iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y / M A R C H 2 0 1 7

4 2

10

iTSSe

TSS

Ni-20Cr coating on an AISI 4130 steel versus an aluminum sub-

strate. The softer aluminum substrate does not provide any

resistance to the particles that impinge on it at high velocity,

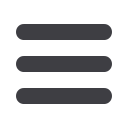

Fig. 7 —

SEMs of aluminum cold spray coating on magnesium

substrate: (a) without heat treatment, air cooled; (b) 250°C (480°F),

1 h holding time, air cooled; (c) 300°C (570°F), 1 h holding time, air

cooled.

as shown by the first layer of particles, which undergo little

or no deformation (Fig. 6 b), compared to the steel substrate

(Fig. 6 a). In each case, upon heat treatment, a thin diffusion

layer forms along the interface, as shown in the scanning elec-

tron micrograph in Fig. 6 (c). The nature of the interdiffusion

layer is established by EDS analysis of the chemistry, as shown

in Fig. 6 (d). Similarly, SEM is also used extensively to study the

intersplat coating characteristics in the as-sprayed versus heat

treated condition, as shown in Fig. 7 (a) to (c).

~iTSSe

For more information:

Dheepa Srinivasan is a principal en-

gineer at GE Power, GE India Technology Center, Bangalore,

dheepa.srinivasan@ge.com,

www.ge.com. This article series is

adapted from

Chapter 5, Cold Spray—Advanced Characteriza-

tion,

in High Pressure Cold Spray—Principles and Applications,

edited by Charles M. Kay and J. Karthikeyan (ASM, 2016).

FEATURE ARTICLE