CASE STUDY

iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y / M A R C H

2 0 1 7

4 7

15

iTSSe

TSS

mitigate corrosion of carbon steel in seawater, but there are

concerns regarding its suitability in CO

2

-containing solutions.

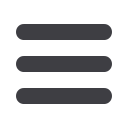

A 30-day test was carried out during which carbon steel speci-

mens arc-sprayedwith aluminumwere immersed in deionized

water at ambient temperature bubbled with 0.1 MPa CO

2

. The

acidity (pH) and potential were continuously monitored, and

the amount of dissolved Al

3

+ ions was measured after com-

pletion of the test. Some dissolution of TSA occurred in the

test solution leading to a nominal loss in coating thickness.

Potential measurements revealed that polarity reversal oc-

curs during the initial stages of exposure, which could lead to

preferential dissolution of carbon steel in the case of coating

damage. Thus, one needs to be careful while using TSA in CCS

environments (Fig. 5).

Fig. 5 —

Experimental setup showing the arrangement of reactors.

JTST

HIGHLIGHTS

Organized by:

THERMAL SPRAY CHARACTERIZATION:

MATERIALS, COATINGS AND PROCESSES

REGISTER TODAYA

2

0

1

7

A

A P R I L 1 1 - 1 2 , 2 0 1 7 • C h a r l e s t o n , S o u t h C a r o l i n a

CO-LOCATED WITH AEROMAT

THE TOP AEROSPACE MATERIALS

CONFERENCE IN THE INDUSTRY

W W W . A S M I N T E R N A T I O N A L . O R G / W E B / T S S - 2 0 1 7THE FUTURE OF THERMAL SPRAY CHARACTERIZATION!