A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U L Y / A U G U S T

2 0 1 6

9

The Cadillac CT6 features a body made of

62% aluminum.

from Ichikoh Japan and INEOS Styrolu-

tion, Singapore. Ichikoh was searching

for a processing solution that looks

good at the weld joints of plastic parts.

As conventional weldingmethods were

unable to meet the innovative design

parameters, a new laser welding tech-

nique was used for the rear lamp hous-

ing, which offers more design freedom

and better surface appearance. The

new laser welding technique also has

the potential to generate more stabil-

ity and higher mechanical strength at

welded areas compared to conven-

tional methods.

In addition to the new technique,

the right material was needed. The

challenge with most black or dark

colored polymers is their high sensi-

tivity to laser beams, which results in

uneven surfaces at the weld joint when

a laser is applied. INEOS Styrolution

custom developed Novodur HH-112,

a high-heat acrylonitrile butadiene

styrene (ABS) specialty styrenic grade

that meets Ichikoh’s performance and

aesthetic requirements. This is the

first time an ABS resin has been used

for a black laser welded application.

ineos-styrolution.com.

CADILLAC CT6 SHAVES

WEIGHT WITH ALUMINUM

The 2016 Cadillac CT6 sports a

body made of 62%aluminum fromNov-

elis, Atlanta. By using aluminum and

advanced joining techniques, Cadillac

achieved significant weight savings,

making the full-size luxury sedan com-

parable in weight to the midsize CTS

sedan. When compared to a similar

size vehicle using predominantly high-

strength steel, the CT6 is approximately

220 lb lighter.

In both North America and Asia,

Novelis aluminum is used throughout

the vehicle body, including the pas-

senger and rear compartments, roof

structure, outer body panels, and door

and deck lid structures. The CT6 fea-

tures one of the most advanced mixed

use automotive body structures in

the industry, including all-aluminum

exterior body panels and rear-drive

architecture. GM’s advanced joining

methods are used to fabricate the

vehicle structure, including a propri-

etary aluminum spot welding technol-

ogy that reduces weight and increases

strength and efficiency. Laser weld-

ing, flow drill fasteners, and self-

piercing rivets are also used, along

with nearly 600 ft of advanced struc-

tural adhesives. The CT6 also features

a 10%stiffer body than its competitors.

novelis.com, gm.com.

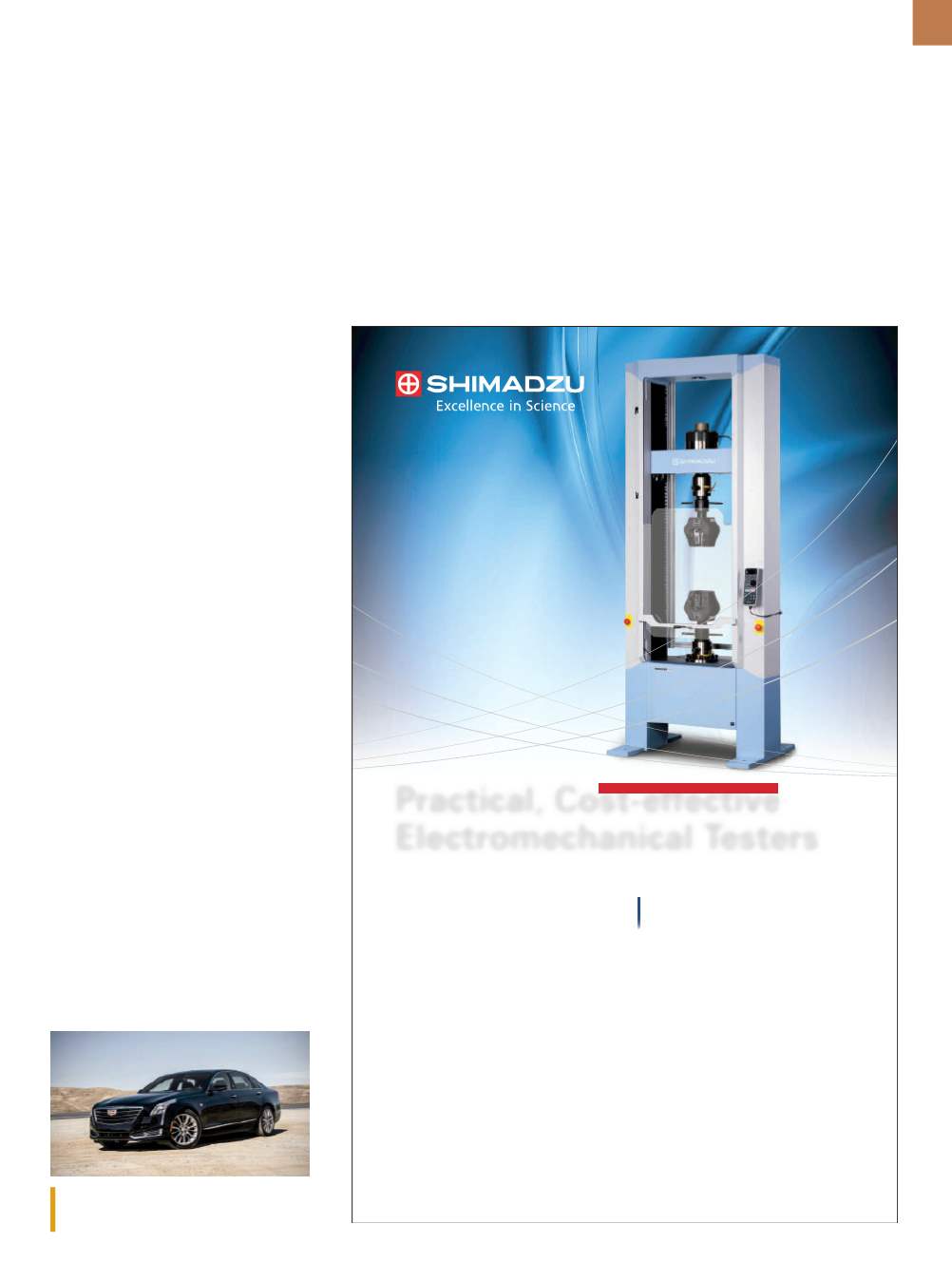

Combining advanced specifications with an affordable, modern design, Shimadzu’s AGS-X Series of floor and tabletop universal testers delivers practical solutions across a wide range of applications. By incorporating multiple control options, load cells with maximum capacities from 1 N to 300 kN, and the utmost in safety considerations, the AGS-X series is the choice for easier, more efficient testing . Shimadzu’s AGS-X Series features: ■ Accurate stress-strain curves with Class 0.5 load cells ■ High-speed data sampling up to 1 msec (1 kHz) ■ Precise stress- and strain-controlled testing ■ Comprehensive safety measures ■ Easy-to-use software with a refined user interface for more efficient, effective testingShimadzu Scientific Instruments Inc., 7102 Riverwood Dr., Columbia, MD 21046, USA

Learn more. Call (800) 477-1227 or visit us online at www.ssi.shimadzu.com/AGSX Practical, Cost-effective Electromechanical Testers In addition, a comprehensive selection of grips, compression plates, jigs, extensometers, and other accessories allow configurations to be tailored to almost any application. Adaptable to Countless Applications