iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y / M A R C H

2 0 1 7

4 5

iTSSe

TSS

13

The

Journal of Thermal Spray Technol-

ogy (JTST),

the official journal of the

ASM Thermal Spray Society, publishes

contributions on all aspects—funda-

mental and practical—of thermal spray

science, including processes, feedstock

manufacture, testing, and characteri-

zation. As the primary vehicle for ther-

mal spray information transfer, its mission is to synergize

the rapidly advancing thermal spray industry and related

industries by presenting research and development efforts

leading to advancements in implementable engineering

applications of the technology. Articles from the January is-

sue, as selected by

JTST

Editor-in-Chief Armelle Vardelle, are

highlighted here. This issue will feature papers based on pre-

sentations at ITSC 2016. In addition to the print publication,

JTST

is available online through springerlink.com. For more

information, visit asminternational.org/tss.

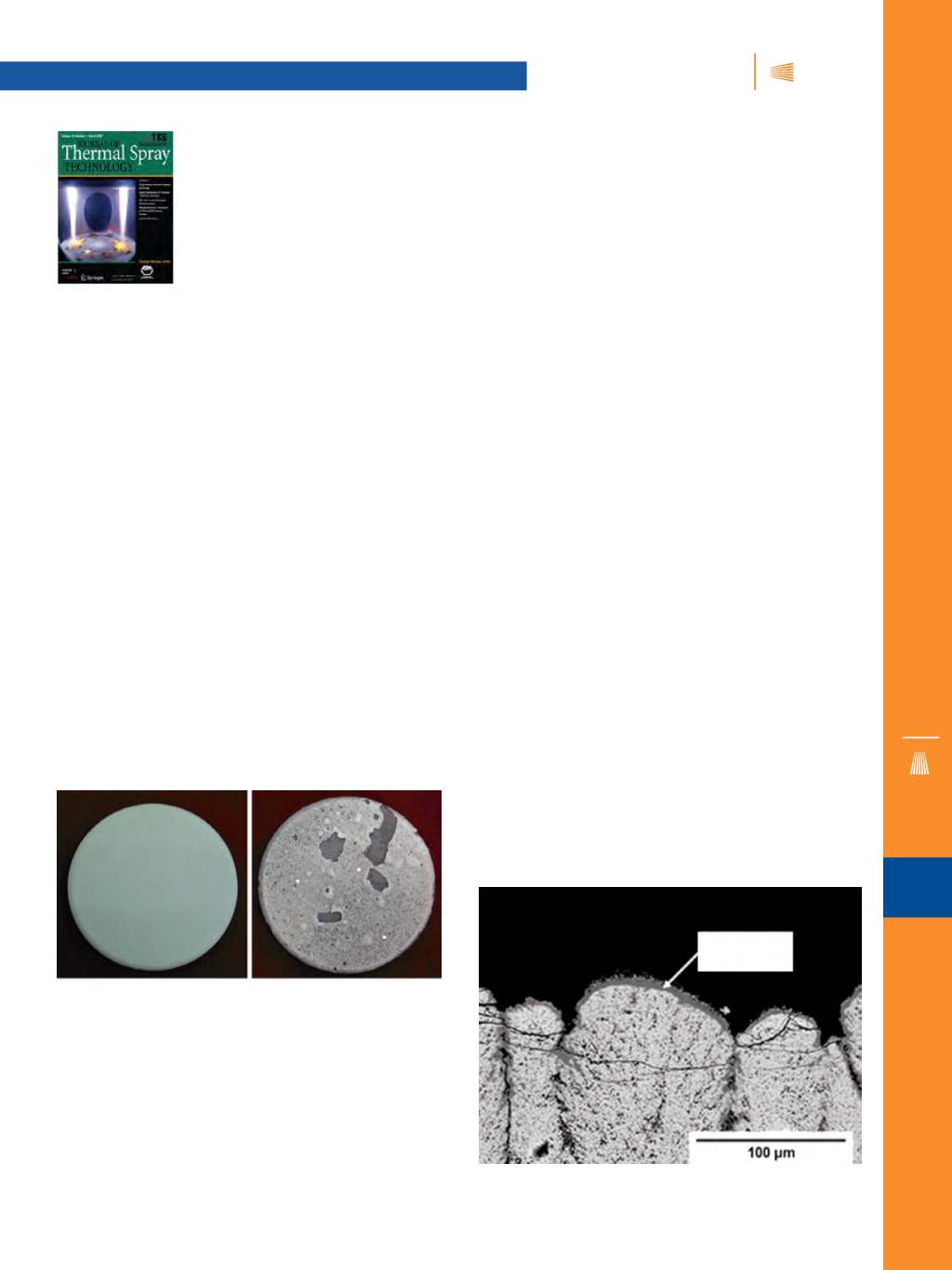

THERMAL CYCLING BEHAVIOR OF QUASI-

COLUMNAR YSZ COATINGS DEPOSITED BY

PS-PVD

Jiasheng Yang, Huayu Zhao, Xinghua Zhong, Fang Shao,

Chenguang Liu, Yin Zhuang, Jinxing Ni, and Shunyan Tao

Columnar-structured thermal barrier coatings, due

to their high strain tolerance, are expected to substantially

extend turbine lives and improve engine efficiencies. In this

paper, a plasma spray-physical vapor deposition (PS-PVD)

process was used to deposit yttria partially stabilized zirco-

nia (YSZ) coatings with quasi-columnar structures. Thermal

cyclic tests on burner rigs and thermal shock tests using a

coating surface during burner rig tests with the coating sur-

face temperature of ~1250°C. Failure of the coating is mainly

due to the break and pullout of center columnar segments

(Fig. 1).

HOT CORROSION MECHANISM IN MULTILAYER

SUSPENSION PLASMA SPRAYED GD2ZR2O7/

YSZ THERMAL BARRIER COATINGS IN THE

PRESENCE OF V

2

O

5

+ NA

2

SO

4

Krishna Praveen Jonnalagadda, Satyapal Mahade,

Nicholas Curry, Xin-Hai Li, Nicolaie Markocsan, Per Nylén,

Stefan Björklund, and Ru Lin Peng

This study investigates corrosion resistance of two-

layer Gd

2

Zr

2

O

7

/YSZ, three-layer dense Gd

2

Zr

2

O

7

/ Gd

2

Z

r2

O

7

/

YSZ, and a reference single-layer YSZ coating with a similar

overall top coat thickness of 300-320 µm. All coatings were

manufactured by suspension plasma spraying resulting in

a columnar structure except for the dense layer. Corrosion

tests were conducted at 900°C for 8 h using V

2

O

5

and Na

2

SO

4

as corrosive salts at a concentration of approximately 4 mg/

cm

2

. SEM investigations after the corrosion tests show that

Gd

2

Zr

2

O

7

-based coatings exhibited lower reactivity with the

corrosive salts and the formation of gadolinium vanadate

(GdVO

4

) accompanied by the phase transformation of zir-

conia was observed. It is believed that the GdVO

4

formation

between the columns reduced the strain tolerance of the

coating. Further, due to the fact that Gd

2

Zr

2

O

7

has a lower

fracture toughness value, this made it more susceptible to

corrosion-induced damage. In addition, presence of a rela-

tively dense layer of Gd

2

Zr

2

O

7

on the top did not help reduce

corrosion-induced damage. For the reference YSZ coating,

the observed corrosion-induced damage was lower, proba-

bly due to a combination of more limited salt penetration,

the SPS microstructure, and superior fracture toughness of

YSZ (Fig. 2).

Fig. 1 —

Photographs of YSZ TBCs (a) before and (b) after thermal

cycling for 623 cycles.

Fig. 2 —

Cross-section of two-layer gadolinium zirconate coatings

showing GdVO

4

on the top surface.

JTST

HIGHLIGHTS

GdVO

4

(a)

(b)

B

heating and water-quenching method were applied to eval-

uate the thermal cycling and thermal shock behaviors of

structured thermal barrier coatings (TBCs). Evolution of the

microstructures, phase composition, residual stresses, and

failure behaviors of quasi-columnar YSZ coatings before and

after thermal tests was investigated. The quasi-columnar

coating obtained had an average life of around 623 cycles

when the spallation area reached about 10% of the total

C

A