A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y

2 0 1 6

2 7

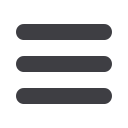

Fig. 6 —

Robotic cold spraying (a) and

post-machining (b) operations.

Fig. 7 —

Repaired and finished components:

(a) Pilot OD, (b) stator bore ID, (c) housing

mating surface, and (d) housing bore.

Courtesy of L.J. Walch.

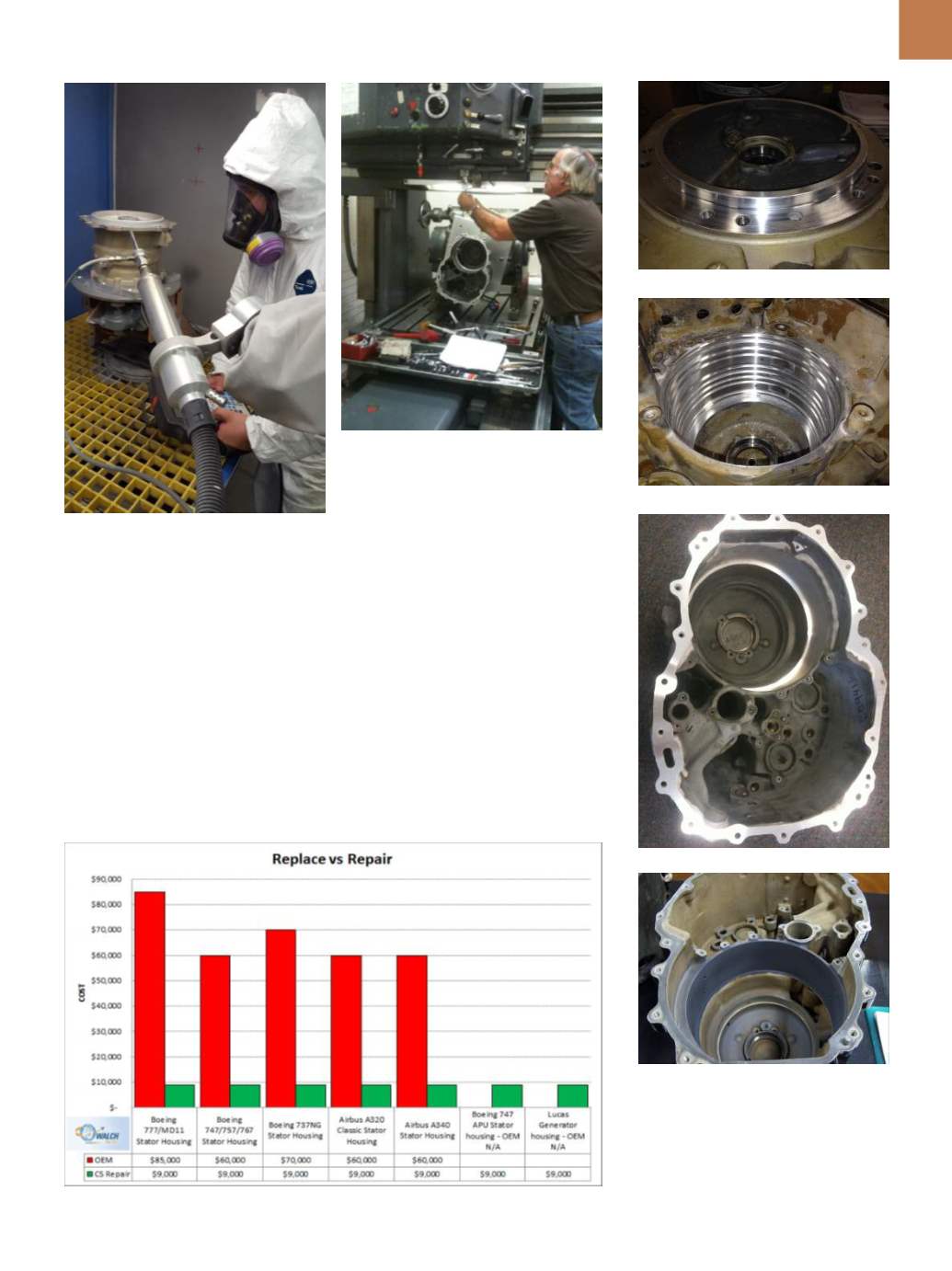

Fig. 8 —

Relative cost of cold spray repair versus replacement for IDGs. Courtesy of L.J. Walch.

in commercial aircraft. The process

enables the aerospace industry to

recover high-value and irreplaceable

components that otherwise would be

scrapped—at a fraction of their replace-

ment cost—thus maximizing profitabil-

ity.

~AM&P

For more information:

Julio Villa-

fuerte is a corporate technology strat-

egist at CenterLine (Windsor) Ltd.,

415 Morton Dr., Windsor, Ontario N9J

3T8, 519.734.8464,

julio.villafuerte@ cntrline.com,

www.cntrline.com.

Acknowledgments

The authors acknowledge valu-

able contributions made by CenterLine

(Windsor) Ltd. and L.J. Walch.

References

1. A.P. Alkhimov, et al., Gas-Dynamic

Spraying Method for Applying a

Coating, U.S. Patent 5,302,414,

April 12, 1994.

2. A.I. Kashirin, O.F. Klyuev, and T.V.

Buzdygar, Apparatus For Gas-Dynamic

Coating, U.S. Patent 6,402,050, June

11, 2002.

(a)

(b)

(a)

(b)

(c)

(d)