A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y

2 0 1 6

2 9

using tweezers—a time-consuming

procedure that made exact size match-

ing difficult. This, in turn, resulted in

questionable reproducibility. Use of

monodisperse (single size) glass beads

enabled a much larger number of beads

to be used at a size distribution signifi-

cantly narrower than could ever be pro-

duced manually. Further, the extensive

size range made it possible to replicate

almost any cosmic dust particle.

These

monodisperse

micro-

spheres are prepared using a number

of different methods including sieving

and sedimentation. However, because

glass microspheres are manufactured

from an industrial melt process, the

possibility exists for some irregular

particles (cullet) not to be spherulized

in the heating column. Therefore, they

must be removed from the bulk of the

product.

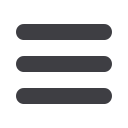

The principle analytical tool, the

ShapeSizer Optical Image Analyzer

(Fig. 5), is essentially a computer con-

trolled, high power microscope with

magnifications up to 80 nm pixel, which

was specifically designed to measure

and quantify particle size and shape.

All measurements are traceable

to the National Institute of Standards

and Technology (NIST), Gaithersburg,

Md., and have a unique validation pro-

cedure that guarantees repeatability.

It is therefore possible to monitor the

progress of the classification and shape

sorting in the manufacturing process.

The microspheres used in this experi-

ment were 177

±

3.7

μ

m, with 90% of the

distribution falling between 171 and

184

μ

m.

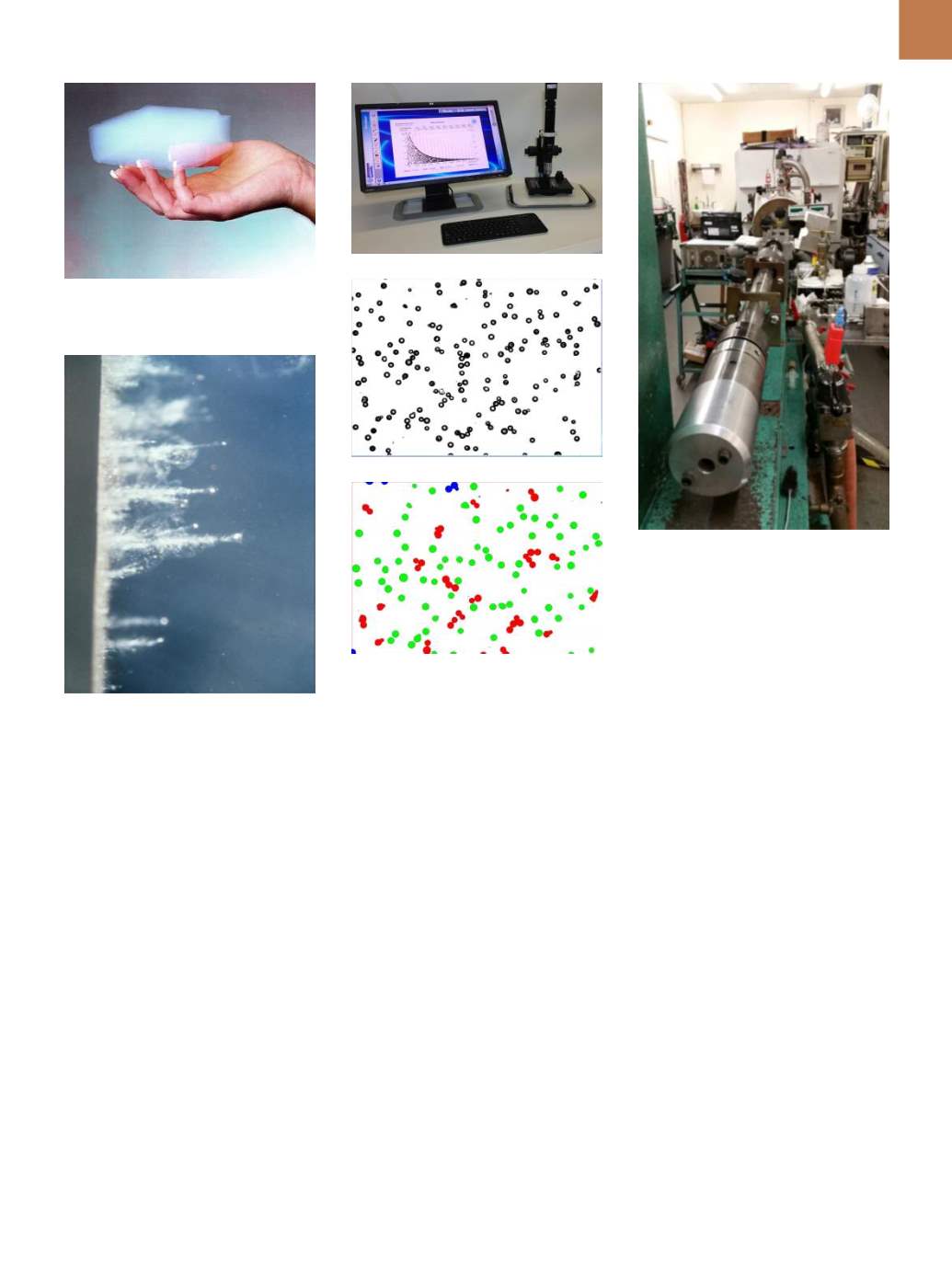

The hypervelocity gun features a

muzzle velocity up to 14,000 mph and

can fire simulated cosmic dust parti-

cles of sizes up to ~1 mm (Fig. 6). The

gun is a two-stage device comprising

a high pressure chamber followed by

an evacuated chamber to simulate the

space environment. In between the

two chambers sits a microcartridge,

measuring 4.3 mm diameter by 4.5 mm

long, which contains microspheres that

Fig. 3 —

Aerogel foam for capturing cosmic

dust.

Fig. 4 —

Cosmic dust penetrating aerogel

foam.

COSMIC DUST SIMULATION

Although cosmic dust is com-

prised of a range of different types of

mineral materials, it is mostly glassy in

nature, making glass microspheres a

useful experimentation model. In order

to determine the appropriate speed

to mimic conditions in space, micro-

spheres closest in size to the particles

recovered from space were used. These

microspheres were then fired into aero-

gel foam using a hypervelocity gas gun

developed at the University of Kent

(Fig. 4). The muzzle velocity was varied

until it matched the penetration depth

observed from the particles collected in

space.

During the initial work conduct-

ed at the University of Kent, individual

glass beads of similar size were col-

lected from broader sized glass beads

Fig. 5 —

ShapeSizer microscope (a), live

image (b), and digitized image (c); touching

and edge particles not counted.

Fig. 6 —

Hypervelocity gas gun.

(a)

(b)

(c)