bility

governs

fric-

tion behavior, giving

engineers a much more

precise approach to

material characteriza-

tion, selection, and de-

sign. “You go from just

having to say, ‘The

material’s behavior will

be this because wemea-

sured it in those con-

ditions’ to saying, ‘I can

tell you what conditions

you can run in and get the behavior

you want,’” explains materials scientist

Nicolas Argibay. Until now, engineers

applied rules of thumb for different

conditions along with the conventional

wisdom that harder materials create

less friction.

The new model could revolution-

ize design of electrical contacts, includ-

ing those used in electric cars and wind

turbines. Researchers are developing

a prototype for a copper-against-cop-

per alloy rotary electrical contact for

wind turbines, revisiting an approach

that was not workable before the new

predictive model was discovered. Ulti-

mately, the model may allow the elec-

trical contacts industry to turn to high-

er-performance direct current devices

instead of the alternating current devic-

es now in use.

sandia.gov.

IT’S JUST A PHASE

An international team of research-

ers discovered a hidden amorphous

phase in a class of metallic glass. Led

by researchers from City University of

Hong Kong, the team examined palla-

dium-nickel-phosphorus metallic glass

during heating. Reportedly for the first

time ever, the scientists simultaneously

assessed changes in structure—by mea-

suring small-angle neutron scattering

and heat absorption—using differential

scanning calorimetry.

“We were able to directly correlate

changes in the structure of the material

with the energy required for that struc-

ture to change,” explains Elliot Gilbert,

instrument scientist at the Australian

Center for Neutron Scattering, where

the experiment took place. Other labs

provided high-resolution microscopy

images, electron diffraction patterns,

and synchrotron x-ray measurements,

which showed a rearrangement of

atomic clusters with temperature.

Unlike most metals, which have

atoms packed into regular arrays, me-

tallic glass is composed of atoms in a

disordered arrangement that has long

interested scientists because it imparts

valuable properties, such as hardness,

corrosion resistance, and formability.

The discovery could allow re-

searchers to induce this amorphous

phase in metallic glass, tuning the

properties of the material to better

suit different purposes. Metallic glass is