A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 6

3 0

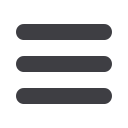

are held in position by a bursting disc

(Fig. 7).

In the first chamber, hydrogen

gas is compressed to 40 bar, while

the second chamber is evacuated to

0.1 Mbar. The target is mounted at the

end of the second chamber. Once the

pressure difference between the two

chambers is maximized, a shock wave

is sent into the compressed chamber

via a piston using a standard 12 bore

shotgun cartridge. This exceeds the

pressure specification of the bursting

disc and contents are fired through two

laser timing points into the target. In

this study, muzzle velocities reached

11,000 mph and a range of metal foils

were used as targets.

IMPACT RESULTS

Three different metal foils targets

were used, each featuring a 203

μ

m

thickness:

(a) Half hard 302 austenitic stainless

steel

(b)Annealed beryllium-copper alloy 25

(c) 2024T3 aluminum alloy

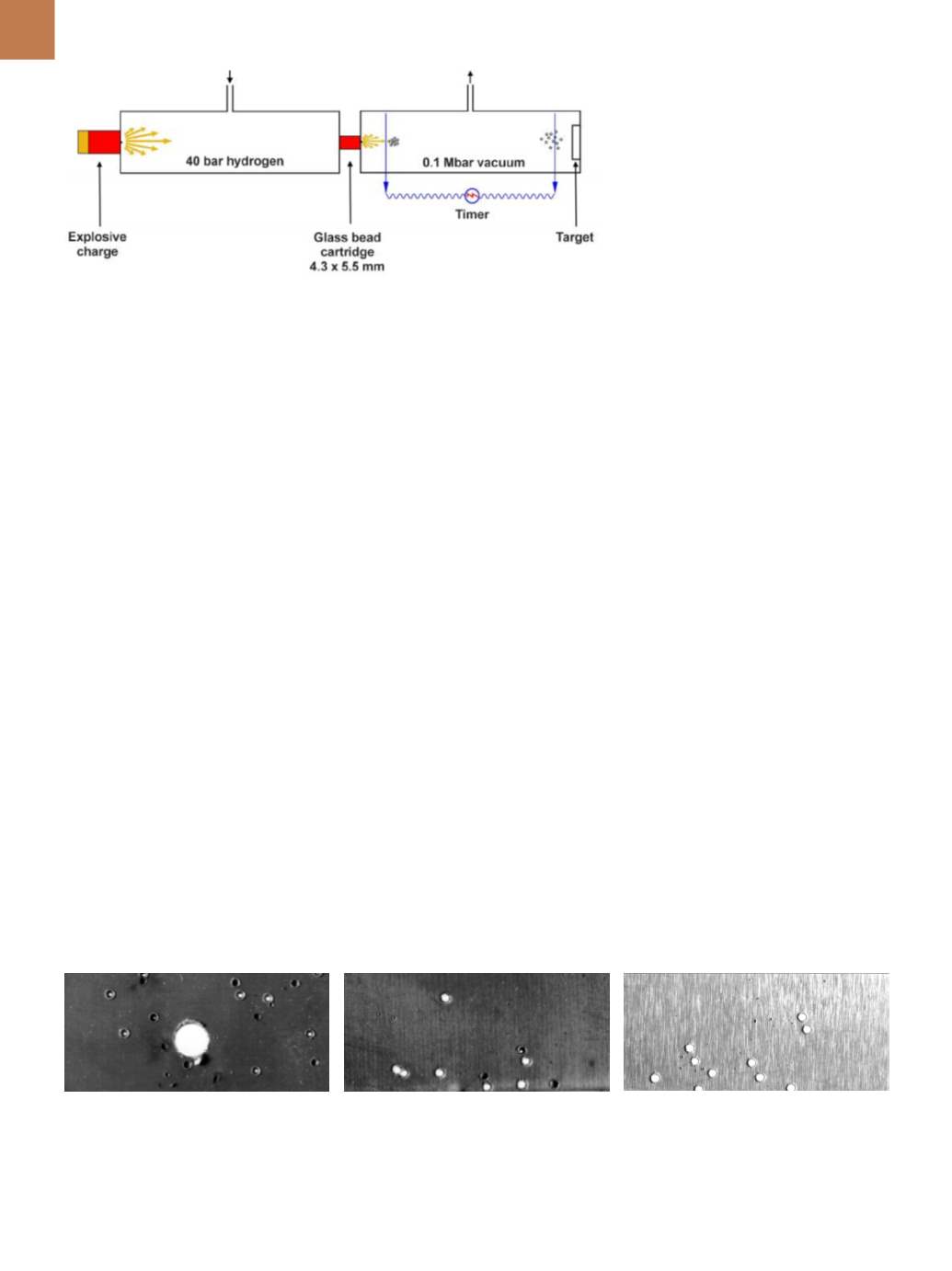

Figure 8 shows impact results for

the three materials using 177-

μ

m glass

microspheres travelling at 11,000 mph.

The dark microcraters show incom-

plete penetration, while those with

white centers show that the beads

have partially penetrated the metal.

The large hole in the stainless steel foil

was caused by a 1-mm ball bearing.

Note that the hole is perfectly round

because the speed was so high that the

metal did not have time to distort.

With regard to the stainless steel (a),

some

blind

microcraters are evident

where microspheres failed to pene-

trate, while other microcraters punc-

tured the foil. This could be due to

very small differences in the particle

size of the microspheres or an inho-

mogeneous structure in the stainless

steel. The annealed beryllium-copper

(b) showed similar results. In the case

of the aluminum alloy (c), however, all

the microspheres passed, showing less

resilience in the material to cosmic dust

impact.

CONCLUSION

By using glass microspheres to

model cosmic dust, it is possible to

simulate conditions found in space.

This enables aerospace engineers to be

more precise in specifying which mate-

rials should be used on the outside of

space vehicles, such as the Interna-

tional Space Station, in order to pro-

vide a safe work environment for the

astronauts.

Similarly, astronauts’ protective

suits, helmets, and visors were opti-

mized for safety by using the glass

microspheres and hypervelocity light

gas gun. The enhanced space apparel

now offers greater protection for astro-

nauts—even when they venture outside

the spacecraft to repair damage caused

by cosmic dust.

~AM&P

For more information:

Graham Ride-

al is CEO, Whitehouse Scientific Ltd.,

Whitchurch Rd., Waverton, Chester,

CH3 7PB, UK,

info@whitehousescientif- ic.com+44.0.1244.332626,

whitehouse- scientific.com.

Acknowledgment

The author thanks the team from

the University of Kent: Michael Baron,

who initiated the work; Mike Cole, who

operated the gun; and Mark Burchell for

inspiration.

Bibliography

1. M. Burchell, et al., Hypervelocity

Impact Studies Using the 2MV Van De

Graaff Accelerator and Two-Stage Light

Gas Gun of the University of Kent at

Canterbury,

Mea. Sci. Technol.,

V 10,

p 41-50, 1999.

2.

www.whitehousescientific.com.

3.

www.nist.gov.4. Image Analysis—Developing a

Robust Validation Procedure, pre-

sented by Graham Rideal at PARTEC,

Nuremberg, April 2016.

Fig. 7 —

Simplified schematic of hypervelocity gas gun.

Fig. 8 —

Impact results for 177-

μ

mglass microspheres travelling at 11,000mph. Half hard 302 austenitic stainless steel (a), annealed beryllium-

copper alloy 25 (b); 2024T3 aluminum alloy (c). Courtesy of M. Baron, University of Kent.

(a)

(b)

(c)